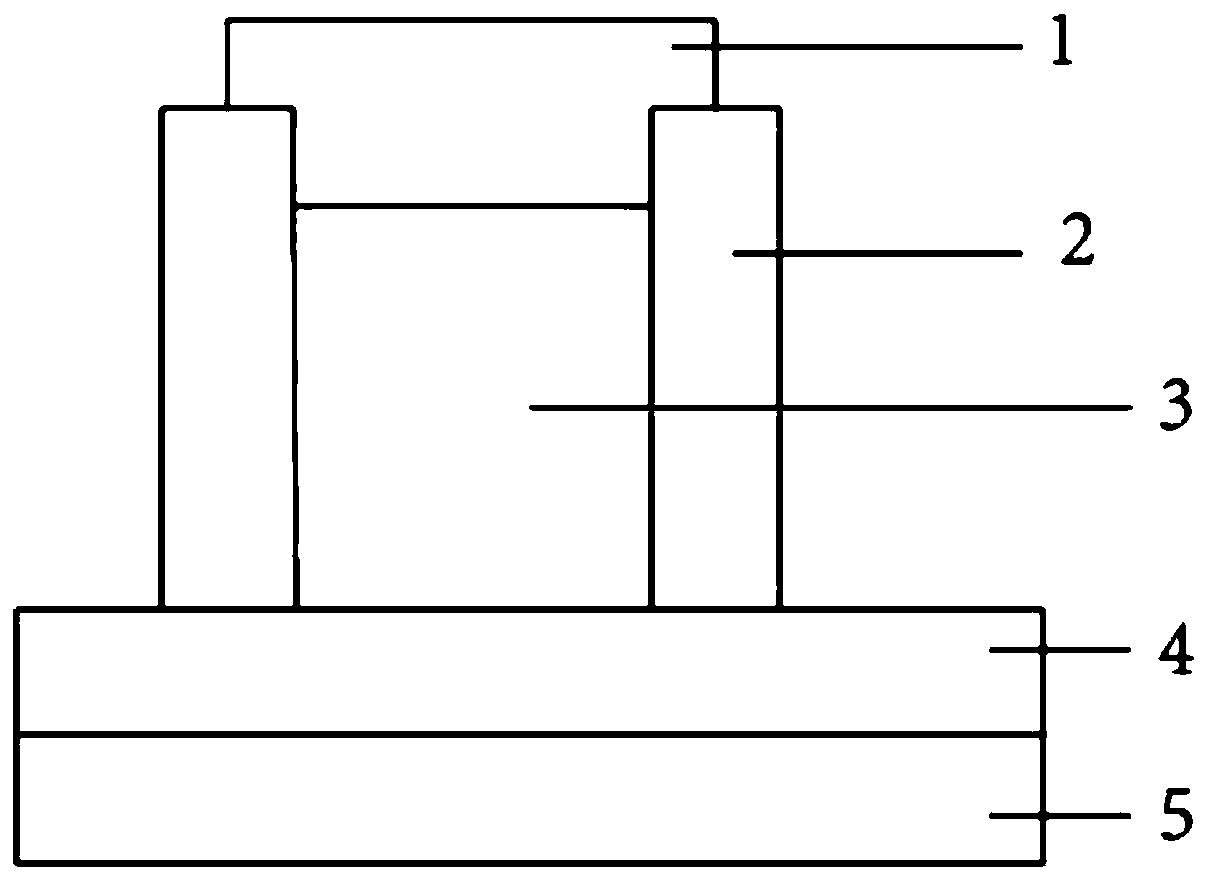

Magnetoresistive sensor structure and manufacturing method thereof

A magnetoresistive sensor and manufacturing method technology, applied in the fields of magnetic field controlled resistors, manufacturing/processing of electromagnetic devices, components of electromagnetic equipment, etc., can solve problems such as difficulty, high cost, and complicated manufacturing process of TMR sensors, Achieve good protection, improve yield, and avoid the effect of removing the residual metal film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

