Transparent and conductive silk fibroin material and preparation method thereof

A silk fibroin, transparent and conductive technology, applied in photovoltaic power generation, prosthesis, coating, etc., can solve the problem of lack of transparency of regenerated silk fibroin material, and achieve the effect of good conductive network structure, uniform and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for transparent conductive silk fibroin material, the steps are as follows:

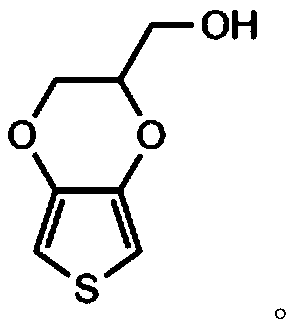

[0047] (1) Add SDS in the aqueous solution of EDOT-OH whose concentration is 30mmol / L, obtain the EDOT-OH aqueous solution containing SDS colloid, the molar ratio of SDS and EDOT-OH is 0.8:1;

[0048] (2) Carry out insolubilization treatment to silk fibroin material;

[0049] First, silkworm cocoons are boiled and degummed in a sodium carbonate solution with a mass fraction of 0.5%, then dissolved in a 9.0M lithium bromide solution, then dialyzed in deionized water through a regenerated cellulose membrane and concentrated to a concentration of 10wt%, and finally the concentrated solution is cast After being drip-coated on a polydimethylsiloxane (PDMS) substrate and dried to form a thin film, soaked in an 80% ethanol aqueous solution to promote the transformation of the secondary structure of the product to a β-sheet to generate a water-insoluble product, Obtain silk fibroin film afte...

Embodiment 2

[0064] A method for transparent conductive silk fibroin material, the steps are as follows:

[0065] (1) Add SDS to the aqueous solution of EDOT-OH with a concentration of 30mmol / L to obtain an aqueous solution of EDOT-OH containing SDS colloid, and the molar ratio of SDS to EDOT-OH is 0.6:1;

[0066] (2) Carry out insolubilization treatment to silk fibroin material;

[0067]First, silkworm cocoons are boiled and degummed in a sodium carbonate solution with a mass fraction of 0.5%, then dissolved in a 9.0M lithium bromide solution, then dialyzed in deionized water through a regenerated cellulose membrane and concentrated to a concentration of 20wt%, and finally the concentrated solution is cast. After being drip-coated onto the plane and the PDMS substrate with raised microchannel patterns and dried to form a thin film, a layer of silk fibroin solution is coated on both sides and pressed together, and heat-treated at 70°C for 18 hours to obtain the insolubilization treatment ...

Embodiment 3

[0076] A method for transparent conductive silk fibroin material, the steps are as follows:

[0077] (1) Adding SDS in the aqueous solution of EDOT whose concentration is 30mmol / L obtains the EDOT aqueous solution containing SDS colloid, and the molar ratio of SDS and EDOT is 0.4:1;

[0078] (2) Carry out insolubilization treatment to silk fibroin material;

[0079] First, silkworm cocoons are boiled and degummed in a sodium carbonate solution with a mass fraction of 0.5%, then dissolved in a 9.0M lithium bromide solution, then dialyzed in deionized water through a regenerated cellulose membrane and concentrated to a concentration of 15wt%, and finally press the same method as in Example 1 Casting method to obtain silk fibroin film after insolubilization treatment;

[0080] (3) Place the insolubilized silk fibroin film in EDOT aqueous solution containing SDS colloid and vibrate at 20°C for 30 minutes, and the mass / volume ratio of the two is 1 mg / mL;

[0081] (4) adding hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com