Preparation method of nano conductive composite film

A composite film and nano-conductive technology, which is applied in the manufacture of cables/conductors, conductive layers on insulating carriers, circuits, etc., can solve the problems of poor processability, application restrictions, and low mechanical properties of conjugated conductive polymers, and achieve high transparency. , good mechanical properties, increase the effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

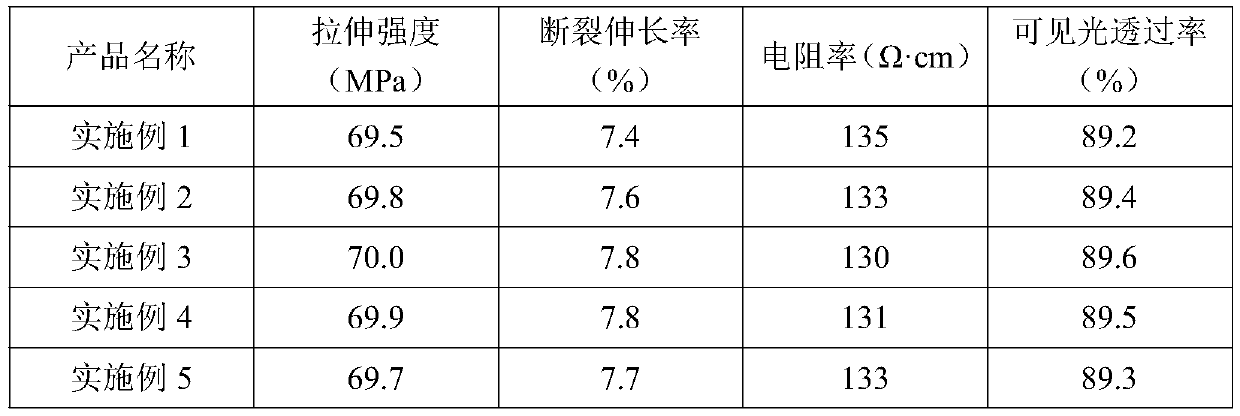

Examples

Embodiment 1

[0033] A preparation method of a nano-conductive composite film, the components are by weight, comprising the following steps:

[0034] (1) Take silk, cut it into 100-200 μm, dip it in silver nitrate solution, adjust the pH of the solution to 3 with hydrochloric acid, and dip it at 30° C. for 1 day;

[0035] (2) Add glucose solution and stir for 10 minutes, let stand for 30 minutes, wherein, the concentration of glucose solution is 5g / L;

[0036] (3) filter, put into vacuum oven, vacuumize and dry;

[0037] (4) Place in a vacuum tube furnace, vacuumize, heat up to 400°C, and keep warm for 2h;

[0038] (5) Naturally cool to room temperature, centrifuge and wash 4 times with absolute ethanol;

[0039] (6) Centrifuge at 2000rpm for 2min, discard the silver particles, and dry;

[0040] (7) evenly spread on the ground electrode in the low-temperature plasma treatment device, and process 10min under the conditions of power frequency 10kHz, working voltage 20kV, and discharge powe...

Embodiment 2

[0050] A preparation method of a nano-conductive composite film, the components are by weight, comprising the following steps:

[0051] (1) Take silk, cut it into 100-200 μm, dip it in silver nitrate solution, adjust the pH of the solution to 3.5 with hydrochloric acid, and dip it at 32°C for 1.5 days;

[0052] (2) Add glucose solution and stir for 15 minutes, let stand for 35 minutes, wherein the concentration of glucose solution is 6g / L;

[0053] (3) filter, put into vacuum oven, vacuumize and dry;

[0054] (4) Place in a vacuum tube furnace, vacuumize, heat up to 420°C, and keep warm for 2h;

[0055] (5) Naturally cool to room temperature, centrifuge and wash 4 times with absolute ethanol;

[0056] (6) Centrifuge at 2050rpm for 2.5min, discard the silver particles, and dry;

[0057] (7) Evenly spread on the ground electrode in the low-temperature plasma treatment device, and process 12min under the conditions of power frequency 12kHz, operating voltage 20kV, and discharg...

Embodiment 3

[0067] A preparation method of a nano-conductive composite film, the components are by weight, comprising the following steps:

[0068] (1) Take silk, cut it into 100-200 μm, dip it in silver nitrate solution, adjust the pH of the solution to 3.5 with hydrochloric acid, and dip it at 33° C. for 1.5 days;

[0069] (2) Add glucose solution and stir for 15 minutes, and let it stand for 35 minutes, wherein the concentration of glucose solution is 6.5g / L;

[0070] (3) filter, put into vacuum oven, vacuumize and dry;

[0071] (4) Place in a vacuum tube furnace, evacuate, heat up to 450°C, and keep warm for 2h;

[0072] (5) naturally cool to room temperature, and centrifuge and wash 5 times with absolute ethanol;

[0073] (6) Centrifuge at 2050rpm for 2.5min, discard the silver particles, and dry;

[0074] (7) evenly spread on the ground electrode in the low-temperature plasma processing device, and process 13min under the conditions of power frequency 13kHz, operating voltage 20k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com