A mim injection molding high-end tool, metal powder and preparation method thereof

An injection molding and metal powder technology, which is applied in the direction of mechanical equipment, other manufacturing equipment/tools, engine components, etc., can solve the problems of low hardenability, large tendency of quenching deformation and cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

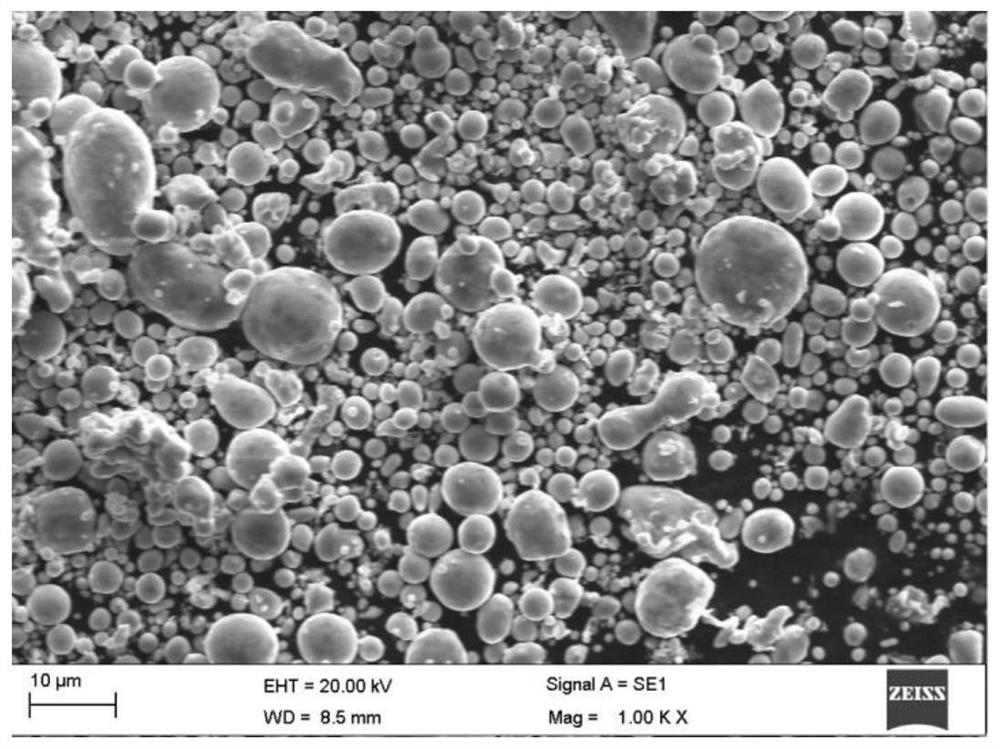

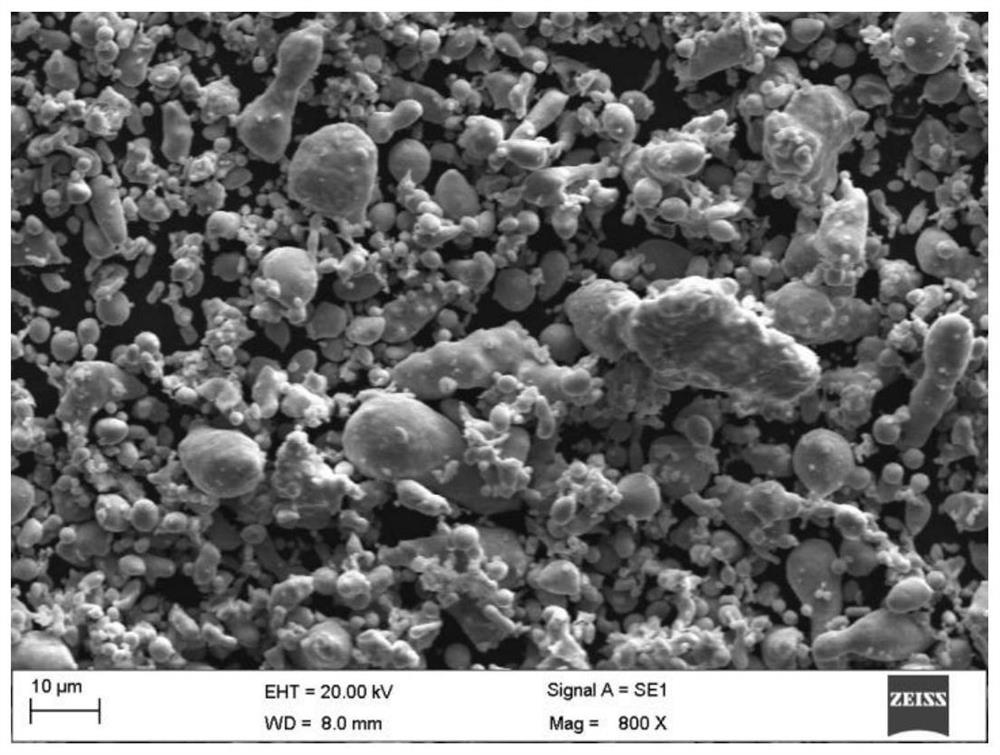

Image

Examples

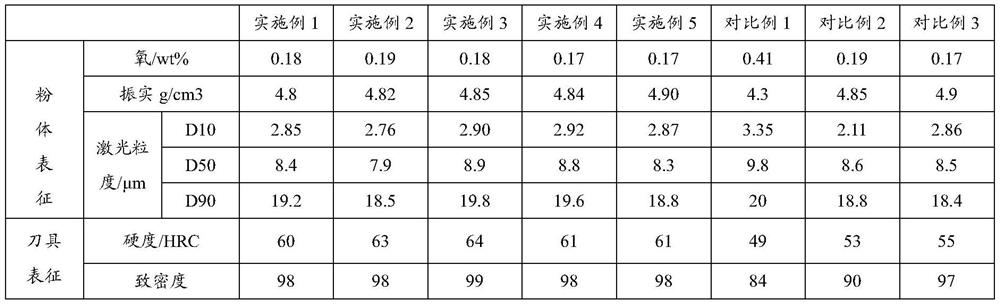

Embodiment 1

[0048] A method for preparing metal powder suitable for MIM injection molding high-end cutting tools, prepared by the following steps:

[0049] (1) Intermediate frequency induction smelting: Feed pure iron, pure copper, ferrochromium, ferromolybdenum, ferrovanadium, ferrotungsten, high-purity silicon, pig iron and tin in sequence, and then smelt in the atmosphere in an intermediate frequency induction furnace. The ratio of the components of the alloy is:

[0050] 75.8wt%Fe-15wt%Cr-2.5wt%Mo-2.0wt%W-1.0wt%V-1.5wt%Cu-0.5wt%Sn-0.7wt%Si-1.0wt%C; the above ingredients are mass percent ;During the smelting process, the smelting power is controlled to be 100-500KW, and the smelting time is 