Method for removing chlorine and heavy metals in incineration fly ash with organic mixed garbage fermentation liquid

A technology for incinerating fly ash and fermentation liquid, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve the problems of limited industrial application, high price of pure acid, etc., to save water, High economic benefit, important effect of environmental benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Preparation of lactic acid fermentation broth:

[0023] (1) Activation of strains: Take the cryotube containing Enterococcus faecium stored at -70°C out of the refrigerator and place it in a water bath at about 38°C immediately, until all the ice inside the cryotube is dissolved. The bacterial solution was inserted into the sterilized MRS liquid medium at the inoculation ratio of 10%, and was incubated at a constant temperature of 150 r / min at 37° C. for 24 hours to complete the activation.

[0024] (2) Preparation of seed solution: take a certain amount of activated bacterial solution and insert it into a new MRS liquid medium at an inoculation ratio of 10% (w / w), and cultivate at a constant temperature of 150 r / min and 37 ° C for 12 Hour.

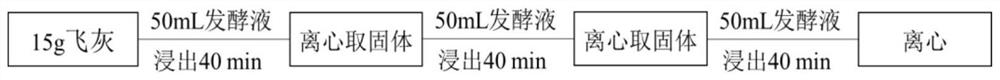

[0025] (3) Lactic acid fermentation: the mixture obtained by mixing organic mixed waste (wet weight) and water in a mass ratio of 1:0-1:2 is the fermentation substrate, inoculated with 2%-15% (w / w) Enterococcus faecium seed liqui...

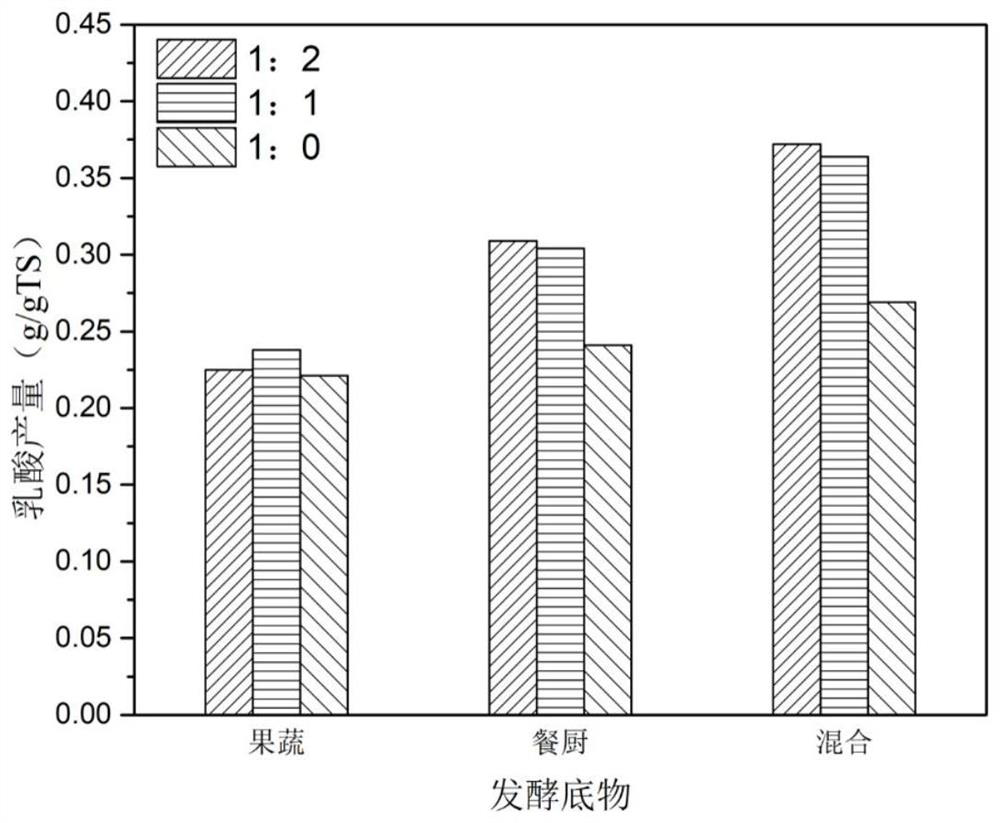

Embodiment 1

[0028] The production of lactic acid in the process of single fermentation and mixed fermentation of kitchen waste and fruit and vegetable waste was investigated. The fermentation process is as described above, and the fermentation substrates are divided into 9 types: ①Food waste (wet weight): water=1:2 (w / w) ②Food waste (wet weight): water=1:1 (w / w) ③ Food waste (wet weight): water = 1:0 (w / w) ④ Fruit and vegetable waste (wet weight): water = 1:2 (w / w) ⑤ Fruit and vegetable waste (wet weight): Water = 1: 1 (w / w) ⑥ Fruit and vegetable waste (wet weight): Water = 1: 0 (w / w) ⑦ Organic mixed waste (wet weight): Water = 1: 2 (w / w) ⑧ Organic mixed Garbage (wet weight): water = 1:1 (w / w) ⑨ Organic mixed waste (wet weight): water = 1:0 (w / w), of which organic mixed waste is kitchen waste and fruit and vegetable waste by dry weight The ratio is 1:1 mixed. 10% Enterococcus faecium was inoculated and anaerobic fermentation was carried out at 37°C for 4 days. Unit lactate production (...

Embodiment 2

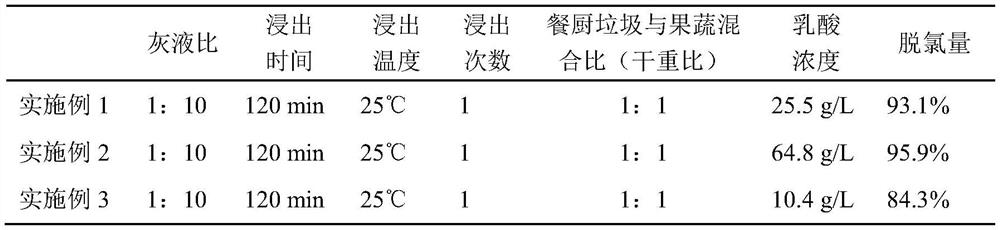

[0033]Get 15g of dried incineration fly ash and place it in a 250mL conical flask, adopt the ratio of ash to liquid to be 1:10, add 150mL of organic mixed garbage lactic acid fermentation broth (the lactic acid concentration in the fermentation broth is 25.5 g / L), then sealed, reacted for 120 min at a temperature of 25° C. and a rotating speed of 150 rpm, and then centrifuged. The chlorine content in the supernatant was determined by ion chromatography, and it was concluded that 93.1% of the chlorine in the fly ash could be leached from the organic mixed waste lactic acid fermentation broth under this condition.

[0034] Examples 2-10 are listed in the following table, and the remaining conditions are the same as those of Example 1.

[0035]

[0036]

[0037] From the comparison between Example 2 and Comparative Example 1, it can be found that, under the same water consumption, using lactic acid fermentation broth to carry out bioleaching of incineration fly ash can grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com