Oxygen reduction electrocatalyst for aromatic diazonium salt surface modified MXene loaded platinum and preparation method of oxygen reduction electrocatalyst

A surface modification and electrocatalyst technology, which is applied in nanotechnology, circuits, electrical components, etc. for materials and surface science, to achieve the effect of enhancing interaction force, cheap and easy-to-obtain raw materials, and alleviating the effect of easy corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

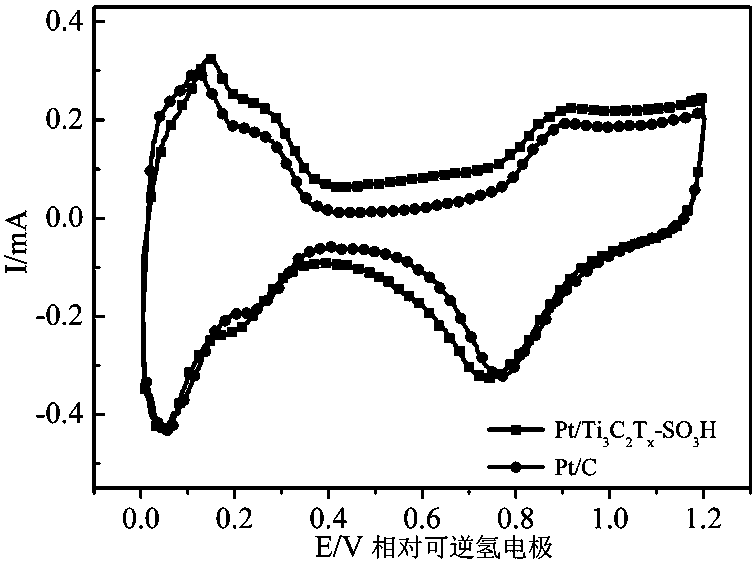

Image

Examples

Embodiment 1

[0030] First, 4.8 g of LiF was added to 60 mL of hydrochloric acid solution with a concentration of 9 mol / L contained in a polytetrafluoroethylene beaker at room temperature, and LiF was fully dissolved after continuous magnetic stirring for 15 min, and then 3 g of Ti 3 AlC 2 Slowly add the powder into the above solution for 30 minutes, heat up to 60°C and react for 48 hours. After the reaction, the mixture is washed with deionized water and centrifuged at 3500 rpm for 5 minutes. Repeat the cleaning and centrifugation for 5 times. The supernatant after each centrifugation was poured out as waste liquid, and fresh deionized water was added until the pH value of the supernatant was neutral, and then the obtained precipitate was vacuum-dried at 60°C with nitrogen for 12 hours to obtain two Viti 3 C 2 Nano powder;

[0031] Then weigh 0.3g two-dimensional Ti 3 C 2 The powder was dispersed in 100 mL of water, and the aqueous dispersion of the two-dimensional Ti3C2 powder was ob...

Embodiment 2

[0034] First, 2 g of LiF was added to 60 mL of hydrochloric acid solution with a concentration of 9 mol / L contained in a polytetrafluoroethylene beaker at room temperature, and the LiF was fully dissolved after continuous magnetic stirring for 15 min, and then 2 g of Ti 3 AlC 2 Slowly add the powder into the above solution for 30 minutes, heat up to 35°C and react for 72 hours. After the reaction, the mixture is washed with deionized water and centrifuged at 3500 rpm for 5 minutes. Repeat the cleaning and centrifugation for 6 times. The supernatant after each centrifugation was discarded as a waste liquid, and fresh deionized water was added until the pH value of the supernatant was neutral, and then the obtained precipitate was vacuum-dried at 40°C with nitrogen for 24 hours to obtain two Viti 3 C 2 Nano powder;

[0035] Then weigh 1g of two-dimensional Ti 3 C 2 The powder was dispersed in 100 mL of water, and the aqueous dispersion of the two-dimensional Ti3C2 powder wa...

Embodiment 3

[0038] Firstly, 1 g of LiF was added to 60 mL of hydrochloric acid solution with a concentration of 9 mol / L contained in a polytetrafluoroethylene beaker at room temperature, and the LiF was fully dissolved after continuous magnetic stirring for 15 min, and then 1 g of Ti 3 AlC 2 Slowly add the powder into the above solution for 30 minutes, heat up to 45°C and react for 48 hours. After the reaction, the mixture is washed with deionized water and centrifuged at 3500 rpm for 5 minutes. Repeat the cleaning and centrifugation for 6 times. The supernatant after each centrifugation was discarded as a waste liquid, and fresh deionized water was added until the pH value of the supernatant was neutral, and then the obtained precipitate was vacuum-dried at 25 ° C for 48 h with nitrogen to obtain two Viti 3 C 2 Nano powder;

[0039] Then weigh 2g of two-dimensional Ti 3 C 2 The powder was dispersed in 100 mL of water, and the aqueous dispersion of the two-dimensional Ti3C2 powder wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com