Method for treating aluminum silicate solid waste in waste lining of aluminum electrolytic cell

A technology for the waste and treatment of aluminum electrolytic cells, which is applied in the field of solid waste treatment, can solve the problems of incomplete harmless treatment technology, failure to popularize, and difficulty in treatment, and achieve significant economic and social benefits. The effect of harmless treatment and simple treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

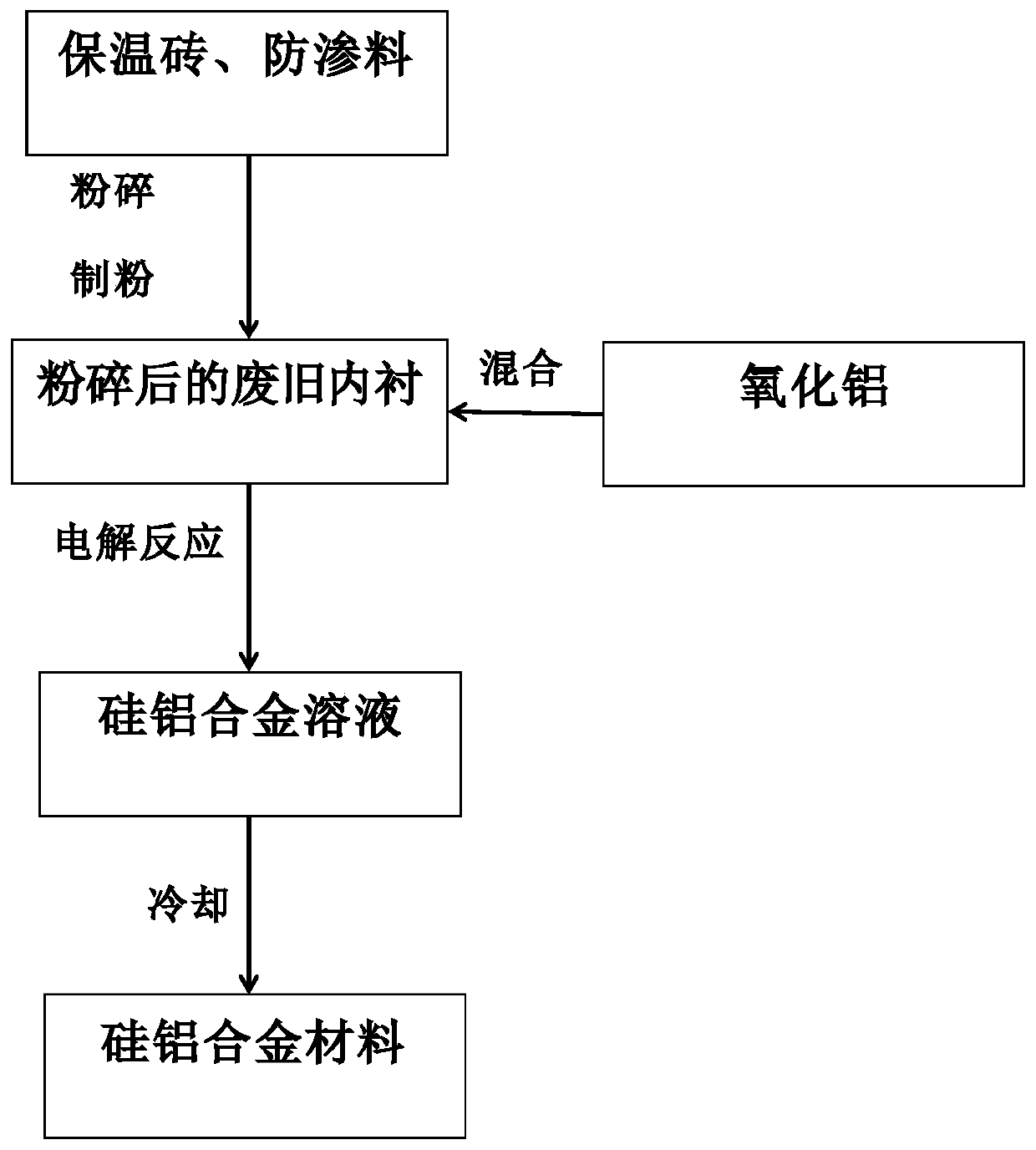

