Dual-mode intelligent response laser protection structure and optical detector with the structure

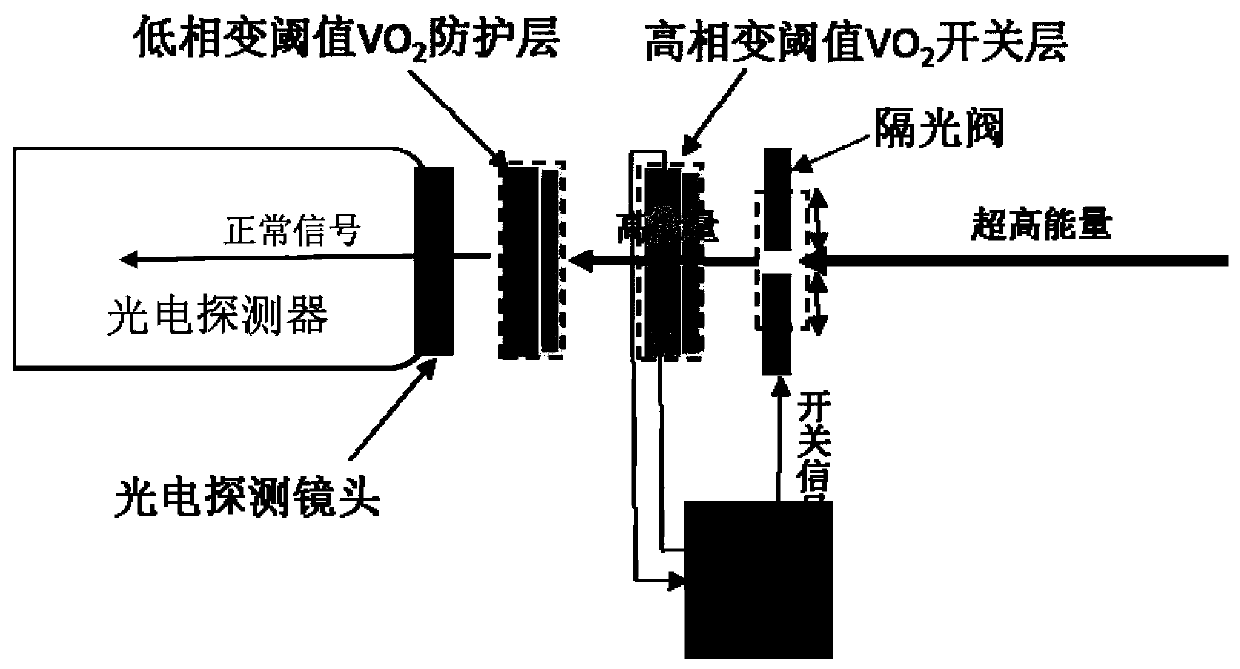

An optical detector and laser protection technology, applied in optics, optical components, instruments, etc., can solve the problem of inability to defend against super-strong lasers, and achieve continuous and effective protection, wide protection spectrum, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Using sapphire as the substrate, the thickness is 0.5mm, polished on both sides, the surface roughness is below 4nm, and the surface is ultrasonically treated in acetone and ethanol for about 10 minutes before coating, and then the surface is blown dry with nitrogen.

