Method and device for co-producing gypsum powder through sulfuric acid production

A sulfuric acid production and gypsum powder technology, which is applied in the field of gypsum building materials, can solve the problems of energy waste, low economic value, and inability to produce, and achieve the effects of eliminating the source of danger of explosion, solving environmental pollution problems, and high heat energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

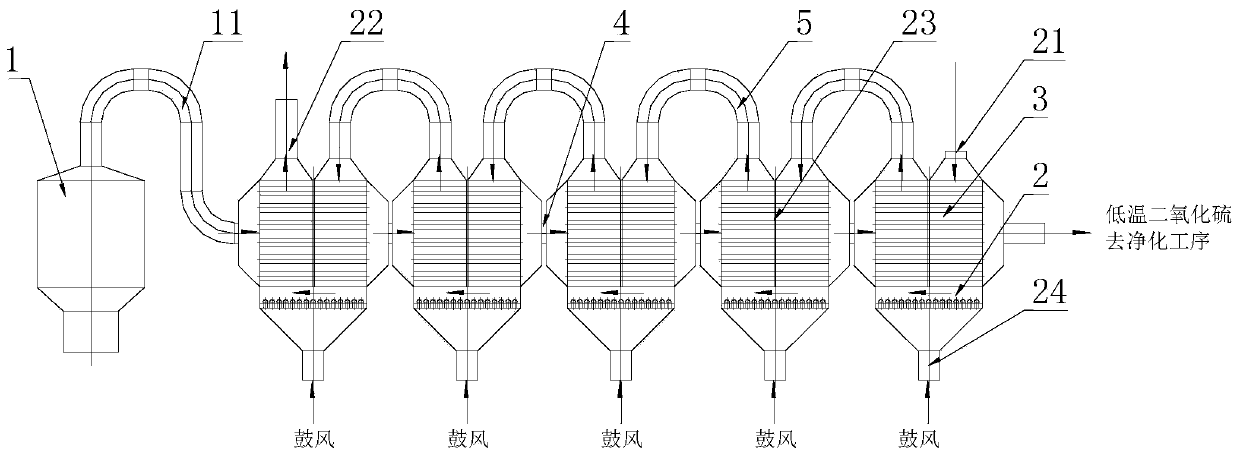

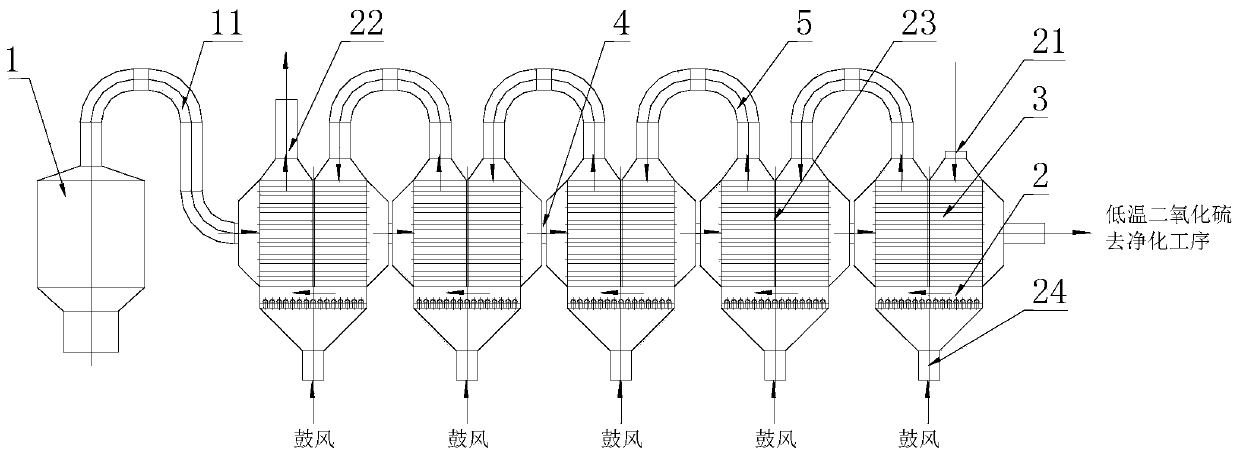

[0032] A method for sulfuric acid production and co-production of gypsum powder, using phosphogypsum as a raw material, high-temperature sulfur dioxide gas produced by sulfuric acid production as a heat source, comprising the following preparation steps:

[0033] (1) Slurry the phosphogypsum, add milk of lime to the phosphogypsum slurry for modification until the pH value of the phosphogypsum slurry is 6, then carry out press filtration, vacuum filtration and centrifuge for the modified phosphogypsum slurry , and finally make the free water content in the filtered modified phosphogypsum less than 25%;

[0034] (2) Add the modified phosphogypsum obtained in the previous step into the fluidized bed, and at the same time, sulfur dioxide gas is introduced into the tube of the tubular heat exchanger, and the air is blown inward from the bottom of the fluidized bed, and the phosphogypsum is discharged from the tubular heat exchanger. Pass through the pipes and perform reverse heat e...

Embodiment 2

[0039] A method for co-producing gypsum powder with sulfuric acid, using phosphogypsum as a raw material, sulfur dioxide gas produced by sulfuric acid production as a heat source, comprising the following preparation steps:

[0040] (1) Slurry the phosphogypsum, add milk of lime to the phosphogypsum slurry for modification until the pH value of the phosphogypsum slurry is 9, then carry out pressure filtration, vacuum filtration and centrifuge for the modified phosphogypsum slurry , and finally make the free water content in the filtered modified phosphogypsum less than 25%;

[0041] (2) Add the modified phosphogypsum obtained in the previous step into the fluidized bed, and at the same time, sulfur dioxide gas is introduced into the tube of the tubular heat exchanger, and the air is blown inward from the bottom of the fluidized bed, and the phosphogypsum is discharged from the tubular heat exchanger. Pass through the tubes and perform reverse heat exchange with sulfur dioxide ...

Embodiment 3

[0046] A method for co-producing gypsum powder with sulfuric acid, using phosphogypsum as a raw material, sulfur dioxide gas produced by sulfuric acid production as a heat source, comprising the following preparation steps:

[0047] (1) Phosphogypsum is slurried, and alkaline industrial waste residue is added to the phosphogypsum slurry for modification until the pH value of the phosphogypsum slurry is 12, and the modified phosphogypsum slurry is successively subjected to pressure filtration, vacuum filtration and Centrifuge, finally make the free water content in the filtered modified phosphogypsum less than 25%;

[0048] (2) Add the modified phosphogypsum obtained in the previous step into the fluidized bed, and at the same time, sulfur dioxide gas is introduced into the tube of the tubular heat exchanger, and the air is blown inward from the bottom of the fluidized bed, and the phosphogypsum is discharged from the tubular heat exchanger. The pipes pass through and perform r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com