Epigallocatechin gallate microcapsule powder and preparation method thereof

A technology of epigallocatechin and gallate, applied in the field of epigallocatechin gallate microcapsule powder and preparation thereof, can solve the problems of affecting EGCG activity, reducing bioavailability, pain and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

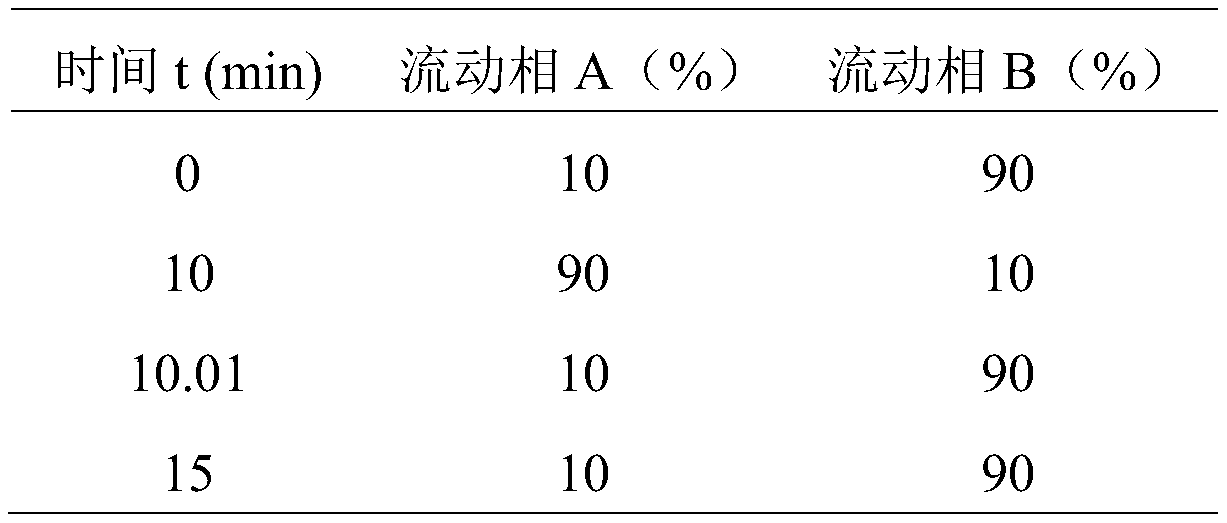

[0029] More specifically, the above-mentioned EGCG microcapsule powder preparation method comprises the following steps:

[0030] ① Prepare the raw materials epigallocatechin gallate, hydroxypropyl methylcellulose, ascorbic acid, microcrystalline cellulose and hydrogenated palm oil so that the mass ratio is 10~40:8:10~40:20~80: 15;

[0031] ② Mix and stir hydroxypropyl methylcellulose and water according to the mass ratio of 1:50 until completely dissolved to obtain slurry I;

[0032] ③Mix epigallocatechin gallate (EGCG), microcrystalline cellulose, ascorbic acid and slurry I, and granulate in a high-shear granulator at a stirring speed of 2000rpm, a cutter speed of 2500rpm, granulate for 2min, flow After melting and drying, it is made into Granule II;

[0033] ④ Use hydrogenated palm oil as the embedding agent to coat the granule II, the material temperature is 45°C, and the air volume is 35m 3 / h, embedding for about 30min to prepare epigallocatechin gallate microcapsule ...

