Rare earth doped sesquioxide submicron X ray imaging monocrystalline film scintillation screen, and preparation method thereof

A sesquioxide and single crystal thin film technology, which is applied in the field of single crystal thin film scintillation screens for submicron X-ray imaging, can solve problems such as low luminous efficiency, solvent impurity pollution, and difficulty in preparing single crystal thin films, and achieve optical properties and Blink high performance, high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0048] Implementation Case 1: (Lu 0.9 Eu 0.1 ) 2 o 3 / YSZ(100) flashing screen

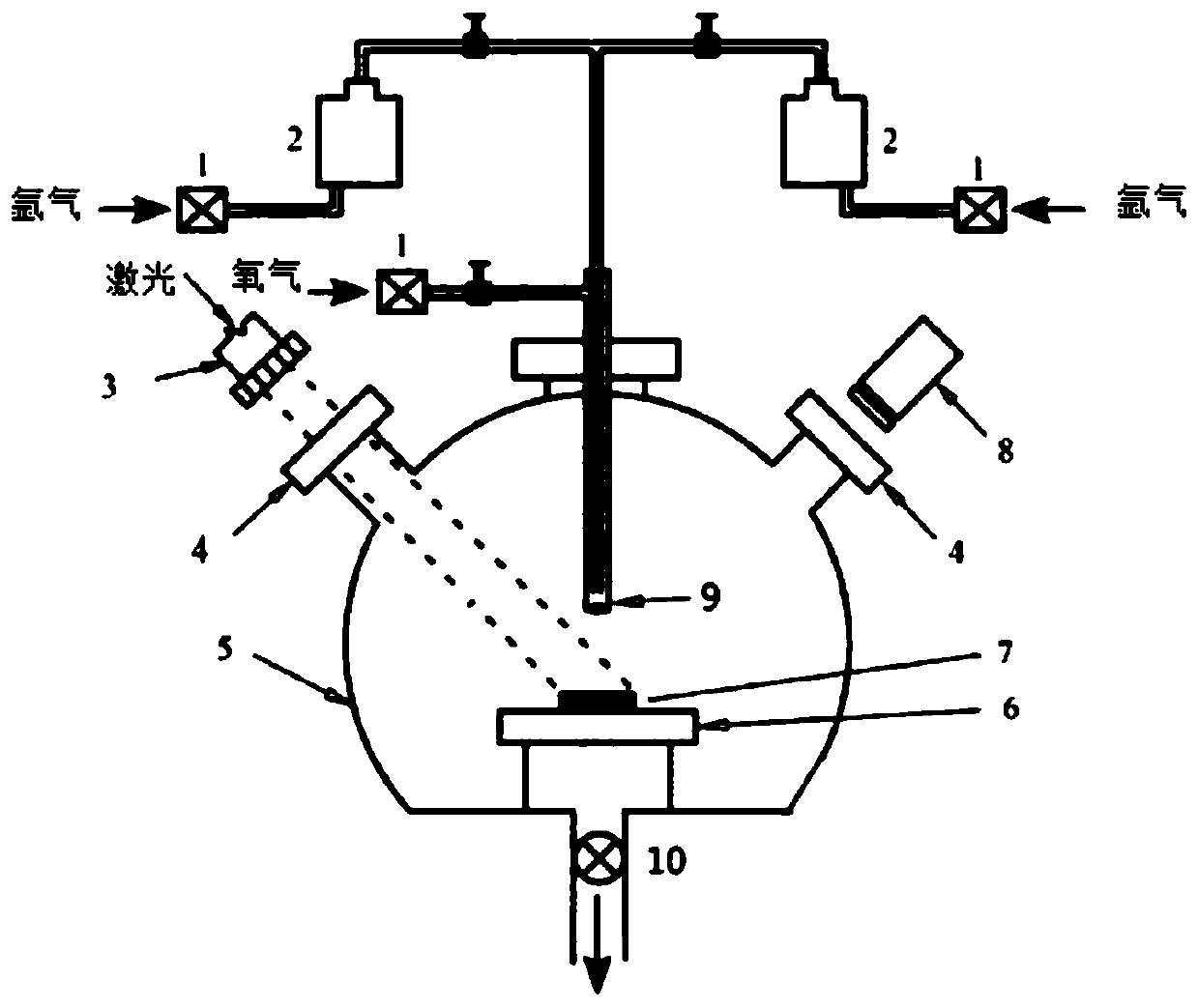

[0049] Such as figure 1 As shown, the selected laser-enhanced chemical vapor deposition is as follows figure 1 device shown. According to above-mentioned preparation process in raw material tank 2 organic matter is pressed (Lu (dpm) 3 : Eu(dpm) 3 =90at%: 10at%) to weigh the ingredients, a total of 1g, after mixing evenly, pour into the tank source and put into the raw material tank 2. A YSZ (100) single crystal substrate having a size of 10 x 10 x 0.5 mm was placed on the substrate 7 . The substrate 7 is then placed on the sample stage 6, which is adjusted to be under the laser light. The CVD chamber 5 is vacuumed with a vacuum pump 10 . The substrate 7 is heated to 1100° C., and the heating rate of the substrate 7 cannot exceed 10° C. / min. When the substrate 7 exceeds 400°C, the heating of the nozzle 9 and the input pipe is started. When the substrate 7 exceeds 900°C, the raw material...

Embodiment example 2

[0050] Implementation case 2: (Y 0.9 Tb 0.1 ) 2 o 3 / Y 2 o 3 (100) flash screen

[0051] Such as figure 1 As shown, the organic matter is in accordance with (Y(dpm) 3 : Tb(dpm) 3 =90at%: 10at%) carry out weighing batching, altogether 1.5g, pour into tank source after mixing evenly and put into raw material tank 2. Put a Y of size 10 x 10 x 0.5mm 2 o 3 A (100) single crystal substrate is placed on the substrate 7 . The substrate 7 is then placed on the sample stage 6, which is adjusted to be under the laser light. The CVD chamber 5 is vacuumed with a vacuum pump 10 . The substrate 7 is heated to 1100° C., and the heating rate of the substrate 7 cannot exceed 10° C. / min. When the substrate 7 exceeds 400° C., the nozzle 9 and the input pipeline are heated. When the substrate 7 exceeds 900°C, the raw material tank 2 is heated, and the temperature of the raw material tank 2 is set to 190°C. The temperature of the nozzle 9 and the input pipeline is about 50° C. higher...

Embodiment example 3

[0052] Implementation case 3: (Lu 0.95 PR 0.05 ) 2 o 3 / YSZ(100) flashing screen

[0053] Such as figure 1 As shown, the organic matter is divided according to (Lu(dpm) 3 : Pr(dpm) 3 =95at%: 5at%) carry out weighing batching, totally 2g, pour into tank source after mixing evenly and put into raw material tank 2. A YSZ (100) single crystal substrate having a size of 10 x 10 x 0.5 mm was placed on the substrate 7 . The substrate 7 is then placed on the sample stage 6, which is adjusted to be under the laser light. The CVD chamber 5 is vacuumed with a vacuum pump 10 . The substrate 7 is heated to 1100° C., and the heating rate of the substrate 7 cannot exceed 10° C. / min. When the substrate 7 exceeds 400° C., the nozzle 9 and the input pipeline are heated. When the substrate 7 exceeds 900°C, the raw material tank 2 is heated, and the temperature of the raw material tank 2 is set to 200°C. The temperature of the nozzle 9 and the input pipeline is about 50° C. higher than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com