Ion crosslinking ethylene propylene diene monomer and preparation method thereof

An EPDM rubber and ion cross-linking technology, which is applied in the field of polymer materials, can solve the problems of unfavorable ion cross-link formation, high price, and inability to really enter the domestic market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

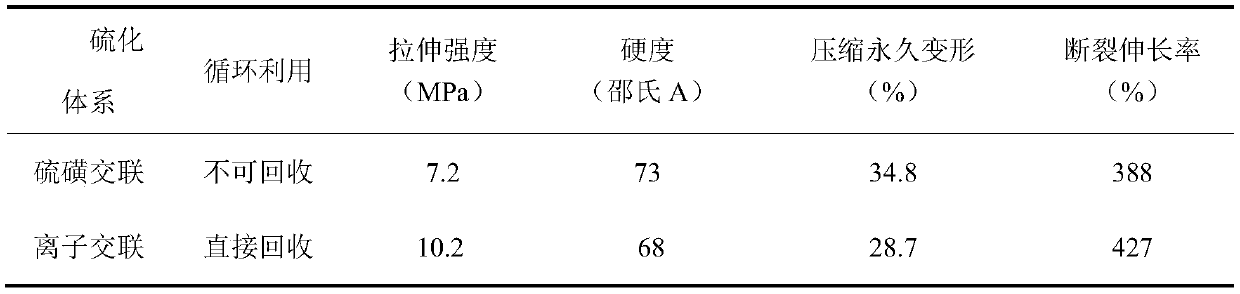

Examples

Embodiment 1

[0017] Embodiment 1: The preparation of ionically crosslinked modified EPDM rubber comprises the following steps:

[0018] Weigh 1 mole part of toluene diisocyanate (MDI) and dissolve it in xylene, raise the temperature to 60°C, then add 1 mole part of furfuryl alcohol (FA) dropwise, keep warm for 3 hours and cool down to precipitate furfuryl alcohol-toluene diisocyanate (FA -MDI), spare.

[0019] Dissolve 100 parts by mass of EPDM in 500 parts by mass of xylene, add 3 parts by mass of maleic anhydride, heat to 100°C, add dropwise 2 parts by mass of dibenzoyl peroxide dissolved in xylene, and keep warm After reacting for 2 hours, it was cooled, and the solvent was distilled off to obtain carboxylic acid grafted EPDM: EPDM-g-MAH.

[0020] 100 mass parts of grafted EPDM-g-MAH was added to 10 mass parts of FA-MDI and mechanically blended in an internal mixer for 3 hours, then 5 mass parts of bismaleimide and 1 mass part of stearin were added Zinc acid was refined at 100°C for 2...

Embodiment 2

[0021] Embodiment 2: Concrete preparation operation is the same as embodiment 1. The formula of ion-crosslinked modified EPDM rubber is 100 mass parts of EPDM, 2 mass parts of dibenzoyl peroxide, 6 mass parts of maleic anhydride, 10 mass parts of FA-MDI, 5 mass parts of bismaleic acid Zinc stearate of imine and 1.2 mass parts, internal mixer refining temperature 130 degrees centigrade, refining time 1 hour.

Embodiment 3

[0022] Embodiment 3: Concrete preparation operation is the same as embodiment 1. The formula of ion-crosslinked modified EPDM rubber is 100 mass parts of EPDM, 3 mass parts of di-tert-butylperoxycumene, 5 mass parts of maleic anhydride, 8 mass parts of FA-MDI, 5 mass parts of bismaleimide and 0.8 parts by mass of zinc stearate, the refining temperature of the internal mixer is 120° C., and the refining time is 90 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com