Thermal insulation curtain fabric

A fabric and curtain technology, applied in the field of textile fabrics, can solve the problems of poor waterproof performance, rising indoor temperature, flame retardant, heat insulation, sound insulation, antibacterial, mildew proof, waterproof, oil proof, antifouling, dustproof, Anti-static, poor wear resistance and other problems, to achieve the effect of low preparation cost, excellent air permeability and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

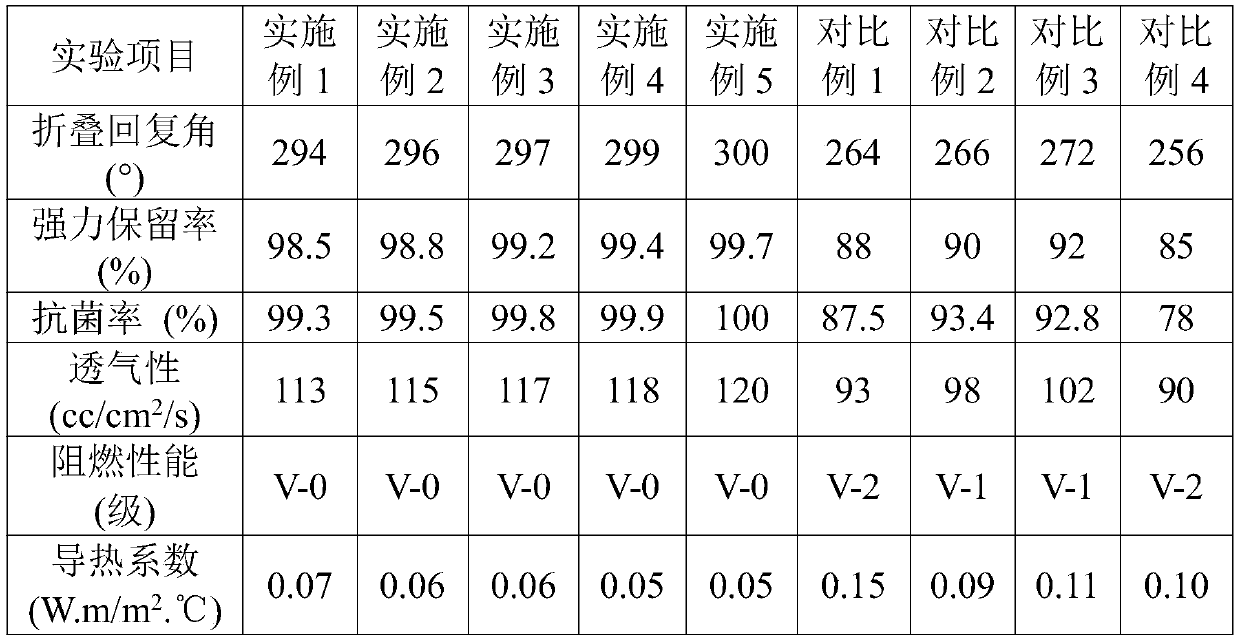

Examples

Embodiment 1

[0030] A heat-insulating curtain fabric, comprising a fabric base layer and a functional layer coated on the fabric base layer; the fabric base layer is made of the following fibers in parts by weight: 80 parts of modified fluorophenyl oxalamide-based polyester fiber, cotton and linen 10 parts of fiber, 10 parts of polyacrylonitrile fiber, 10 parts of bamboo charcoal fiber, 5 parts of graphene fiber; the functional layer is composed of double-ended epoxy silicone oil and 1,3-dihydroxyethyl-5,5-dimethyl Hydantoin is made by polycondensation reaction.

[0031] The preparation method of the modified fluorophenyl oxalamide-based polyester fiber comprises the steps of:

[0032] Preparation of polycondensate in Step S1: Add 1.62 kg of tetrafluoroisophthalic acid, 1 kg of N,N'-bis(2-hydroxyethyl) oxalamide and 0.3 kg of ethylene glycol antimony into the polymerization reactor, start stirring, and reduce the pressure Adjust the temperature to 0.4MPa, raise the temperature to 240°C fo...

Embodiment 2

[0038] A heat-insulating curtain cloth, comprising a cloth base layer and a functional layer coated on the cloth base layer; the cloth base layer is made of the following fibers in parts by weight: 85 parts of modified fluorophenyl oxalamide-based polyester fiber, cotton and linen 11 parts of fiber, 11 parts of polyacrylonitrile fiber, 11 parts of bamboo charcoal fiber, and 6 parts of graphene fiber; the functional layer is composed of double-ended epoxy silicone oil and 1,3-dihydroxyethyl-5,5-dimethyl Hydantoin is made by polycondensation reaction.

[0039] The preparation method of the modified fluorophenyl oxalamide-based polyester fiber comprises the steps of:

[0040] Preparation of polycondensate in Step S1: Add 1.62 kg of tetrafluoroisophthalic acid, 1 kg of N,N'-bis(2-hydroxyethyl) oxalamide and 0.35 kg of antimony acetate into the polymerization reactor, start stirring, and adjust the pressure to 0.45MPa, the temperature was raised to 245°C for esterification reactio...

Embodiment 3

[0046] A heat-insulating curtain cloth, comprising a cloth base layer and a functional layer coated on the cloth base layer; the cloth base layer is made of the following fibers in parts by weight: 90 parts of modified fluorophenyl oxalamide-based polyester fiber, cotton and linen 13 parts of fiber, 13 parts of polyacrylonitrile fiber, 12 parts of bamboo charcoal fiber, and 7 parts of graphene fiber; the functional layer is composed of double-ended epoxy silicone oil and 1,3-dihydroxyethyl-5,5-dimethyl Hydantoin is made by polycondensation reaction.

[0047] The preparation method of the modified fluorophenyl oxalamide-based polyester fiber comprises the steps of:

[0048] Preparation of polycondensate in step S1: Add 1.62 kg of tetrafluoroisophthalic acid, 1 kg of N,N'-bis(2-hydroxyethyl) oxalamide and 0.4 kg of antimony trioxide into the polymerization reactor, start stirring, and reduce the pressure Adjust the temperature to 0.5MPa, raise the temperature to 250°C for ester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com