A kind of non-isocyanate polyurethane modified alkyd resin and preparation method thereof

A polyurethane-modified, non-isocyanate technology, applied in the non-isocyanate polyurethane-modified alkyd resin and its preparation, in the field of polyurethane-modified alkyd resin, can solve the problems of difficulty and inconvenience in the production process of material transportation, storage, and achieve fast hardness development , great application potential, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a 2L four-necked flask equipped with a stirrer, a thermometer and a condenser, 208 g of glycerol carbonate and 53 g of ethylenediamine were added to react at 30° C. for 4 h. Then, 330 g of soybean oleic acid and 141 g of phthalic anhydride were added, the temperature was raised to 180° C. for reaction for 40 minutes, and then the temperature was raised to 240° C. to react until the acid value was less than 10mkgKOH / g. When the temperature was lowered to 180°C for 30min, 732g of 200# solvent was added to dilute to obtain a non-isocyanate polyurethane modified alkyd resin.

Embodiment 2

[0021] In a 2L four-necked flask equipped with a stirrer, a thermometer and a condenser, 208 g of glycerol carbonate and 150 g of isophorone diamine were added to react at 30°C for 5 hours. Then, 330 g of soy oleic acid and 158 g of terephthalic acid were added, the temperature was raised to 180° C. for reaction for 40 min, and then the temperature was raised to 240° C. to react until the acid value was less than 10mkgKOH / g. When the temperature was lowered to 180°C for 30min, 846g of 200# solvent was added to dilute to obtain a non-isocyanate polyurethane modified alkyd resin.

Embodiment 3

[0023] In a 2L four-necked flask equipped with a stirrer, a thermometer and a condenser, 208 g of glycerol carbonate and 102 g of hexamethylenediamine were added to react at 30°C for 4 hours. Then, 330 g of linoleic acid and 158 g of isophthalic acid were added, the temperature was raised to 180° C. for reaction for 40 min, and then the temperature was raised to 240° C. to react until the acid value was less than 10mkgKOH / g. When the temperature was lowered to 180°C for 30min, 749g of 200# solvent was added to dilute to obtain a non-isocyanate polyurethane modified alkyd resin.

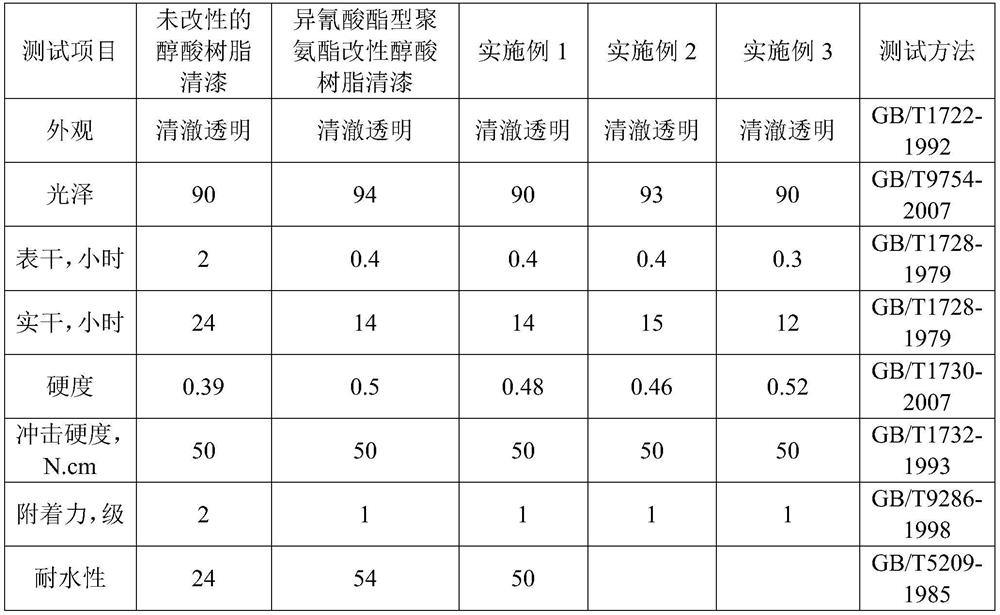

[0024] Unmodified alkyd resin, isocyanate type polyurethane modified alkyd resin and non-isocyanate polyurethane modified alkyd resin were made into varnish, and the performance comparison is shown in Table 1. Compared with unmodified alkyd resin, polyurethane modified alkyd resin has faster hardness development and better corrosion resistance. The performance of the non-isocyanate polyurethane modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com