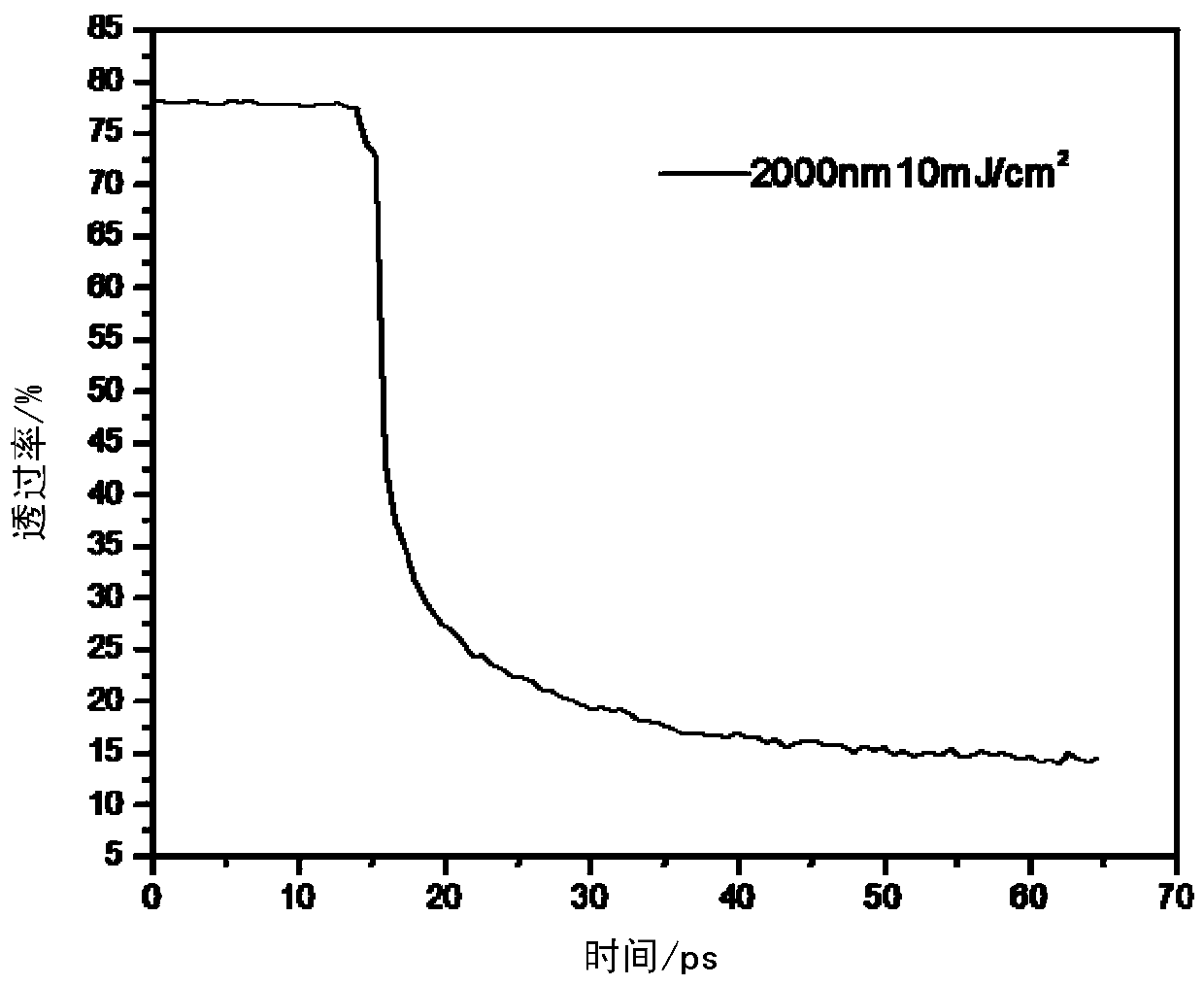

[0062] On the treated substrate, use the magnetron sputtering method to grow the vanadium dioxide thin film layer with low phase change threshold. The specific parameters are: the pre-vacuum degree of the sputtering chamber is -4 Pa, control the flow rate of argon and oxygen at 100sccm and 50sccm respectively, (total flow rate 150sccm), substrate temperature is 500°C, sputtering temperature is 500°C, sputtering pressure is 1.5Pa, sputtering time is 25min, sputtering power is 200W, the target used for sputtering is vanadium trioxide. The prepared low phase transition threshold vanadium dioxide film layer is a layer of pure vanadium dioxide component, brown in color, epitaxial growth along the substrate orie...

