Preparation method of high-purity porous spherical silica gel filler

A porous spherical, silica gel technology, applied in the field of silica gel adsorption packing, can solve the problems of low bonding efficiency, small active points or catalytic points, and it is difficult to avoid the interference of metal impurities, and achieves the effect of good regularity and good chromatographic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

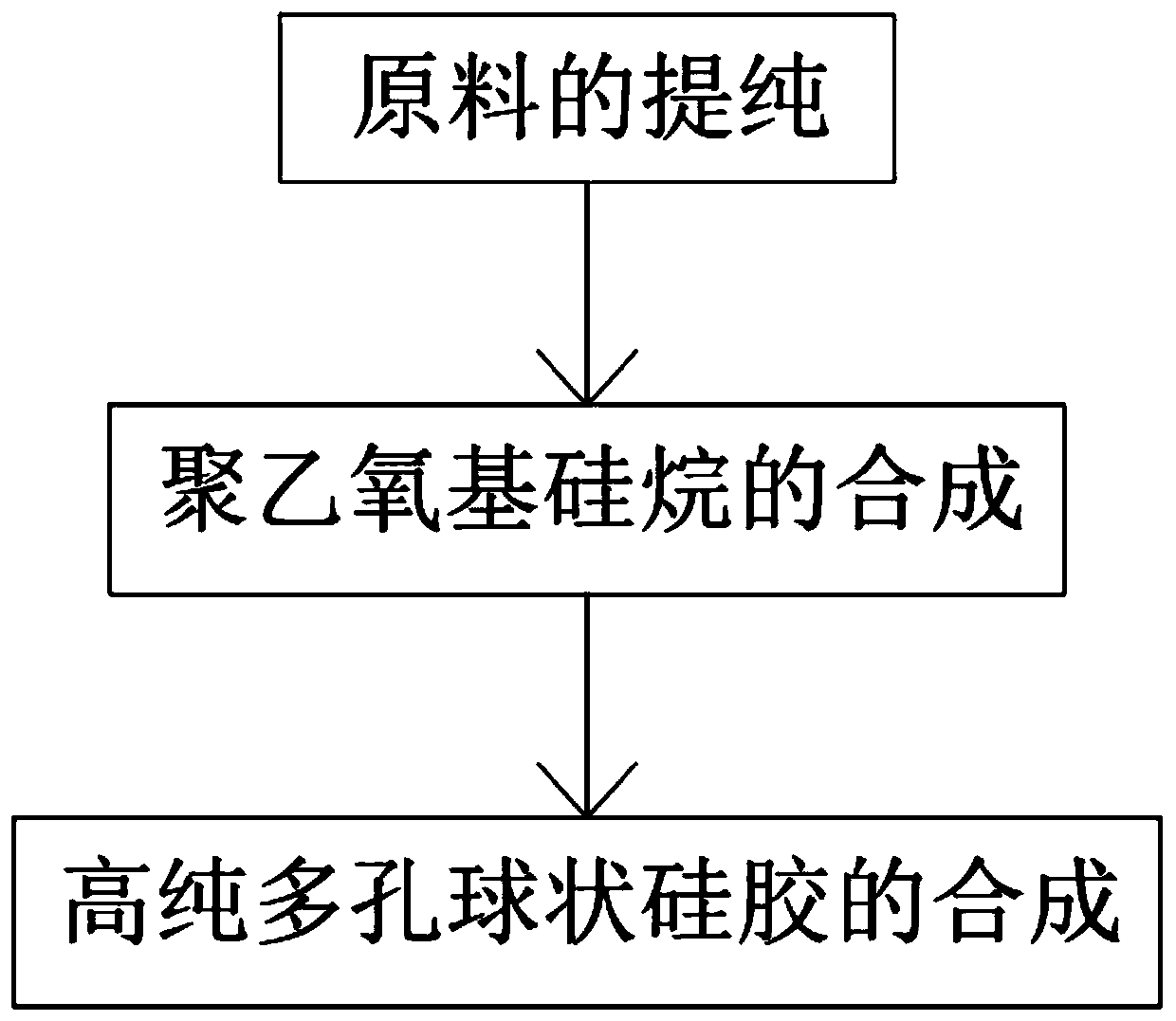

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of high-purity porous spherical silica gel filler, comprising the following preparation steps:

[0024] Step 1: Purify tetraethoxysilane by distillation under reduced pressure, and then collect it in a clean and dry ground container for later use;

[0025] Step 2: Weigh the purified tetraethoxysilane obtained in step 1, add it to a three-necked flask, add absolute ethanol according to the mass ratio of tetraethoxysilane: absolute ethanol = 1:1.5, and put it at 30°C Stir for 40min, the stirring speed is 350r / min;

[0026] Step 3, add 1.0% stabilizer cyclohexane, 2.0% catalyst hexamethylenetetramine, and 3.0% porogen to the above system in turn, keep the stirring speed constant, stir for 60 minutes, and slowly heat up to 120 ℃, then pass nitrogen to protect, continue to stir and react for 24h to obtain the product after reaction; the porogen is a mixture of polyethylene glycol 400 and sorbitan monooleate with a molar ratio of 2:1, and the The poroge...

Embodiment 2

[0032] A preparation method of high-purity porous spherical silica gel filler, comprising the following preparation steps:

[0033] Step 1: Purify tetraethoxysilane by distillation under reduced pressure, and then collect it in a clean and dry ground container for later use;

[0034] Step 2: Weigh the purified tetraethoxysilane obtained in step 1, add it to a three-necked flask, add absolute ethanol according to the mass ratio of tetraethoxysilane: absolute ethanol = 1:1.5, and put it at 30°C Stir for 40min, the stirring speed is 300r / min;

[0035] Step 3, adding 0.5% stabilizer 2-methylpentane, 1.8% catalyst N,N-dimethylcyclohexylamine, and 2.0% porogen to the above system in sequence, keeping the stirring speed constant, Stir for 60 minutes, slowly raise the temperature to 120°C, then pass nitrogen for protection, continue to stir and react for 24 hours, and obtain the product after the reaction; the porogen is polyethylene glycol 400 and sorbitan monooleate with a molar ra...

Embodiment 3

[0041]A preparation method of high-purity porous spherical silica gel filler, comprising the following preparation steps:

[0042] Step 1: Purify tetraethoxysilane by distillation under reduced pressure, and then collect it in a clean and dry ground container for later use;

[0043] Step 2: Weigh the purified tetraethoxysilane obtained in step 1, add it to a three-necked flask, add absolute ethanol according to the mass ratio of tetraethoxysilane: absolute ethanol = 1:1.5, and put it at 30°C Stir for 40min, the stirring speed is 400r / min;

[0044] Step 3: Add the stabilizer cyclopropane with a molar concentration of 1.5%, 2.3% catalyst N,N-dimethylbenzylamine, and 4.0% porogen to the above system in sequence, keep the stirring speed constant, stir for 60 minutes, and slowly heat up to 120° C., and then pass nitrogen for protection, and continue to stir and react for 24 hours to obtain the reacted product; the porogen is a mixture of polyethylene glycol 400 and sorbitan monool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com