50.0-55.0 minutes. After the molten steel temperature reaches 1650-1700℃, alloying treatment is carried out. The alloying time is 15 minutes, and then the power is reduced to 100- 150KW, use silicon calcium and lime to deoxidize the molten steel by slagging, and clean the slag, start the pump to po...

Embodiment 2

[0056] The difference between this Example 2 and Example 1 is that the composition of a metal powder suitable for MIM injection molding high-end cutting tools prepared in this Example 2 is adjusted, and the alloy composition of the prepared alloy powder is as follows:

[0057] 74.1wt%Fe-16wt%Cr-2.5wt%Mo-2.0wt%W-1.5wt%V-1.5wt%Cu-0.5wt%Sn-0.7wt%Si-1.2wt%C, the above ingredients are mass percent .

Embodiment 3

[0059] The difference between this Example 3 and Example 1 is that the composition of a metal powder suitable for MIM injection molding high-end cutting tools prepared in this Example 3 is adjusted, and the alloy composition of the prepared alloy powder is as follows:

[0060] 72.4wt%Fe-15wt%Cr-4.0wt%Mo-2.0wt%W-2.0wt%V-1.5wt%Cu-1.0wt%Sn-0.7wt%Si-1.4wt%C, the above ingredients are mass percent .

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser granularity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com