A kind of microcapsule and its preparation method and application

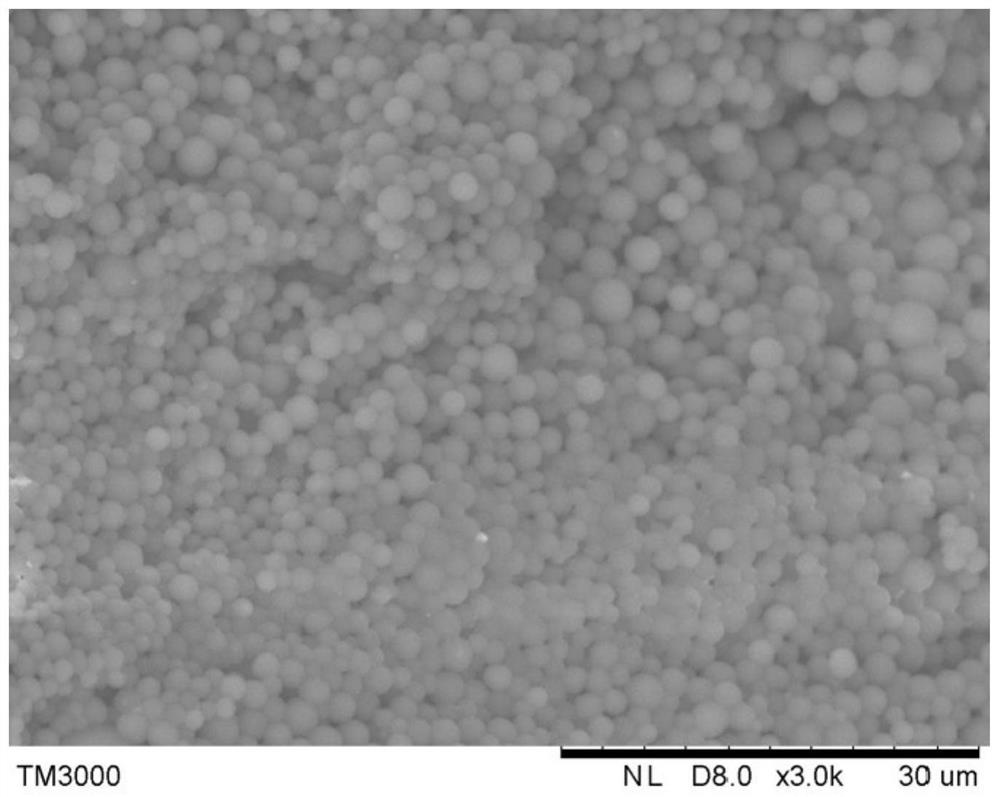

A technology of microcapsules and core materials, which is applied in the field of flavor and fragrance processing, and can solve problems such as uneven distribution, large size of microcapsules, and poor stability of microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A preparation method of microcapsules:

[0062] Step 1. Weigh 1 g of polyvinyl alcohol solid and add it to a 100 ml beaker, add 70 ml of distilled water, place the beaker in a water bath at 30°C, and magnetically stir at a speed of 600 r / min for 5 min to obtain an aqueous emulsifier solution;

[0063] Step 2. Weigh 5g of hexamethylene diisocyanate trimer and 5g of Suyalan essential oil, add them into the emulsifier aqueous solution, add magnetons into the beaker, stir at a speed of 580r / min, and submerge the shearing head into the solution In the process, slowly increase the speed to 4800r / min at a speed of 500r / min per second, cut for 10 minutes, rise to 11000r / min and cut for 8min to obtain an emulsion;

[0064] Step 3. Place the emulsion in a collector-type constant temperature heating magnetic stirrer. When the temperature of the emulsion rises to 75°C, add 2ml of 1,3-butanediol dropwise under the condition of 680r / min. 18μL / s, continue to stir for 1h after the dro...

Embodiment 2

[0067] A preparation method of microcapsules:

[0068] Step 1. Weigh 1.5 g of solid polyvinyl alcohol and add it to a 100 ml beaker, add 70 ml of distilled water, place the beaker in a water bath at 30°C, and magnetically stir at a speed of 600 r / min for 5 min to obtain an emulsifier aqueous solution;

[0069] Step 2. Weigh 4.6g of hexamethylene diisocyanate trimer and 5.5g of rose essential oil, add them to the emulsifier aqueous solution, add magnetons into the beaker, stir at 550r / min, and submerge the shear head into the solution , slowly increase the speed to 5000r / min at a speed of 500r / min per second, cut for 8 minutes, rise to 12000r / min and cut for 7 minutes to obtain an emulsion;

[0070] Step 3. Put the emulsion in a heat-collecting constant temperature heating magnetic stirrer. When the temperature of the emulsion rises to 70°C, add 4.6ml of 1,3-butanediol dropwise under the condition of 650r / min. Acceleration is 20μL / s, continue to stir for 50min after the dropwi...

Embodiment 3

[0073] A preparation method of microcapsules:

[0074] Step 1. Weigh 1.3g of polyvinyl alcohol solid and add it to a 100ml beaker, add 70ml of distilled water, place the beaker in a water bath at 30°C, and magnetically stir at a speed of 600r / min for 5min to obtain an emulsifier aqueous solution;

[0075] Step 2. Weigh 6 g of hexamethylene diisocyanate trimer and 4.8 g of lavender essential oil, add them into the emulsifier aqueous solution, add magnetons in the beaker, and stir at a speed of 600 r / min, and submerge the shearing head in the solution. Slowly increase the speed to 4500r / min at a speed of 500r / min per second, shear for 12 minutes, increase to 10000r / min and shear for 10min to obtain an emulsion;

[0076] Step 3. Place the emulsion in a heat-collecting constant temperature heating magnetic stirrer. When the temperature of the emulsion rises to 80°C, add 2ml of 1,3-butanediol dropwise under the condition of 700r / min. 15μL / s, continue to stir for 70min after the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com