Fermented feed and preparation method thereof

A technology of fermented feed and base material, applied in the field of aquaculture, can solve the problems of unscientific fermentation process, incomplete use of the advantages of fermented feed, unreasonable selection of strains, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0030] Embodiment 1-6 fermented feed

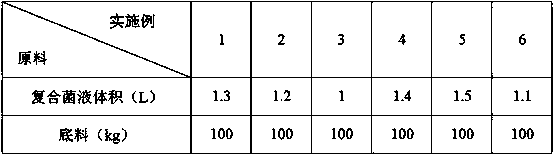

[0031] Embodiment 1-6 is respectively a kind of fermented feed, makes their raw material specific components as shown in table 1:

[0032] The raw material component of table 1 embodiment 1-6

[0033]

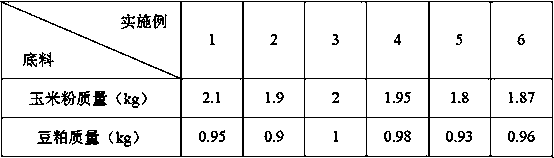

[0034] Wherein, the concrete component of primer is as shown in table 2:

[0035] The bottom material component of table 2 embodiment 1-6

[0036]

[0037] The specific components of the composite bacterial solution are shown in Table 3:

[0038] Table 3 Composite bacteria liquid components of Examples 1-6

[0039] .

Embodiment 7

[0040] Embodiment 7 A kind of preparation method of fermented feed

[0041] This embodiment is the preparation method of fermented feed in 1-6, and raw material is made up of any one in embodiment 1-6, and this preparation method is carried out according to the following sequence of steps:

[0042] 1) Cultivate Candida utilis, Bacillus natto, Saccharomyces cerevisiae and plant lactic acid bacteria respectively to obtain Candida utilis liquid, Bacillus natto liquid, Saccharomyces cerevisiae liquid and plant Lactobacillus liquid; Put Candida utilis liquid, Bacillus natto liquid, Saccharomyces cerevisiae liquid and Lactobacillus plantarum liquid into the triangular flask, vibrate to make uniform Candida utilis suspension, Bacillus natto suspension , Saccharomyces cerevisiae suspension and Lactobacillus plantarum suspension.

[0043] 2) Put Candida utilis suspension, Bacillus natto suspension, Saccharomyces cerevisiae suspension and plant lactic acid bacteria suspension into ster...

Embodiment 8-12

[0045] The preparation method of embodiment 8-12 fermented feed

[0046] Embodiment 8-12 is respectively a kind of preparation method of fermented feed, and the preparation method of embodiment 7 is basically the same, and difference is that the technical parameter of preparation process is different, and concrete parameter is as shown in table 4:

[0047] Table 4 Preparation process and parameters of Examples 8-12

[0048] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com