Heat-vulcanized adhesive and preparation method thereof

An adhesive, thermal vulcanization technology, applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve the problems of poor adhesion, peel strength, poor adhesion, etc. The effect of large-scale promotion, superior tensile strength performance and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

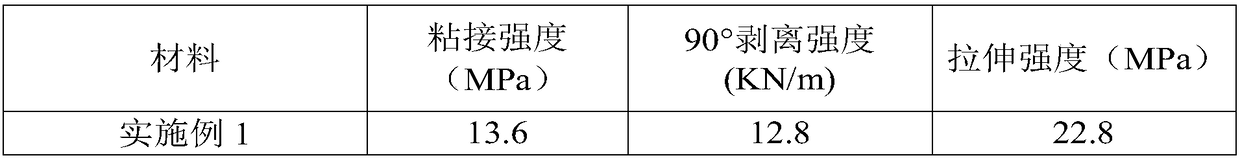

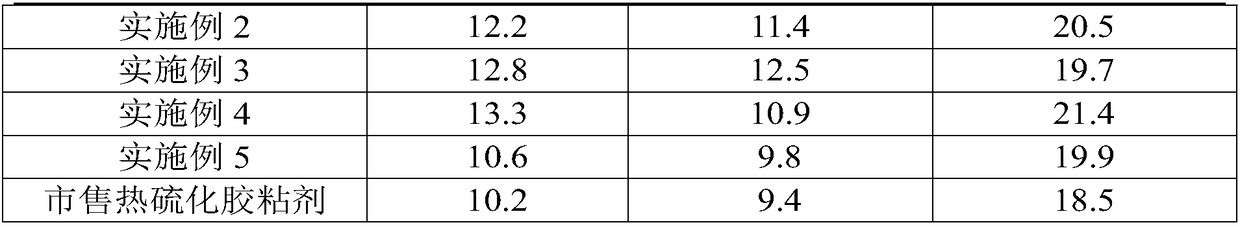

Examples

Embodiment 1

[0030] A kind of thermal vulcanization adhesive and preparation method thereof

[0031] Composition of heat vulcanizing adhesive raw materials:

[0032] Phenoxy resin 3.3kg, methyl vinyl silicone rubber 2.0kg, stearic acid 6.0kg, zinc oxide powder 0.35kg, activated calcium carbonate 0.4kg, accelerator DM0.10kg, accelerator TMTD0.05kg, sulfur 0.15kg, vulcanization Agent PM0.06kg, nano titanium dioxide 0.1kg.

[0033] The preparation of active calcium carbonate comprises the following steps:

[0034] Step 1, put the nano-calcium carbonate powder in a muffle furnace, and bake at 450° C. for 12 hours under an air atmosphere;

[0035] Step II, put the nano-calcium carbonate powder obtained in step I into the sodium fatty acid solution, feed carbon dioxide, adjust the pH of the solution to 5-6, control the activation temperature to 70°C, and activate for 15 minutes;

[0036] In step III, the nano-calcium carbonate powder obtained in step II is filtered and dried to obtain active ...

Embodiment 2

[0043] A kind of thermal vulcanization adhesive and preparation method thereof

[0044] Composition of heat vulcanizing adhesive raw materials:

[0045] 2.5kg of phenoxy resin, 2.5kg of methyl vinyl silicone rubber, 0.3kg of stearic acid, 0.3kg of zinc oxide powder, 0.5kg of activated calcium carbonate, 0.3kg of accelerator D, 0.12kg of sulfur, 0.04kg of vulcanizing agent PM, nano Titanium dioxide 0.2kg.

[0046]The activation process of active calcium carbonate includes the following steps:

[0047] The preparation of active calcium carbonate comprises the following steps:

[0048] Step 1, put the nano-calcium carbonate powder in a muffle furnace, and bake at 600° C. for 8 hours in an air atmosphere;

[0049] Step II, put the nano-calcium carbonate powder obtained in step I into the sodium fatty acid solution, feed carbon dioxide, adjust the pH of the solution to 5-6, control the activation temperature at 80°C, and activate for 10 minutes;

[0050] In step III, the nano-c...

Embodiment 3

[0057] A kind of thermal vulcanization adhesive and preparation method thereof

[0058] Composition of heat vulcanizing adhesive raw materials:

[0059] Phenoxy resin 4.0kg, methyl vinyl silicone rubber 1.5kg, stearic acid 0.5kg, zinc oxide powder 0.4kg, activated calcium carbonate 0.1kg, accelerator TMTM0.03kg, accelerator DM0.03kg, accelerator TMTD0.04kg , sulfur 0.18kg, vulcanizing agent PM0.08kg, nano-titanium dioxide 0.01kg.

[0060] The preparation of active calcium carbonate comprises the following steps:

[0061] Step 1, put the nano-calcium carbonate powder in a muffle furnace, and bake at 500° C. for 12 hours under an air atmosphere;

[0062] Step II, put the nano-calcium carbonate powder obtained in step I into the sodium fatty acid solution, feed carbon dioxide, adjust the pH of the solution to 5-6, control the activation temperature to 75°C, and activate for 15 minutes;

[0063] In step III, the nano-calcium carbonate powder obtained in step II is filtered and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com