Preparation method of nano aluminum powder with uniform particle size distribution

A technology of nano-aluminum powder and aluminum salt, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, and can solve the problem of easy-to-coat by-product LiCl impurities, expensive preparation methods, and easy-to-oxidize products and other problems, to achieve the effect of narrow particle size distribution, less loss and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to the preparation method of a kind of nano-aluminum powder provided by the present invention, described method comprises the following steps:

[0040] Step 1, weighing aluminum salt and solvent I in a reaction flask;

[0041] The aluminum salt is an aluminum salt soluble in water or an organic solvent, preferably a single aluminum salt or a compound salt of aluminum and an alkali metal, more preferably aluminum trichloride or lithium aluminum hydride;

[0042] The solvent I is a polar organic solvent, preferably an ether solvent, such as diethyl ether, methyl ethyl ether, tetrahydrofuran, epoxyhexane, alkoxybenzene, more preferably anisole.

[0043] In step 1, an auxiliary organophosphorus compound is also added, such as alkylphosphine, arylphosphine, alkylarylphosphine, preferably arylphosphine, more preferably triphenylphosphine.

[0044] The mol ratio of described aluminum salt and auxiliary agent is lithium aluminum hydride: aluminum trichloride: auxilia...

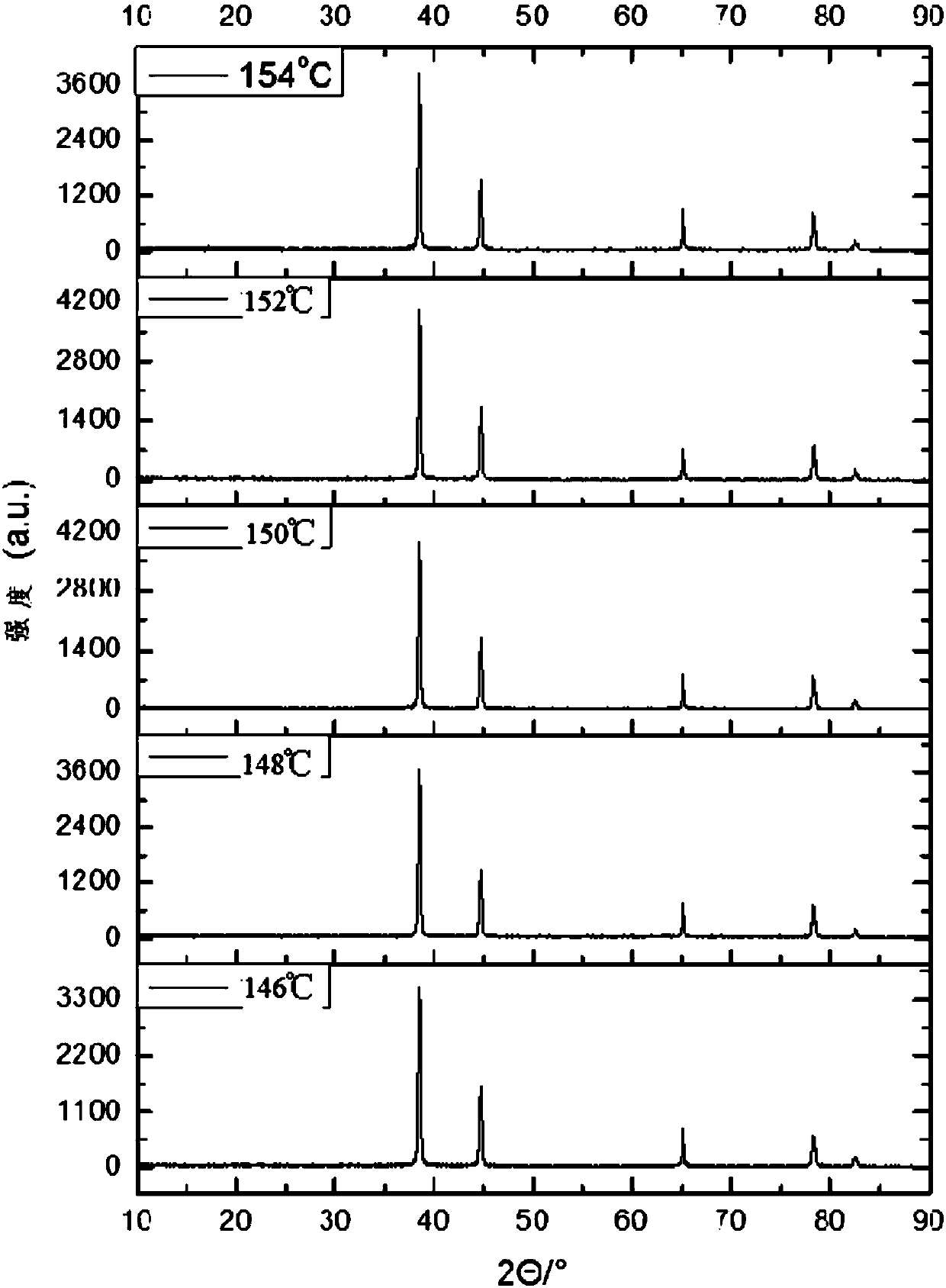

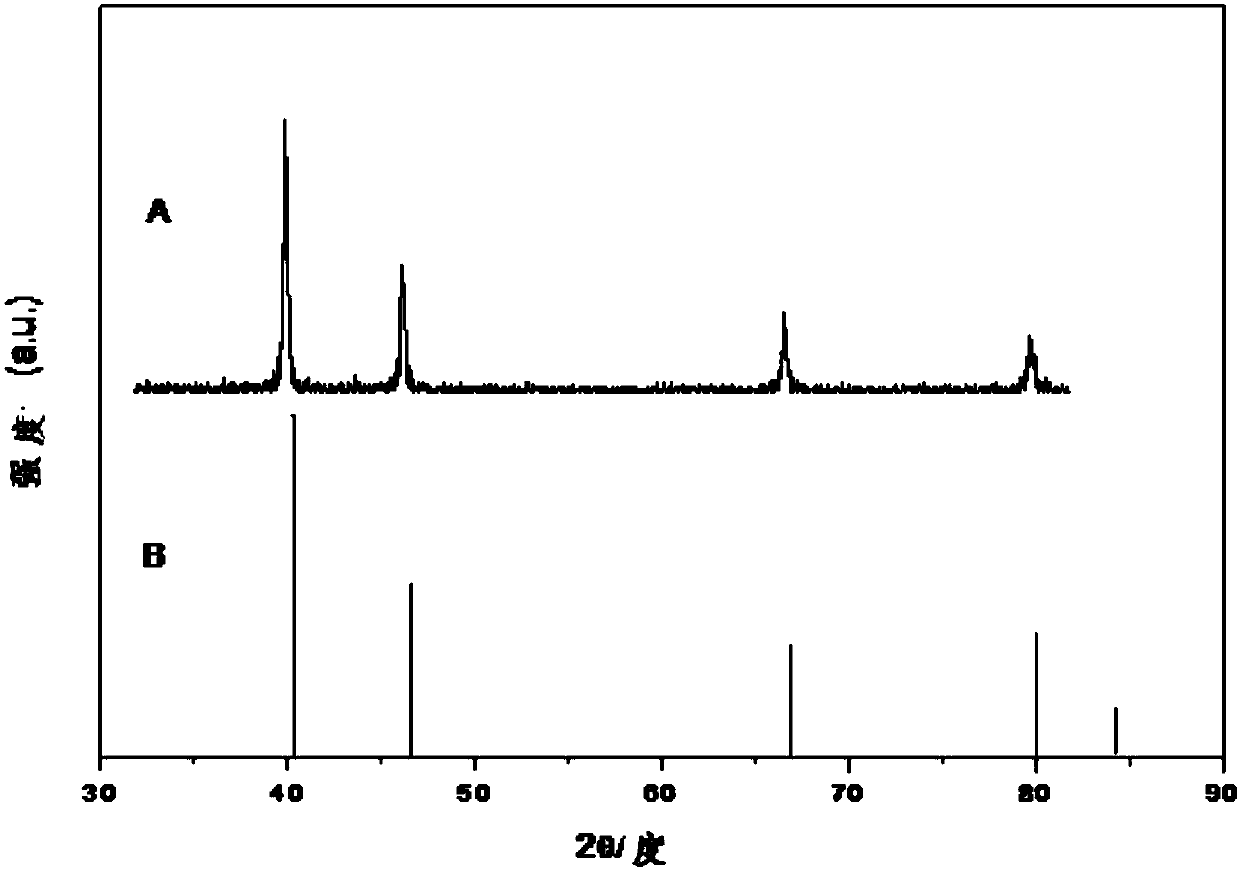

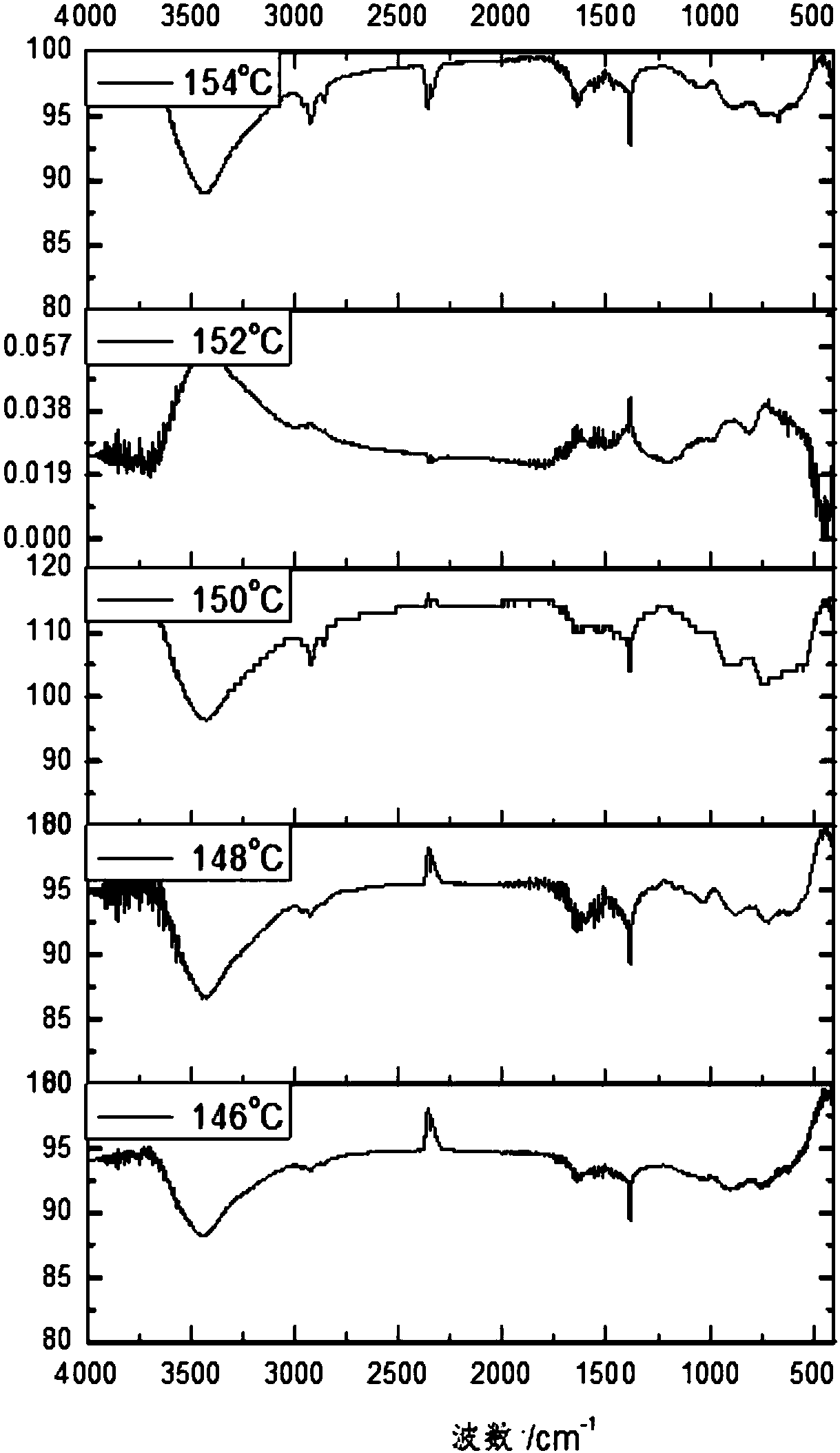

Embodiment 1

[0075] (1) Take a dry four-necked flask, after vacuuming, in a vacuum glove box, press anhydrous AlCl 3 The ratio of the molar ratio to triphenylphosphine (TPP) is 1:10, and 0.23g LiAlH is weighed with an electronic balance 4 and 5.25g triphenylphosphine (TPP), then measure 40mL anisole with a graduated cylinder, pour it into the bottle, add a stirring bar at the same time, and block the bottle mouth with four glass stoppers. Take another 0.27g of anhydrous AlCl 3 Add it into the dropper, and at the same time measure 10mL of anisole with a graduated cylinder, and pour it into the dropper. Put the four-neck flask and dropper into the ultrasonic machine for about 15 minutes to ensure that the AlCl 3 , AlLiH 4 and triphenylphosphine (TPP) are completely dissolved in anisole; then the four-neck flask is placed on an intelligent magnetic stirrer for heating and stirring; , a thermometer and a dropper, after the temperature rises to 146°C, turn the plunger of the dropper to drip...

Embodiment 2

[0078] The preparation steps are the same as in Example 1, except that the preparation reaction temperature is 148° C., and the obtained product nano-aluminum powder is marked as No. 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com