A kind of processing method of sweet potato leaf pickles

A processing method and a sweet potato leaf technology are applied to the processing field of sweet potato leaf pickles, can solve the problems of incomplete development and utilization, low utilization rate of sweet potato leaves, etc., and achieve the effects of stable and good quality, unique taste, and avoiding harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

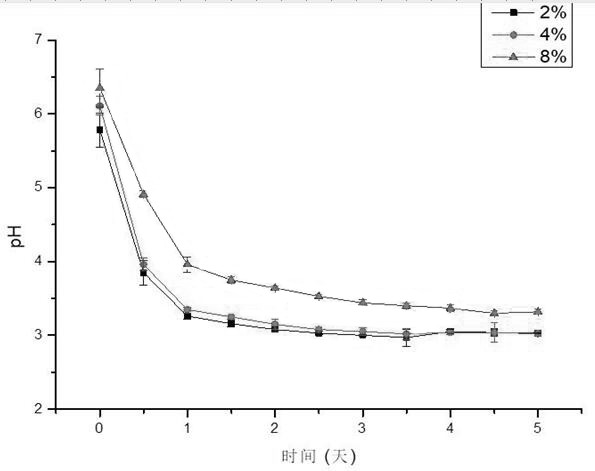

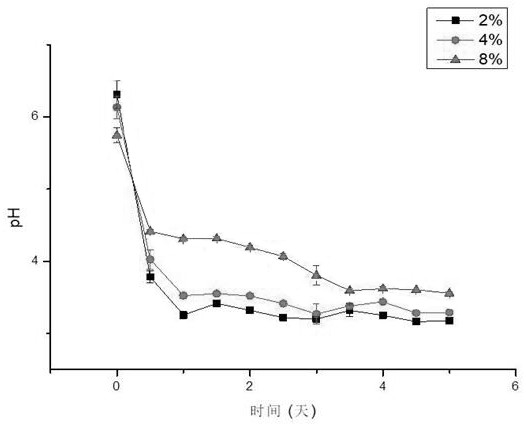

Image

Examples

preparation example Construction

[0060] Preparation of colorant: First, weigh food-grade copper chlorophyll sodium salt at 0.5g / kg, first dilute copper chlorophyll sodium salt with distilled water into a paste, then fully dilute it with demineralized water, and let stand for 2-4 hours Make it fully dissolved to reach the maximum saturation; secondly, add the solution in the fermenter to the copper chlorophyll sodium salt solution to adjust the acidity adaptively, fully stir during the mixing process, and the stirring time is in the range of 30-45min to make the pH value For 5.5-6.0, the colorant is obtained;

[0061] Step 4, changing the tank for coloring: take out the fermentation liquid in the fermentation tank after the fermentation is terminated, pour it into the coloring tank, add the prepared colorant to the coloring tank, and make the mass ratio of copper chlorophyll sodium salt and water in the coloring tank. 0.3-0.5:1000, after stirring evenly, add the sweet potato leaves in the fermentation tank to ...

Embodiment 1

[0065] A processing method of sweet potato leaf pickles, comprising the following steps:

[0066] Step 1. Preparation of sweet potato leaves before fermentation:

[0067] (1) Selection of raw materials: Select the tender leaves on the top and both sides of the sweet potato vine to ensure that the tender leaves of the sweet potato are intact and fresh, the leaves are wide and green, tender, with few crude fibers, no rot and mildew, and keep the petiole length of 5- 7cm;

[0068] (2), cleaning treatment: wash the selected sweet potato leaves with clean water; drain the cleaned sweet potato leaves to dry, soak them in demineralized water for 5 minutes, and remove the water; avoid damage to the sweet potato leaves during operation;

[0069] (3) Binding and color protection: after drying the cleaned sweet potato leaves, press 15-20 sweet potato leaves / bundle, and use cotton thread to bind the sweet potato leaves; put the bundled sweet potato leaves into the mass concentration of 0...

Embodiment 2

[0087] A processing method of sweet potato leaf pickles, comprising the following steps:

[0088] Step 1. Preparation of sweet potato leaves before fermentation:

[0089] (1) Selection of raw materials: Select the tender leaves on the top and both sides of the sweet potato vine to ensure that the tender leaves of the sweet potato are intact and fresh, the leaves are wide and green, tender, with few crude fibers, no rot and mildew, and keep the petiole length of 5- 7cm;

[0090] (2), cleaning treatment: wash the selected sweet potato leaves with clean water; drain the cleaned sweet potato leaves to dry, soak them in demineralized water for 10 minutes, and remove the water; avoid damage to the sweet potato leaves during operation;

[0091] (3), bundling and color protection: after drying the cleaned sweet potato leaves, press 15-20 sweet potato leaves / bundle, and use cotton thread to tie the sweet potato leaves; put the bundled sweet potato leaves into a mass concentration of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com