Preparation method of metal oxide suspension and method for spraying suspension to form high-specific-surface-area gas-sensitive coating under liquid material flame

A technology of oxides and suspensions, which is applied in the fields of engineering and material science, can solve the problems of good preservation and difficulty in hollow structural materials, and achieve the effects of low cost, large specific surface area, and excellent gas-sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

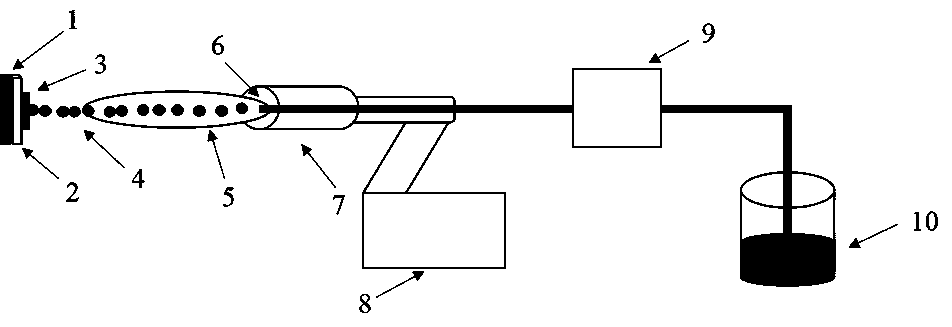

Method used

Image

Examples

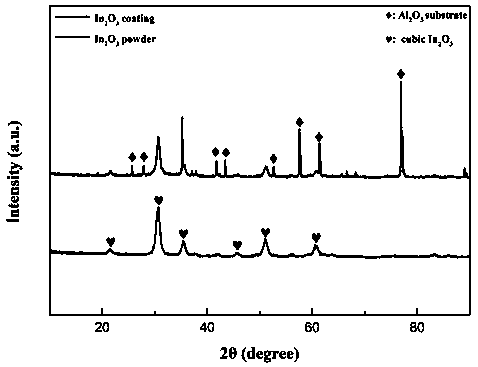

Embodiment 1

[0030]1. Using alumina as the insulating matrix, the alumina flakes were placed in deionized water and ethanol in sequence, and assisted by ultrasonic waves, cleaned for 10 minutes, and dried for later use. Using the method of vacuum coating and metal mask pattern, a layer of chromium is firstly prepared to improve the bonding strength, and then a layer of gold is vapor-deposited on the front side of the aluminum oxide sheet to obtain interdigitated electrodes. On the opposite side of the aluminum oxide sheet, a layer of chromium is first prepared by vacuum coating to improve the bonding strength, and then a layer of platinum is evaporated on the front of the aluminum oxide sheet to obtain an interdigital heating electrode, that is, the sensor substrate 2 .

[0031] 2. Under magnetic stirring at 60°C, weigh DL-aspartic acid, dissolve it in deionized water and stir for 10 min, add PEG-4000 solution and continue stirring for 30 min. Then add In(NO 3 ) 3 The solution and urea...

Embodiment 2

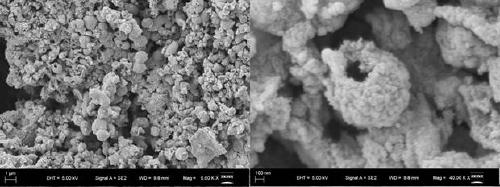

[0035] The difference between this example and Example 1 is that the flow rate of the liquid material selected in step 3 is 40mL / min, preheating is carried out at 400 °C before spraying, the oxygen flow rate is adjusted to obtain a neutral flame, and the spraying distance is 250 mm. , the hollow micro-nano structure In with a thickness of 22 µm was prepared 2 o 3 coating. When the test condition is 25°C, the coating is resistant to 10 ppm NO 2 The sensitivity is 32.5.

Embodiment 3

[0037] The difference between this embodiment and Example 1 is that: 100 mL 0.3 mol / L Zn(NO 3 ) 3 solution. The flow rate of the liquid material selected in step 3 is 40mL / min, preheated at 500 °C before spraying, and the oxygen flow rate is adjusted to obtain an oxidation flame. When the spraying distance is 250 mm, a hollow micro-nano structure ZnO coating with a thickness of 25 μm is prepared. Floor. When the test conditions are room temperature, the coating is 10 ppm NO 2 The sensitivity is 26.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com