Method for producing tert-butanol by hydration of isobutene in mixed n-butane

A technology for hydrating and mixing C4 in isobutene, applied in chemical instruments and methods, preparation of organic compounds, preparation of hydroxyl compounds, etc., can solve the problems of low isobutene conversion rate, low mutual solubility, etc., to reduce separation energy consumption, improve Reaction rate, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

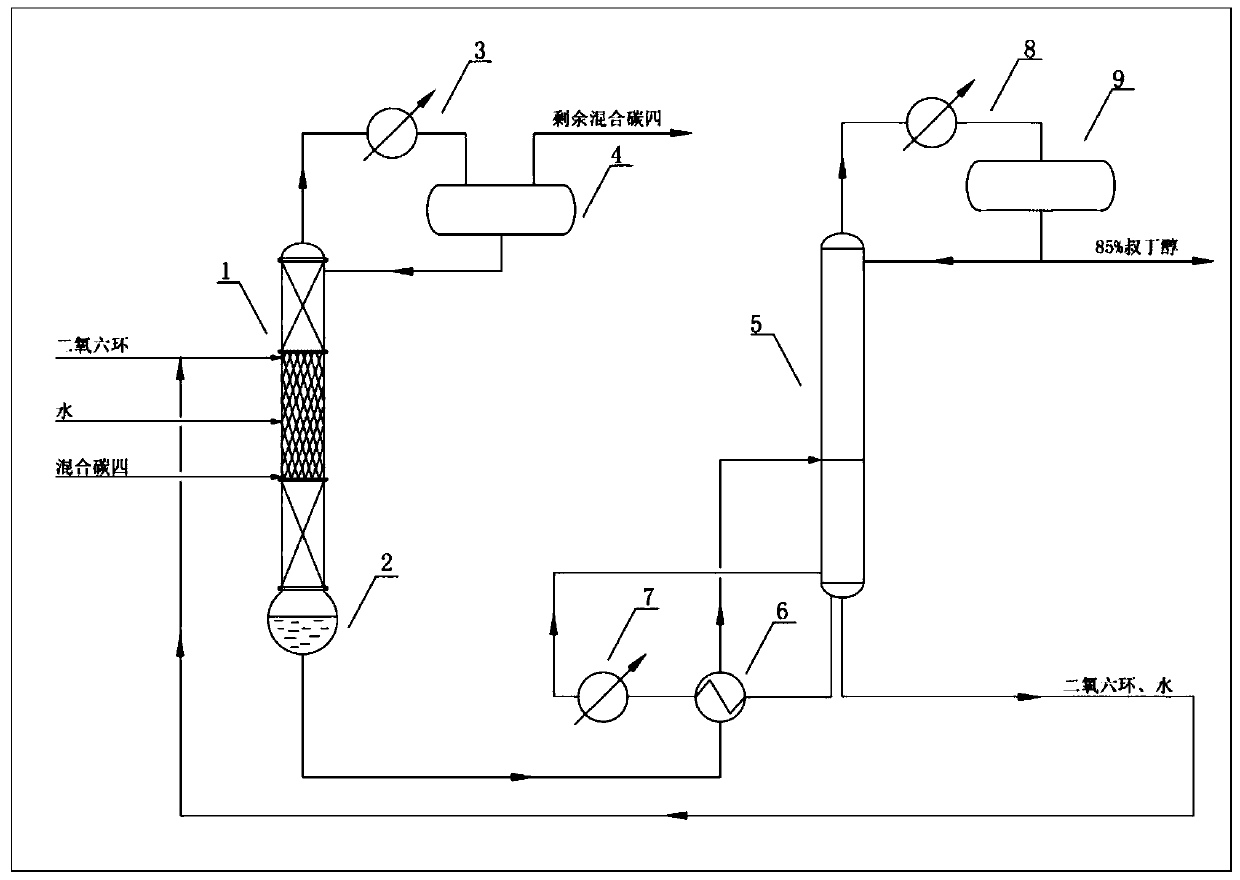

Image

Examples

Embodiment 1

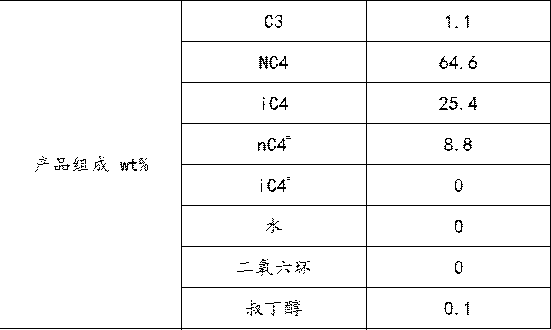

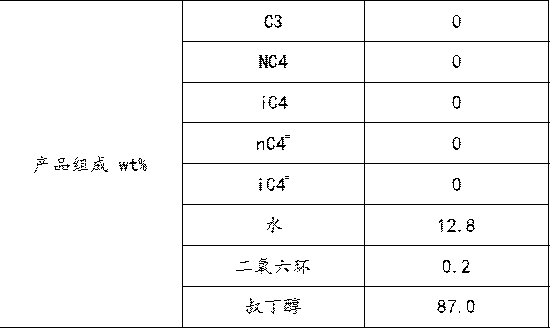

[0035] Add a mass fraction of 40% tert-butanol, 50% dioxane, and 10% water to the reactor of the reactive distillation tower to reach 70% of the liquid level in the tower reactor, add a certain amount of zeolite to prevent bumping, and heat the tower reactor. Control the heating power of the reactor of the reaction distillation tower to 5.4kW, and turn on the heat preservation switch of the tower body, control the pressure inside the tower to 0.5MPa, and start feeding when the temperature of the tower reactor reaches 98°C, and the total water feeding amount is 15mol / h , the feed rate of the total mixed carbon four is 26mol / h, wherein the isobutene is 10mol / h, the feed rate of dioxane is 10mol / h, and the feed temperature is room temperature. Until the reactive distillation column starts to reflux, stop the feed, and return to the total for about 30 minutes, then mix C4, water and dioxane to feed again. The reflux ratio of the reactive distillation tower is 5, and the production...

Embodiment 2

