High-temperature-resistant plastic product and preparation method thereof

A technology for plastic products and high temperature resistance, applied in the field of plastic products, can solve problems such as inability to use normally, difficulty in recycling, poor heat resistance, etc., achieve excellent long-term high temperature resistance effect, best anti-oxidation effect, increase heat loss and The effect of heat transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

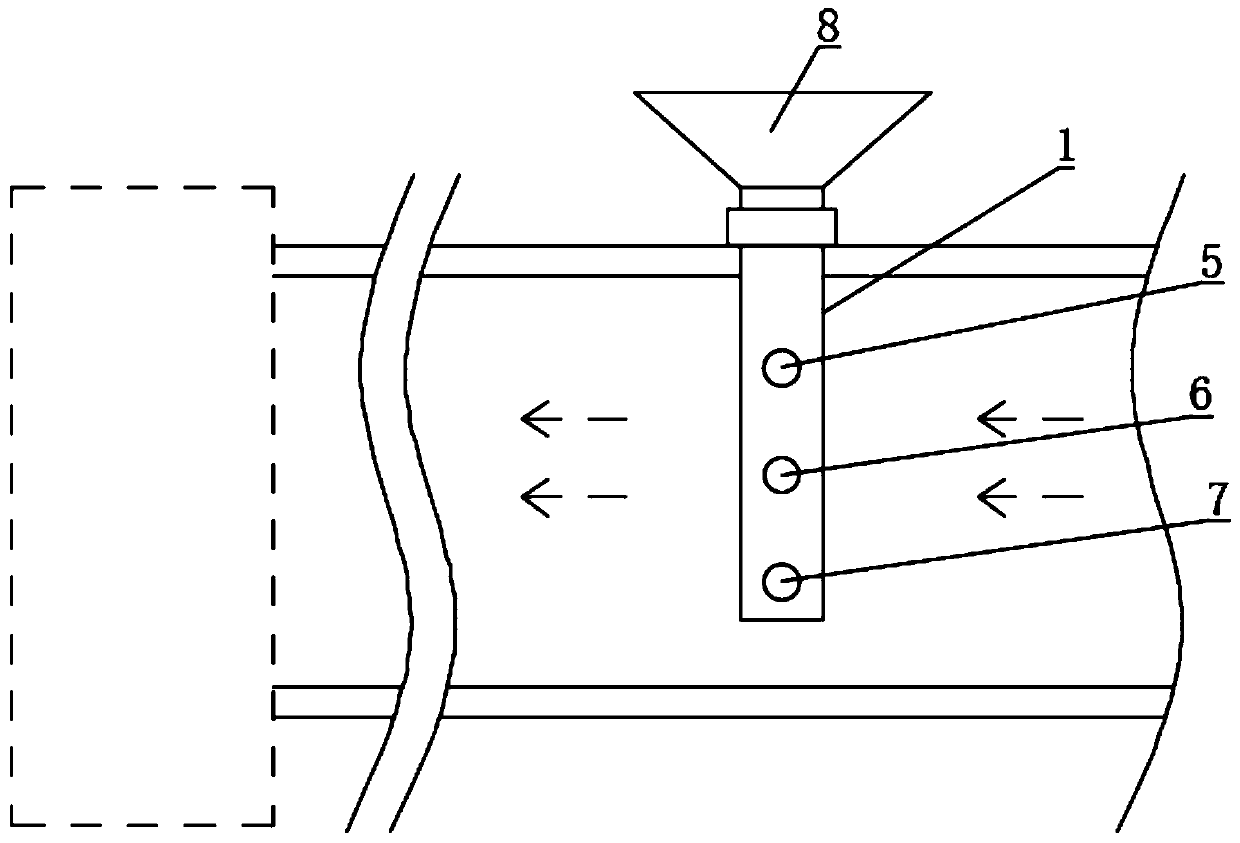

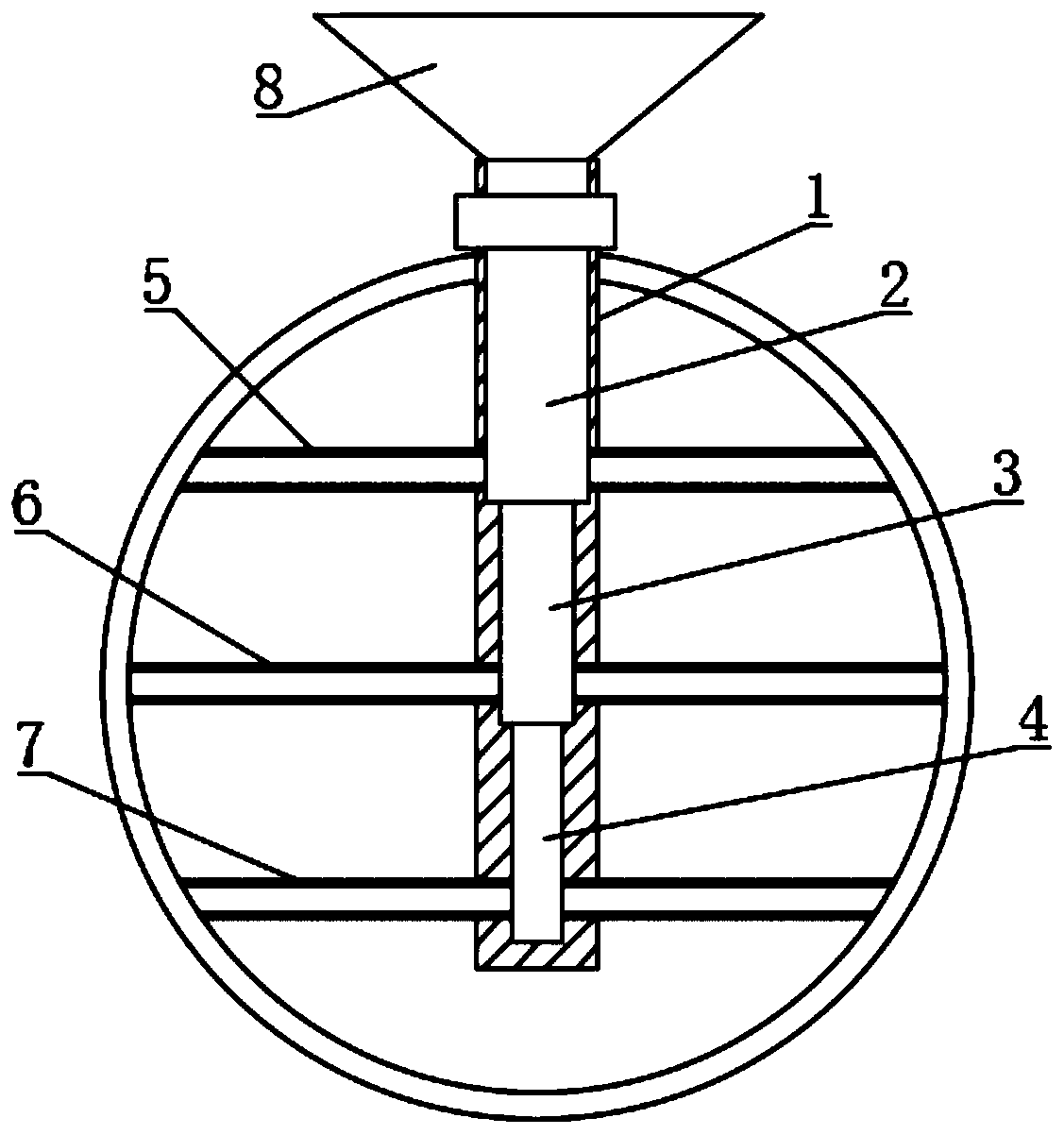

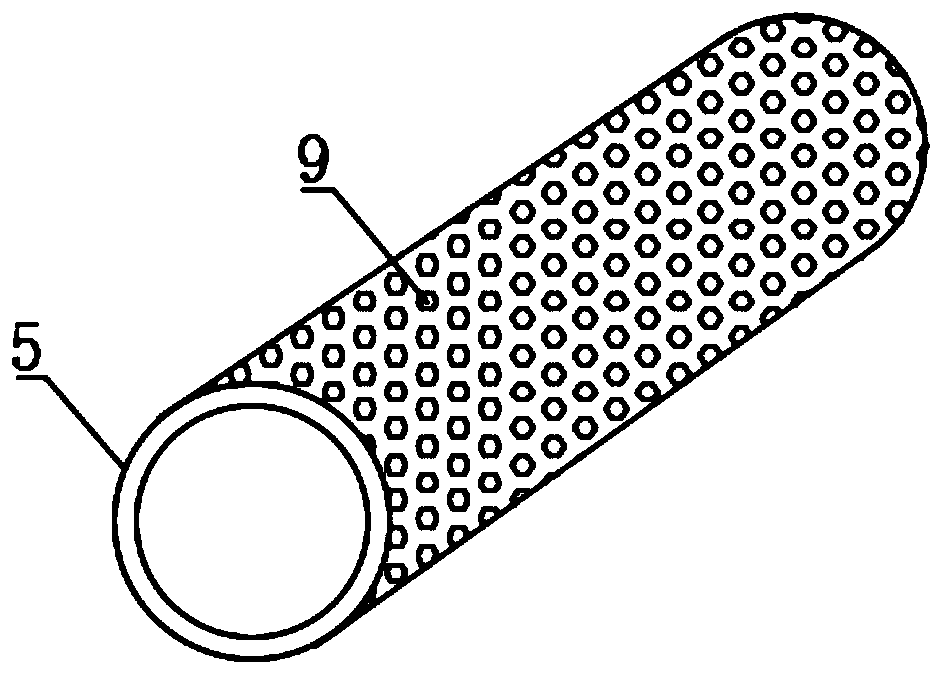

Method used

Image

Examples

Embodiment 1

[0042] A high-temperature-resistant plastic product, including thermoplastic polymers, fillers, fillers, plasticizers, stabilizing agents, foaming agents and chemical high-temperature insulation particles, thermoplastic polymers include polytetrafluoroethylene, low-density polyethylene, polypropylene and Polyimide, fillers include clay, talc, sodium silicate powder and calcium carbonate powder, extenders include glass fiber, titanium dioxide and silicone oil, plasticizers include aliphatic dibasic acid esters and phosphate esters, stabilizers include heat Stabilizers, light stabilizers and antioxidants, heat stabilizers are made of complex metal salts, light stabilizers are ultraviolet absorbers, antioxidants are mixtures of phenols and phosphorus compounds, the quality of phenols and phosphorus compounds The ratio is 2:1, phenols are the main antioxidants, the function is to capture the active free radicals generated in the oxidative degradation, thereby interrupting the chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com