Desalting and decoloring method for cistanche total oligosaccharide

A technology for desalination and decolorization of Cistanche deserticola, applied in chemical instruments and methods, oligosaccharides, sugar derivatives, etc., can solve the problems of strong water solubility, small molecular weight of galactitol, difficult desalination treatment, etc. The effect of high adsorption capacity and decolorization capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The screening test of embodiment 1 resin

[0042] 1) Extraction: crush Cistanche deserticola, add 10 times the weight of pure water, heat and reflux for extraction 3 times, each time for 1.0 h, and combine the filtrates.

[0043] 2) Concentration: Concentrate under reduced pressure until the relative density reaches 1.15 (measured at 60°C), add 95% (v / v) ethanol solution to elute statically until the alcohol content reaches 50%, stand overnight, filter, and concentrate the filtrate under reduced pressure to 1.15 (measured at 50°C).

[0044] 3) Pretreatment of macroporous resin: Soak AB-8 macroporous resin with 95% (v / v) ethanol solution for 12 hours, first rinse with 95% (v / v) ethanol until the ethanol flowing out is free of turbidity, and then Wash with distilled water until there is no alcohol smell; then soak in 4% (v / v) HCl solution for 4 hours, wash with distilled water until neutral, then soak in 4% (v / v) NaOH solution for 4 hours, wash with distilled water until...

Embodiment 2

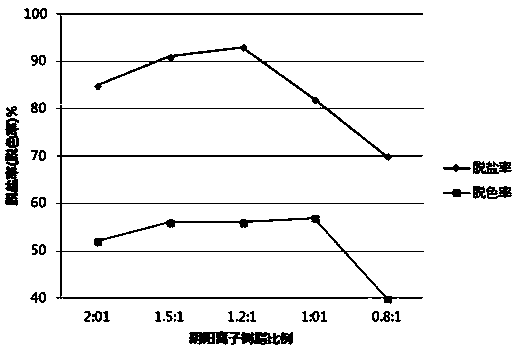

[0057] Example 2 Ionic resin desalination and decolorization dynamic adsorption test of Cistanche total oligosaccharides

[0058] Pack LS-840 acidic cation exchange resin and LS-850 basic anion exchange resin into columns according to the volume ratio of 2:1, 1.5:1, 1.2:1, 1:1, 0.8:1 respectively, according to LS-840 resin LS Sequential tandem of -850 resins. Take 100ml of Cistanche oligosaccharides prepared by the method in Example 1 (diluted with pure water to a concentration of 15%) and put it on the column, control the flow rate at 2BV / h, wait until the sugar content of the effluent is greater than 0, collect the eluate, and calculate the desalination rate and decolorization rate.

[0059] Depend on figure 1 It can be seen that the desalination effect is the best when the ratio of anion to cation resin is 1.2:1, and it also shows that the salts in the total oligosaccharides of Cistanche deserticola mainly exist in the form of weakly basic anions. The resin ratio has lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com