[0043]Add a mass fraction of 40% tert-butanol, 50% dioxane, and 10% water to the reactor of the reactive distillation tower to reach 70% of the liquid level in the tower reactor, add a certain amount of zeolite to prevent bumping, and heat the tower reactor. Control the heating power of the reactor of the reaction distillation tower to 5.4kW, and turn on the heat preservation switch of the tower body, control the pressure inside the tower to 0.5MPa, and start feeding when the temperature of the tower reactor reaches 98°C, and the total water feeding amount is 20mol / h , the feed rate of the total mixed carbon four is 26mol / h, wherein the isobutene is 10mol / h, the feed rate of dioxane is 10mol / h, and the feed temperature is room temperature. Until the reactive distillation column starts to reflux, stop the feed, and return to the total for about 30 minutes, then mix C4, water and dioxane to feed again. The reflux ratio of the reactive distillation tower is 5, and the output is 2...

Embodiment 3

[0051] Add a mass fraction of 40% tert-butanol, 50% dioxane, and 10% water to the reactor of the reactive distillation tower to reach 70% of the liquid level in the tower reactor, add a certain amount of zeolite to prevent bumping, and heat the tower reactor. Control the heating power of the reactor of the reaction distillation tower to 5.4kW, and turn on the heat preservation switch of the tower body, control the pressure inside the tower to 0.5MPa, and start feeding when the temperature of the tower reactor reaches 98°C, and the total water feeding amount is 15mol / h , the feed rate of the total mixed carbon four is 26mol / h, wherein the isobutene is 10mol / h, the feed rate of dioxane is 10mol / h, and the feed temperature is room temperature. Until the reactive distillation column starts to reflux, stop the feed, and return to the total for about 30 minutes, then mix C4, water and dioxane to feed again. The reflux ratio of the reactive distillation tower is 6, and the production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com