Boron diffusion back passivation process for p-type crystalline silicon solar cells

A solar cell and back passivation technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of unstable open circuit voltage and conversion efficiency of cells, unsatisfactory effects, and poor square resistance uniformity. The effect of improving the uniformity of the square resistance, the uniformity of the square resistance between the chips, and the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

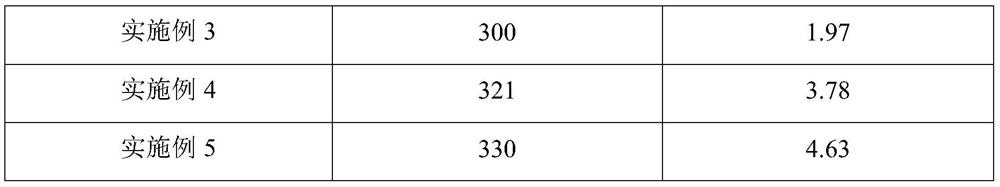

Examples

Embodiment 1

[0040] ⑴Start: In the equipment preparation stage, the preparation time is 10s, the set temperature in the furnace tube is 800°C, and the flow rate of large nitrogen is 10000scm.

[0041] (2) Boat release: Send the quartz boat loaded with silicon wafers into the furnace tube, the running time is 440s, the temperature in the furnace tube is set at 820°C, and the flow rate of nitrogen is 10000 sccm.

[0042] (3) Heating: the temperature in the furnace tube rises rapidly to 830°C within 200s, and the flow rate of nitrogen in the furnace tube is 10000 sccm.

[0043] (4) Oxidation: The temperature in the furnace tube is set to 830°C, the oxygen flow rate is 900 sccm, the maximum nitrogen flow rate is 10000 sccm, and the oxidation duration is 240s.

[0044] (5) Constant temperature for the first time: The temperature in the furnace tube rises rapidly to 900°C within 600s, and keeps warm after reaching 900°C. The flow rate of large nitrogen in the furnace tube is 10000 sccm.

[0045...

Embodiment 2

[0057] ⑴Start: In the equipment preparation stage, the preparation time is 10s, the set temperature in the furnace tube is 800°C, and the flow rate of large nitrogen is 10000scm.

[0058] (2) Boat release: Send the quartz boat loaded with silicon wafers into the furnace tube, the running time is 440s, the temperature in the furnace tube is set at 820°C, and the flow rate of nitrogen is 10000 sccm.

[0059] (3) Heating: the temperature in the furnace tube rises rapidly to 830°C within 200s, and the flow rate of nitrogen in the furnace tube is 10000 sccm.

[0060] (4) Oxidation: The temperature in the furnace tube is set to 830°C, the oxygen flow rate is 1100 sccm, the maximum nitrogen flow rate is 10000 sccm, and the oxidation duration is 240s.

[0061] (5) Constant temperature for the first time: The temperature in the furnace tube rises rapidly to 900°C within 600s, and keeps warm after reaching 900°C. The flow rate of large nitrogen in the furnace tube is 10000 sccm.

[006...

Embodiment 3

[0074] ⑴Start: In the equipment preparation stage, the preparation time is 10s, the set temperature in the furnace tube is 800°C, and the flow rate of large nitrogen is 10000scm.

[0075] (2) Boat release: Send the quartz boat loaded with silicon wafers into the furnace tube, the running time is 440s, the temperature in the furnace tube is set at 820°C, and the flow rate of nitrogen is 10000 sccm.

[0076] (3) Heating: the temperature in the furnace tube rises rapidly to 830°C within 200s, and the flow rate of nitrogen in the furnace tube is 10000 sccm.

[0077] (4) Oxidation: The temperature in the furnace tube is set to 830°C, the oxygen flow rate is 900 sccm, the maximum nitrogen flow rate is 10000 sccm, and the oxidation duration is 240s.

[0078] (5) Constant temperature for the first time: The temperature in the furnace tube rises rapidly to 900°C within 600s, and keeps warm after reaching 900°C. The flow rate of large nitrogen in the furnace tube is 10000 sccm.

[0079...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com