High rate, long cycle and wide temperature range aqueous sodium ion whole battery

A sodium ion, full battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor rate performance, unsatisfactory long cycle, short cycle life, etc., and achieve the effect of high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

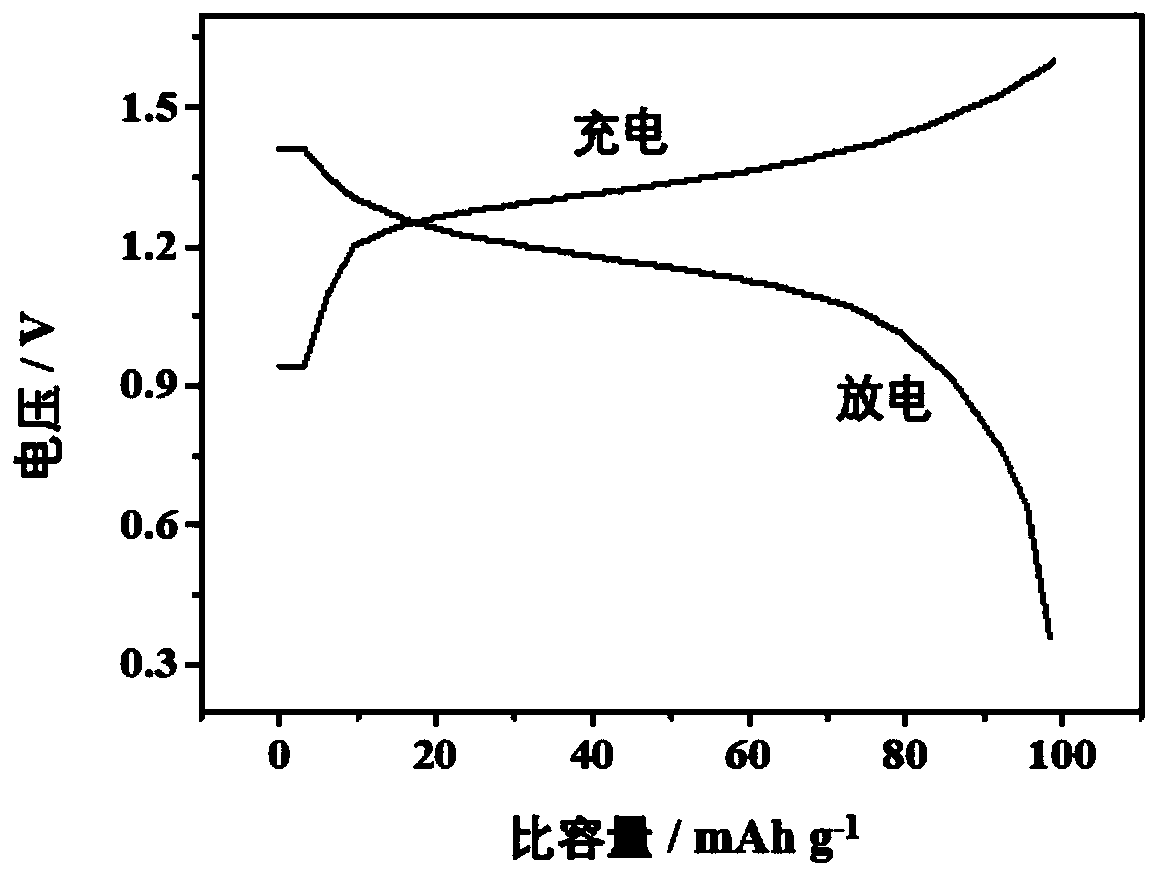

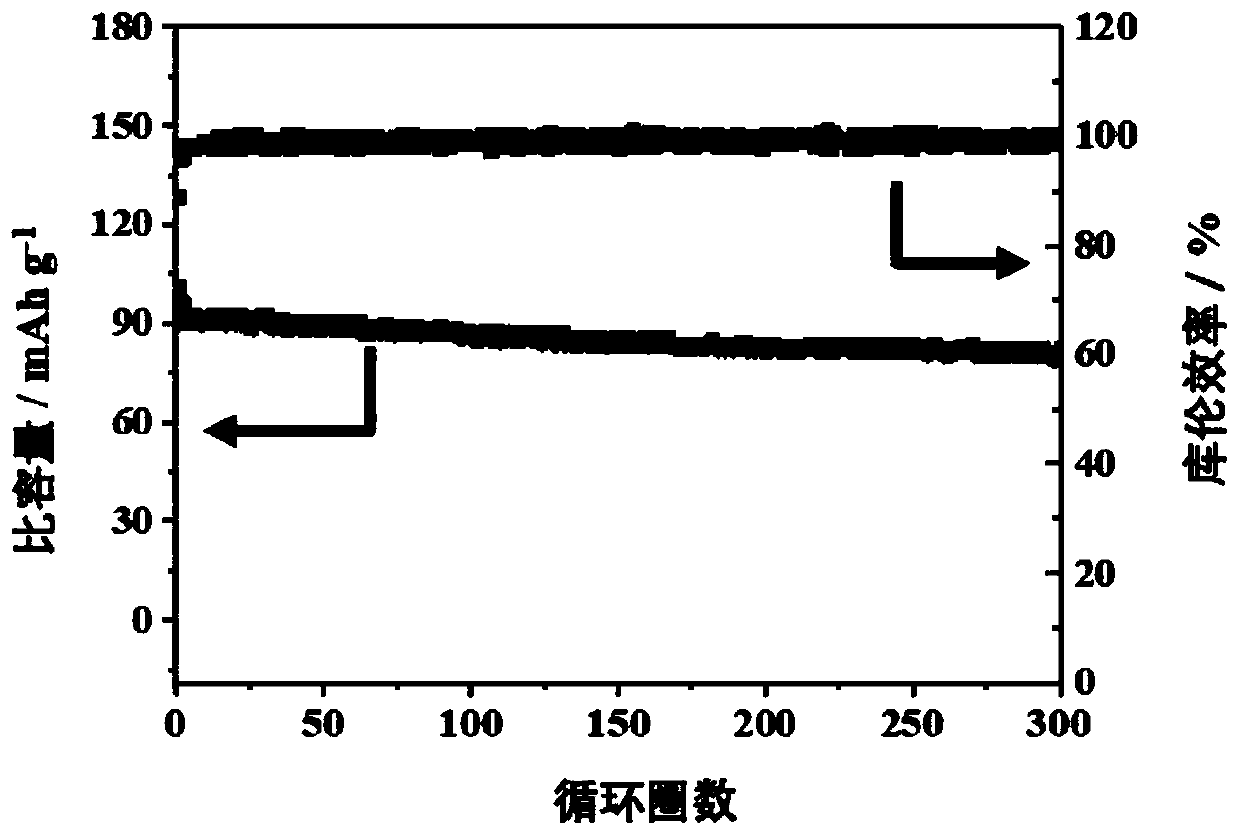

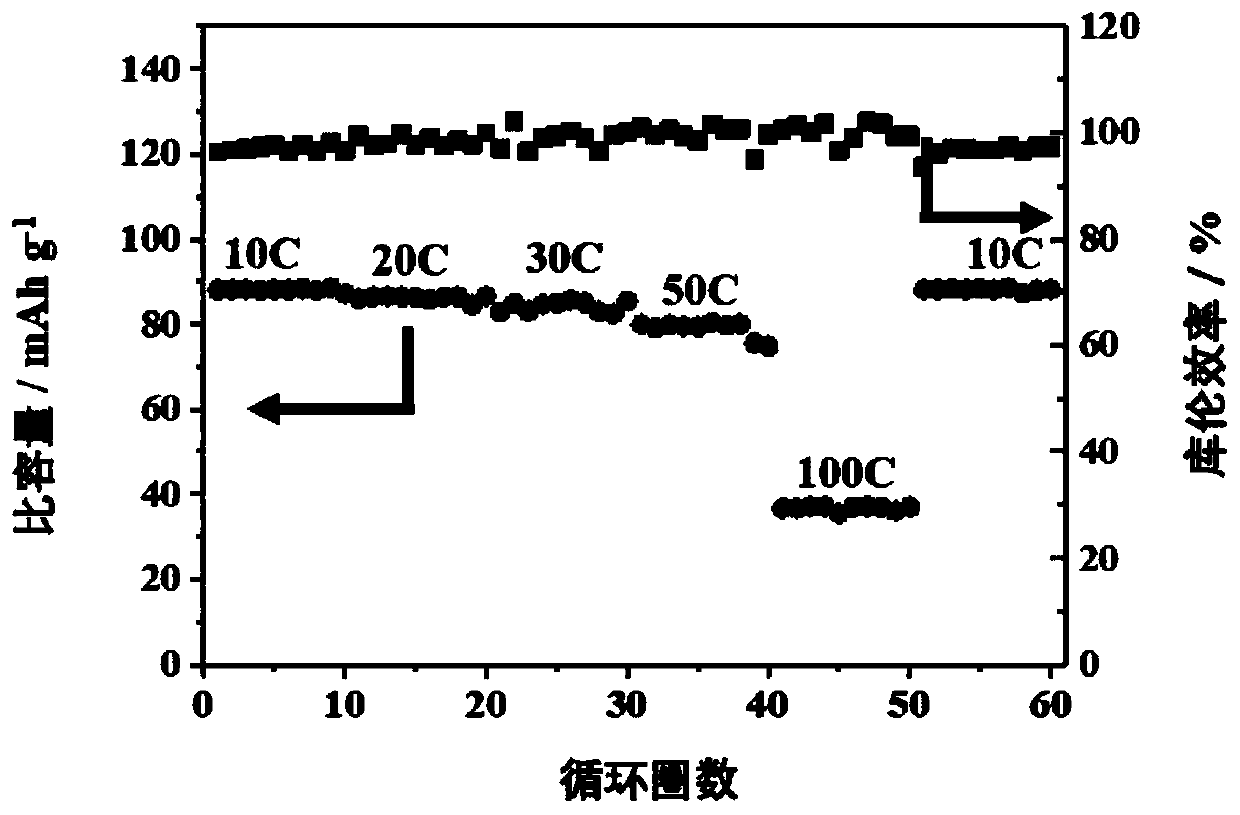

[0023] This embodiment has described a kind of with nickel hydroxide as positive electrode, titanium sodium phosphate as negative electrode, sodium trifluoromethanesulfonate (CF 3 NaO 3 S) Aqueous sodium ion full battery in which the aqueous solution is the electrolyte.

[0024] The positive electrode is a commercial nickel-metal hydride battery as the positive electrode active material, washed with a large amount of deionized water until the solution becomes neutral, and then dried in a vacuum oven at 80°C for 12 hours as the positive electrode.

