Silver nanoparticle coated nitrogen doped porous carbon and preparation method thereof

A technology of nitrogen-doped porous carbon and silver nanoparticles, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of battery short circuit, battery theoretical capacity and low output power, and achieve The effect of increased volume, simple and efficient synthesis steps, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

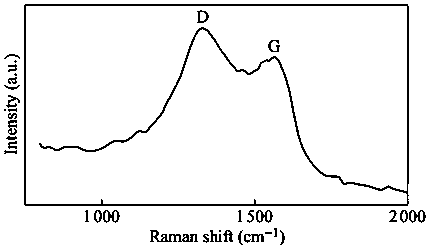

Image

Examples

Embodiment 1

[0025] 1. Synthesis of the precursor ZIF-8: Weigh 0.2 mol of zinc nitrate hexahydrate in a 1000 ml beaker, add 200 ml of anhydrous methanol solution to the beaker, stir at room temperature for 5 min to fully dissolve the zinc nitrate, and prepare Solution A: Weigh 0.8 mol 2-methylimidazole in a 500 ml beaker, add 200 ml of anhydrous methanol solution to the beaker, stir at room temperature for 5 min to fully dissolve 2-methylimidazole; then measure 6.28 ml Pour the 1-methylimidazole solution into the above solution, and stir rapidly to make it fully dispersed in the solution to prepare solution B. Pour solution B into solution A evenly and quickly, stir at room temperature for 5 min to mix the two evenly, seal the mixed solution with plastic wrap, let it stand at room temperature for 12 h, and centrifuge the lower milky liquid for 5 min , and then washed several times with anhydrous methanol, put the product in a ventilated drying oven, and dry at 60 °C for 3 h to obtain ZIF-8...

Embodiment 2

[0030]1. Synthesis of the precursor ZIF-8: Weigh 0.3 mol of zinc nitrate hexahydrate in a 1000 ml beaker, add 300 ml of anhydrous methanol solution to the beaker, stir at room temperature for 8 min to fully dissolve the zinc nitrate, and prepare Solution A: Weigh 1.2 mol 2-methylimidazole in a 500 ml beaker, add 300 ml of anhydrous methanol solution into the beaker, stir at room temperature for 8 min to fully dissolve 2-methylimidazole; then measure 9.42 ml Pour the 1-methylimidazole solution into the above solution, and stir rapidly to make it fully dispersed in the solution to prepare solution B. Pour solution B into solution A evenly and quickly, stir at room temperature for 8 minutes to mix the two evenly, seal the mixed solution with plastic wrap, let it stand at room temperature for 18 hours, and centrifuge the lower milky liquid for 8 minutes , and then washed several times with anhydrous methanol, put the product in a ventilated drying oven, and dry at 70 °C for 4 h to...

Embodiment 3

[0035] 1. Synthesis of the precursor ZIF-8: Weigh 0.4 mol of zinc nitrate hexahydrate in a 1000 ml beaker, add 400 ml of anhydrous methanol solution to the beaker, stir at room temperature for 10 min to fully dissolve the zinc nitrate, and prepare Solution A: Weigh 1.6 mol 2-methylimidazole in a 500 ml beaker, add 400 ml of anhydrous methanol solution to the beaker, stir at room temperature for 10 min to fully dissolve 2-methylimidazole; then measure 12.56 ml Pour the 1-methylimidazole solution into the above solution, and stir rapidly to make it fully dispersed in the solution to prepare solution B. Pour solution B into solution A evenly and quickly, stir at room temperature for 10 min to mix the two evenly, seal the mixed solution with plastic wrap, let it stand at room temperature for 24 h, and centrifuge the lower milky liquid for 10 min , and then washed several times with anhydrous methanol, put the product in a ventilated drying oven, and dry at 80 °C for 5 h to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com