Method for preparing metal/metal oxide composite electrocatalyst

An electrocatalyst and oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of rare precious metal reserves, high price, limited application, etc. problems, to achieve excellent catalytic activity, high controllability, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

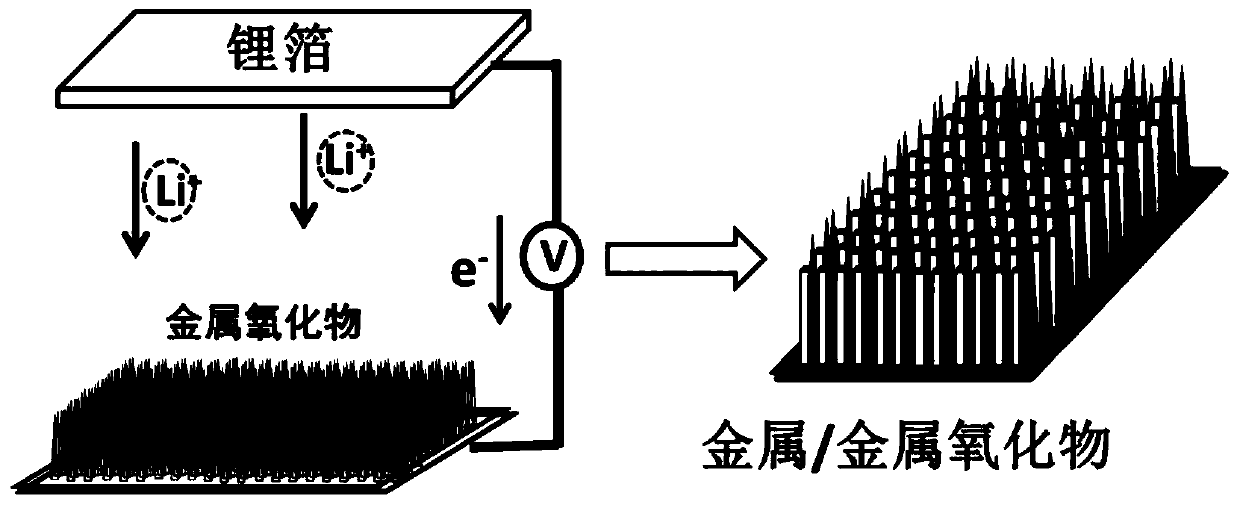

[0029] This embodiment provides a method for preparing metal / metal oxide (NiCo / NiCo 2 o 4 ) method of composite electrocatalyst, specifically:

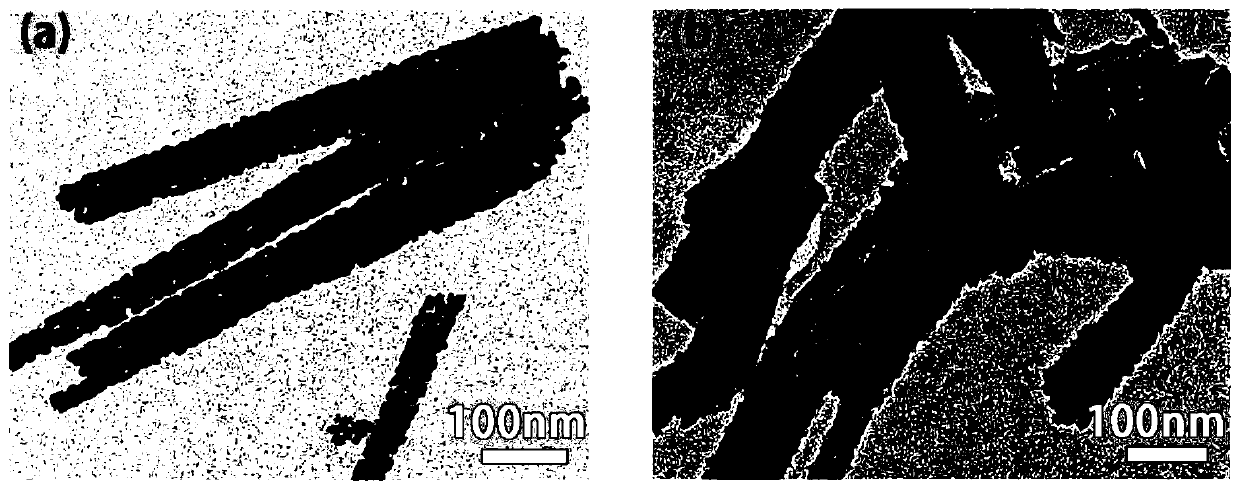

[0030] (a) NiCo growth on carbon paper by hydrothermal method and heat treatment 2 o 4 Materials, specifically: Soak 2×3cm carbon paper in dilute hydrochloric acid for 1 hour, then rinse with deionized water repeatedly, dry for use; weigh 1 mmol NiCl 6 ·6H 2 O, 2 mmol CoCl 2 ·6H 2 O, 2 mmol NH 4 F and 5 mmol urea were dissolved in 60mL deionized water, stirred for 30min, transferred to a 100mL reactor, and put into cleaned carbon paper; the reactor was placed in an oven at 120°C for 6h, and naturally After cooling to room temperature, the NiCo precursor / carbon paper (hydrothermal product) was washed with deionized water, and dried overnight in an oven at 60 °C; the NiCo precursor / carbon paper was heated to 420 °C in air and kept for 2 hours to obtain NiCo 2 o 4 / carbon paper composite material;

[0031] (b) A two-electrode...

Embodiment 2

[0035] This embodiment provides a method for preparing NiCo / NiCo 2 o4 The specific steps of the composite electrocatalyst method are basically the same as those in Example 1, except that in step (b), the charging and discharging current is 3 mA, the cycle is 1 cycle, and the charging and discharging voltage ranges from 0.5 to 2.8 V. The obtained material has excellent oxygen evolution ability under alkaline conditions, at 10 mA / cm -2 The overpotential at the current density is 303 mV.

Embodiment 3

[0037] This embodiment provides a method for preparing NiCo / NiCo 2 o 4 The specific steps of the composite electrocatalyst method are basically the same as those in Example 1, except that in step (b), the charging and discharging current is 5 mA, the cycle is 1 cycle, and the charging and discharging voltage ranges from 0.8 to 2.8 V. The obtained material has excellent oxygen evolution ability under alkaline conditions, at 10 mA / cm -2 The overpotential at the current density is 350 mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com