Embodiment 1

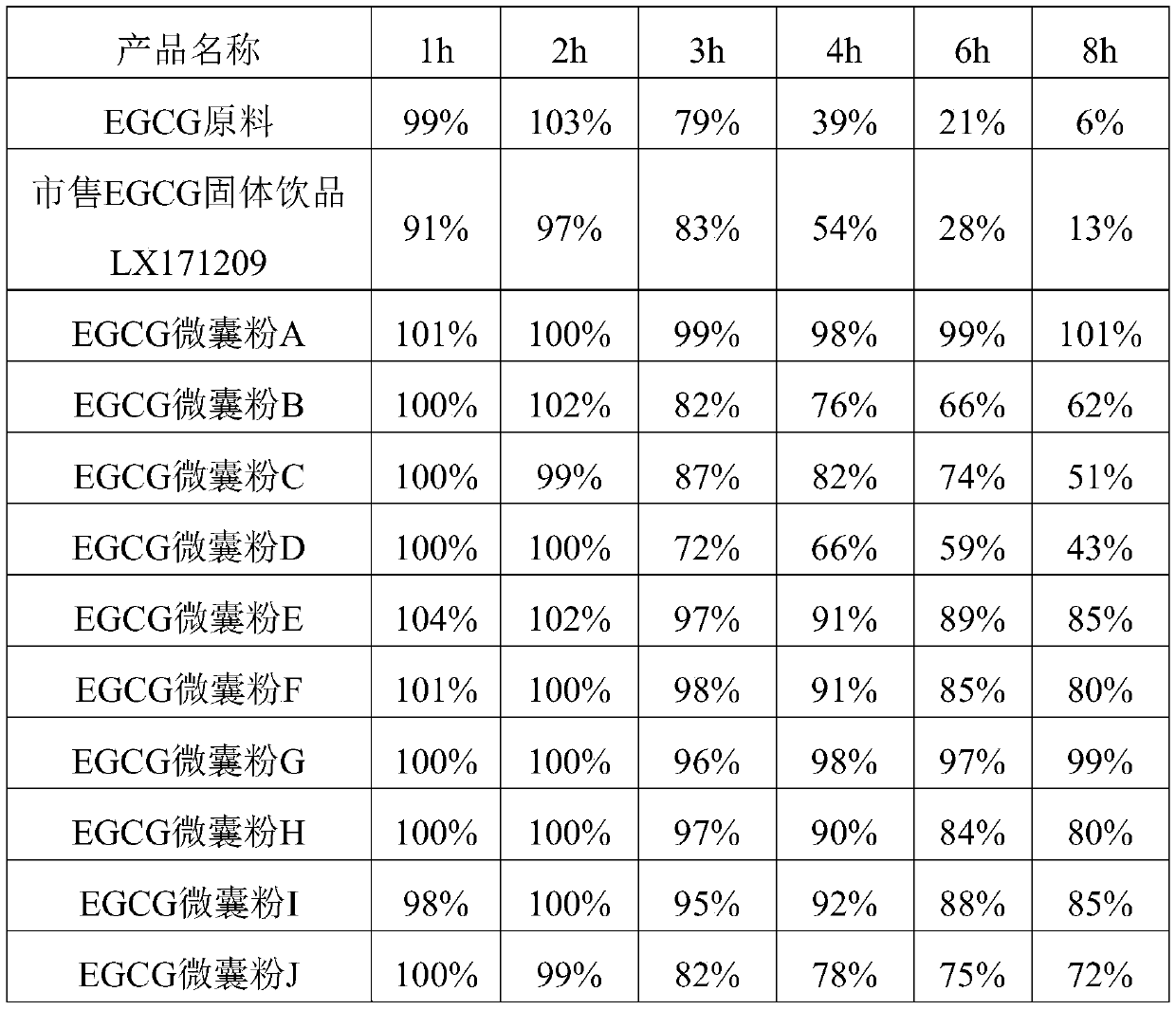

[0040] Embodiment 1: EGCG microcapsule powder A and evaluation thereof

[0041] (1) 660g of microcrystalline cellulose and 16g of hydroxypropyl methylcellulose (viscosity 15mpa.s) were dropped into 800ml water to be prepared into a uniform emulsion; 170g of EGCG raw material powder and 170g of ascorbic acid raw material were weighed and mixed and stirred evenly to prepare mixture Ia;

[0042] (2) Pour the mixture Ia into a high-shear granulator for granulation, with a stirring speed of 2000rpm, a cutter speed of 2500rpm, and 2min. Use a 30-mesh sieve to make granules and place them in a fluidized bed at an inlet temperature of 55 ℃, air volume 35m 3 / h heating for about 1h to obtain EGCG semi-finished particles Sa.

[0043] (3) EGCG semi-finished granules Sa are placed in a fluidized bed, the material temperature is 45°C, and the air volume is 35m 3 / h, using hydrogenated palm oil to embed for about 30min to obtain EGCG microcapsule powder A.