Embodiment 2

[0070] The difference with Example 1 is:

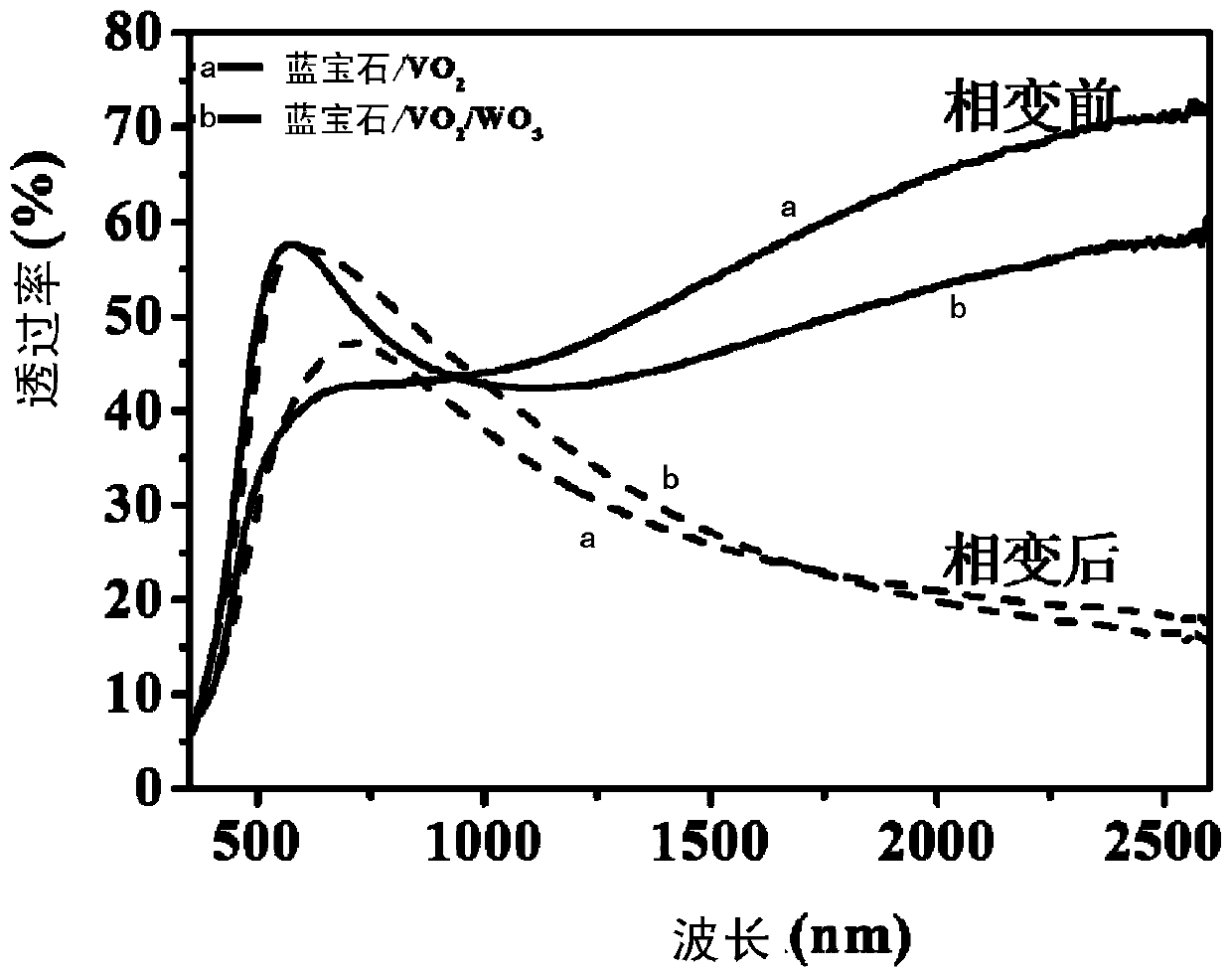

[0071] The anti-reflection layer is further grown in the low phase transition threshold vanadium dioxide thin film layer of embodiment 1, and its material is WO 3 , the magnetron sputtering parameters are: the mixed gas of argon and oxygen is passed into the sputtering deposition chamber, the total gas pressure is controlled at 1.5Pa, the oxygen partial pressure ratio is about 40%, and the intermediate frequency power supply is used, and the power supply current is controlled At 5A, the power is preferably 2.0kw, and high-purity tungsten is used as the sputtering target for sputtering deposition, and the deposition time is 5 minutes. The prepared anti-reflection layer has a thickness of 50nm;

[0072] Further growth anti-reflection layer at the phase change threshold vanadium dioxide thin film layer of embodiment 1, its material is WO 3 , the magnetron sputtering parameters are: the mixed gas of argon and oxygen is passed into the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com