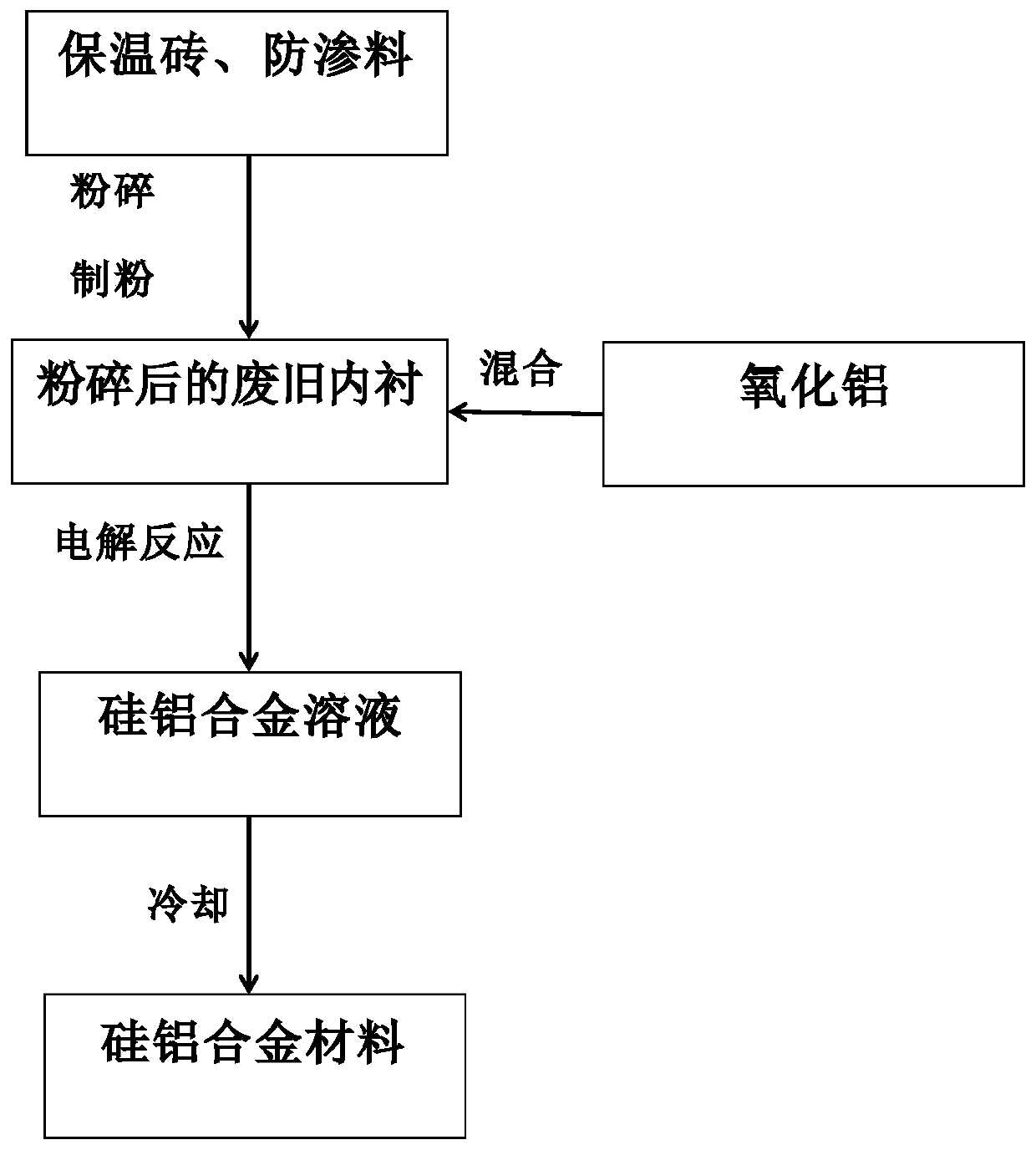

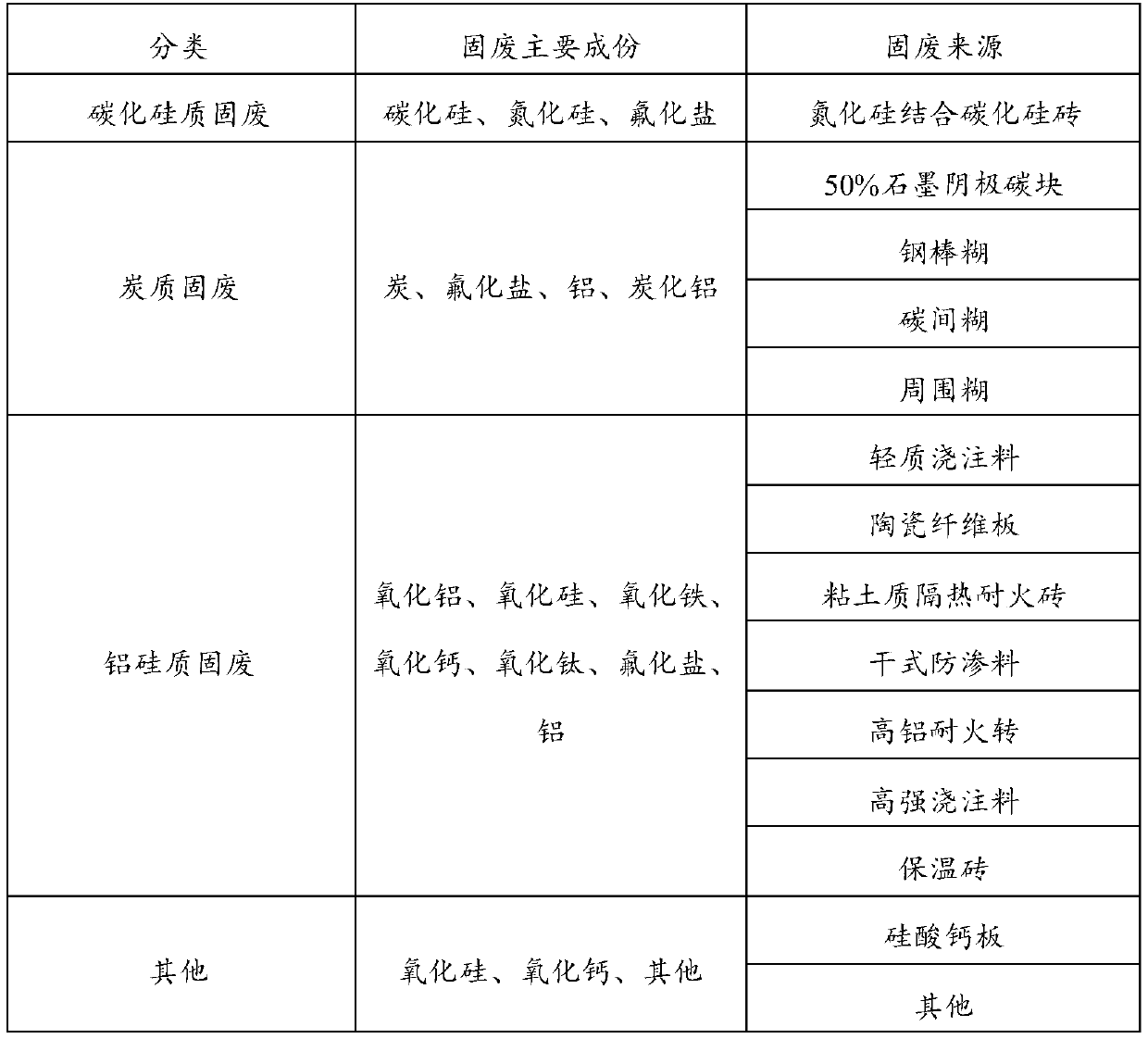

[0048] Choose anti-seepage materials, refractory bricks, and insulation bricks below the cathode carbon block. The aluminum and silicon solid waste in the waste tank liner is crushed and screened to obtain the crushed waste liner with a particle size of 40-200 μm.

[0049] Mix the aluminum and silicon solid waste crushed in the above steps with alumina according to a certain mass ratio, and the specific composition is shown in Table 3 to obtain a mixture.

[0050] Add the mixture into the aluminum electrolytic cell, the dissolution rate of the mixture is slower than that of alumina, and the consumption of fluoride salt will increase, so the parameters of the existing aluminum electrolytic cell need to be adjusted. The initial electrolyte includes 7.072wt% aluminum fluoride, 1.328wt% magnesium fluoride, 2.131wt% lithium fluoride, 2.225wt% potassium fluoride, 2.581wt% alumina, 0.006wt% silica and the balance cryolite . During aluminum-silicon alloy electrolysis, carbon slag an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com