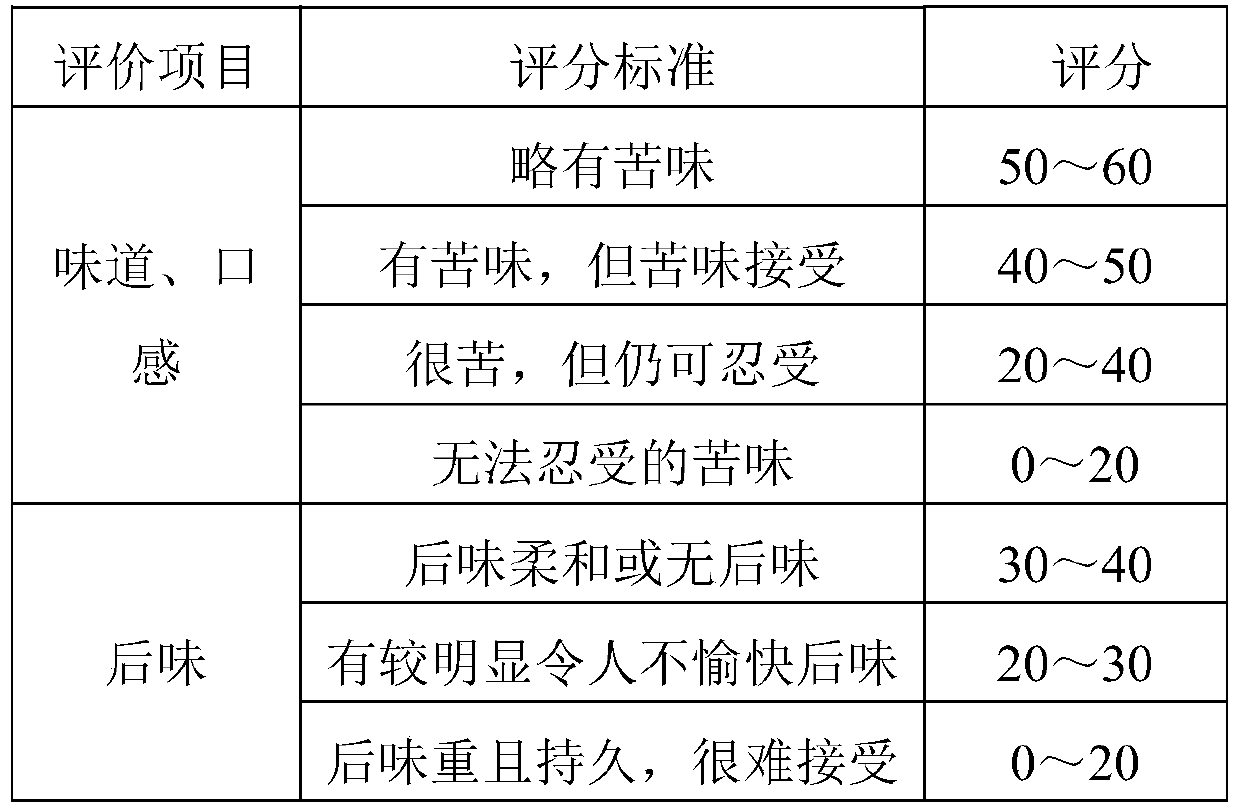

[0044] The EGCG microcapsule ...

Embodiment 2

[0046] Embodiment 2: EGCG microcapsule powder B and its evaluation

[0047] (1) 745g of microcrystalline cellulose and 16g of hydroxypropyl methylcellulose (viscosity 15mpa.s) are dropped into 800ml water to be mixed with a uniform emulsion, and 170g of EGCG raw material powder and 85g of ascorbic acid raw material are mixed and stirred evenly, and prepared as mixture 1b ;

[0048] (2) The mixture Ib is poured into a high-shear granulator for granulation, the stirring speed is 2000rpm, the cutter speed is 2500rpm, 2min, and the EGCG particles are made by 30 mesh sieve granulation and placed in a fluidized bed with an inlet air temperature of 55 ℃, air volume 35m3 / h heat drying for about 1h to obtain EGCG semi-finished particles Sb.

[0049] (3) EGCG semi-finished granules Sb are placed in a fluidized bed with a material temperature of 45°C and an air volume of 35m3 / h, and are embedded in hydrogenated palm oil for about 30 minutes to obtain EGCG microcapsule powder B;

[0050...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com