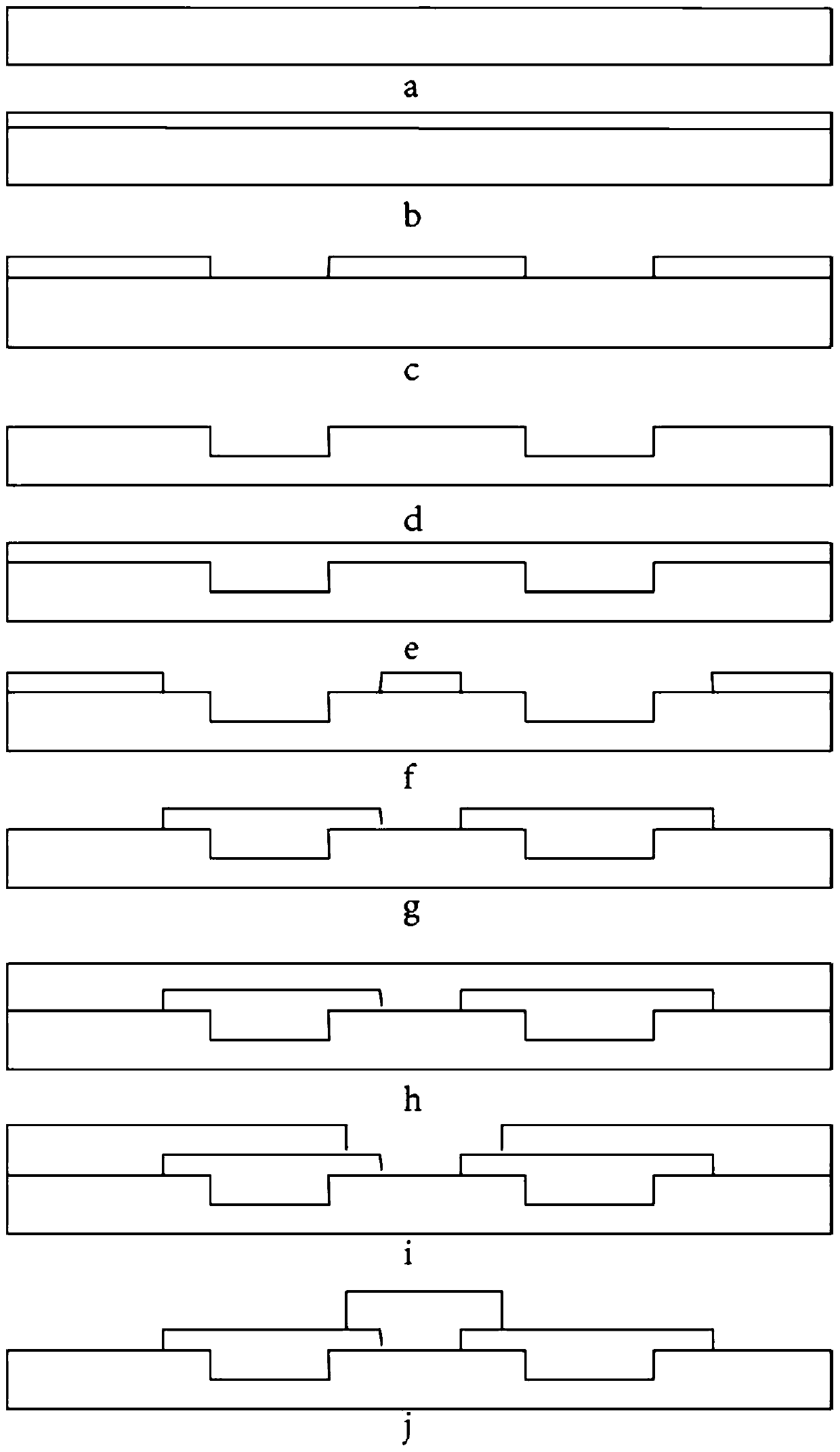

Embodiment 1

[0065] Step 1: Provide a Si substrate, use acetone, alcohol, and deionized water to ultrasonically clean it for 5 minutes, then blow dry it with N2, and keep it in an oven at 115°C for 20 minutes.

[0066] Step 2, the model of the photoresist used in the present invention is APR-3510P. After the photoresist is dropped on the Si substrate, the photoresist is first rotated at a rate of 600 rpm for 10s so that the photoresist covers the Si sheet, and then 4000 rpm Rotate at a rate of 40s to make the photoresist thickness uniform.

[0067] Step 3, put the Si substrate spin-coated with photoresist into an oven, and heat it at 115° C. for 20 minutes, so that the photoresist is completely cured.

[0068] Step 4, exposing the first photoresist layer to ultraviolet light through the mask plate of the first predefined pattern.

[0069] Step 5, develop, remove excess photoresist, and leave a first predefined pattern on the Si substrate.

[0070] Step 6, using magnetron sputtering thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com