GaN-based multi-quantum-well laser epitaxial wafer with low V-type defect density and preparation method thereof

A technology of defect density and multiple quantum wells, which is applied in GaN-based multi-quantum well laser epitaxial wafers and preparation fields with low V-type defect density, can solve problems such as increasing device threshold characteristics, deteriorating thermal stability of quantum wells, and device failure , to reduce the possible path of impurity migration, improve the uniformity of In composition, improve the life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

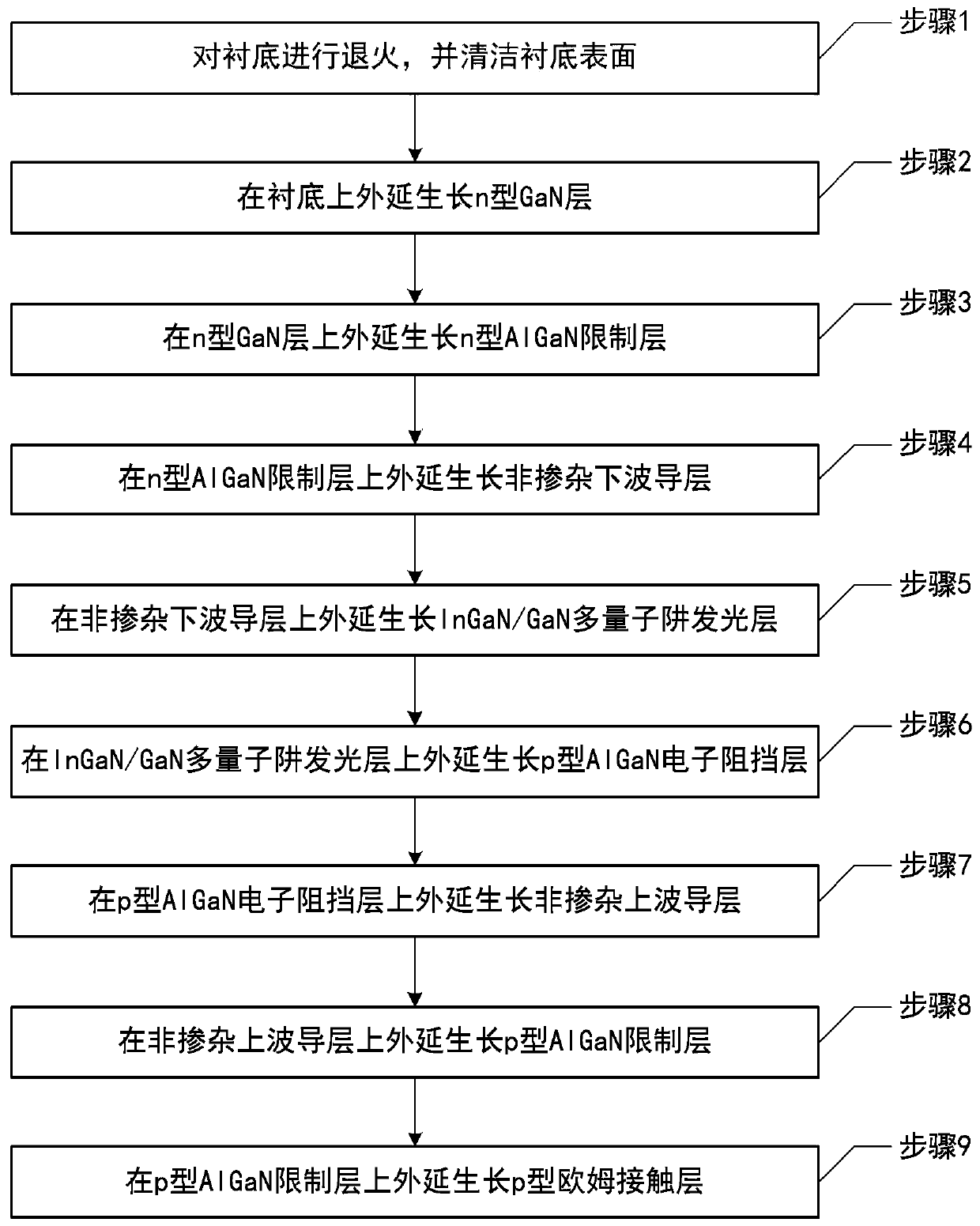

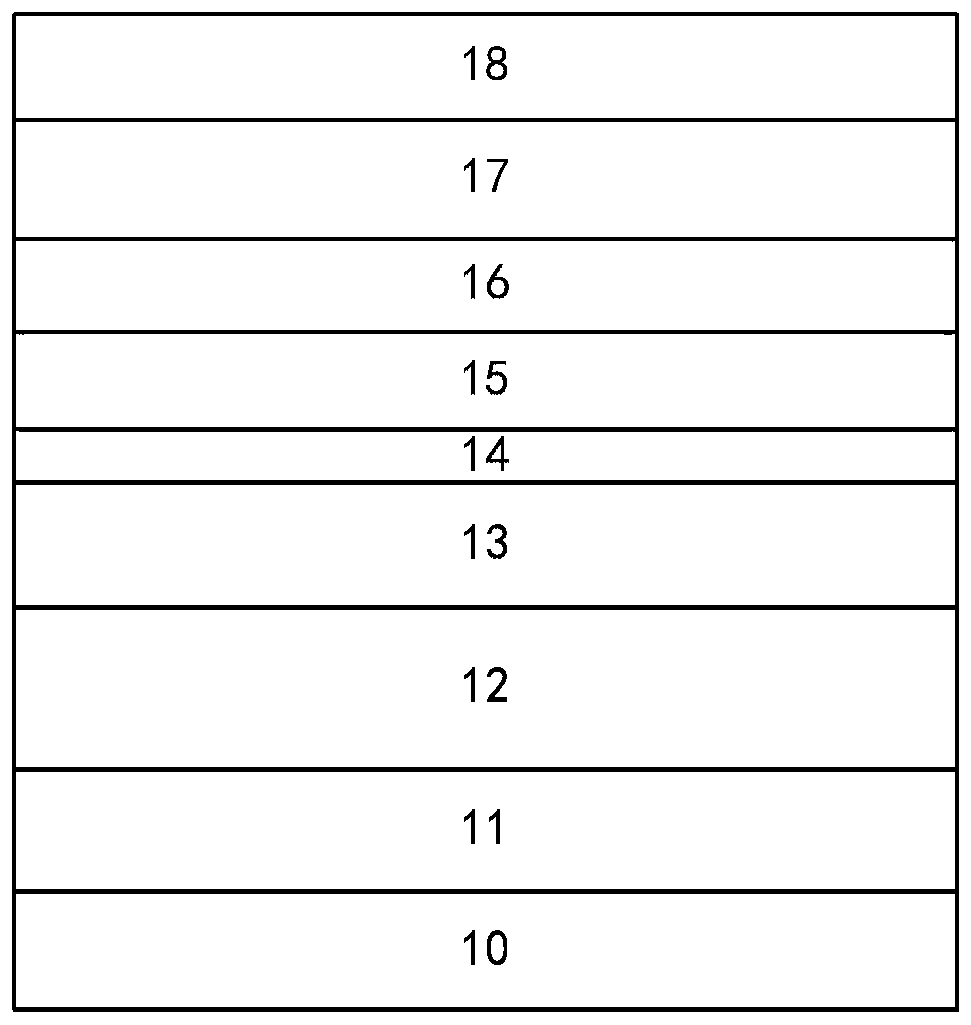

[0032] figure 1 A flow chart of a method for manufacturing a GaN-based multi-quantum well laser epitaxial wafer with low V-type defect density provided by an embodiment of the present disclosure is schematically shown. figure 2 A schematic diagram of the structure of a GaN-based multi-quantum well laser epitaxial wafer provided by an embodiment of the present disclosure with a low V-shaped defect density is schematically shown. to combine figure 2 ,right figure 1 Described preparation method is described in detail, and this preparation method comprises:

[0033] Step 1: annealing the substrate 10 and cleaning the surface of the substrate 10 .

[0034] In step 1, the substrate 10 is annealed in a hydrogen atmosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Luminous wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com