[0025] Negative electrode gets sodium titanium phosphate as negative electrode active material, conductive carbon black is conductive agent, polyvinylidene fluoride (PVDF) is binding agent, according to active material: conductive carbon: the mass ratio of binding agent=8:1:1, stir Mixed evenly, coated on titanium foil, and then dried in a vacuum oven at 80°C for 12 hours, as a negative electrode.

[0026] The electrolyte configur...

Embodiment 2

[0030] This embodiment has described a kind of with nickel hydroxide as positive pole, sodium titanium phosphate as negative pole, sodium sulfate (Na 2 SO 4 ) Aqueous solution is the aqueous sodium ion full battery of electrolytic solution.

[0031] The preparation of the positive electrode is the same as in Example 1.

[0032] Negative electrode gets titanium sodium phosphate as negative electrode active material, and acetylene black is conductive agent, and polytetrafluoroethylene (PTFE) emulsion is binding agent, according to active material: conductive carbon: the mass ratio of binding agent=8:1:1, stir Mix evenly, roll it into a thin film on a roller press, coat it on a titanium foil, then dry it in a vacuum oven at 100°C for 12 hours, and finally press it on a nickel foam as a negative electrode.

[0033] The electrolyte configuration uses sodium sulfate (Na 2 SO 4 ) is the electrolyte, Na 2 SO 4 The mass ratio to water is 0.14204:1.

[0034] Finally, the positive...

Embodiment 3

[0038] This embodiment has described a kind of with nickel hydroxide as positive pole, sodium vanadium titanium phosphate as negative pole, sodium perchlorate (NaClO 4 ) Aqueous solution is the aqueous sodium ion full battery of electrolytic solution.

[0039] The preparation of the positive electrode is the same as in Example 1.

[0040] Negative electrode gets sodium vanadium titanium phosphate as negative electrode active material, and acetylene black is conductive agent, and polytetrafluoroethylene (PTFE) emulsion is binding agent, according to active material: conductive carbon: the mass ratio of binding agent=8:1:1, Stir and mix evenly, roll it into a thin film on a roller press, coat it on a titanium foil, then dry it in a vacuum oven at 100°C for 12 hours, and finally press it on a titanium mesh as a negative electrode.

[0041] The electrolyte configuration uses sodium perchlorate (NaClO 4 ) as the electrolyte, NaClO 4 The mass ratio to water is 0.24488:1.

[0042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com