Core-shell anti-ice-freezing modifier, method for producing same, and anti-ice-freezing coating material comprising same

An anti-condensation ice, core-shell type technology, applied in the field of anti-condensation ice coatings and core-shell type anti-condensation ice modifiers, can solve the problems of difficulty in uniform coating on the surface of particles, many voids in the coating material, and huge production workload. Achieve the effects of excellent hydrophobicity, excellent sustained release, and short experimental period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

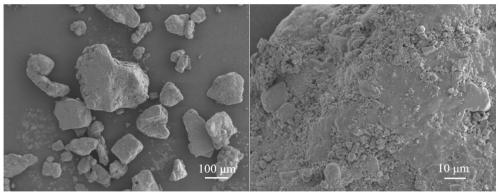

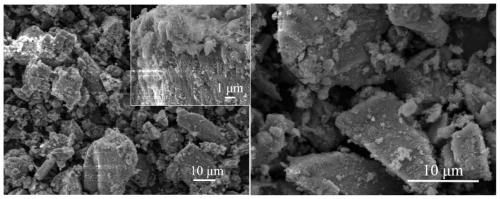

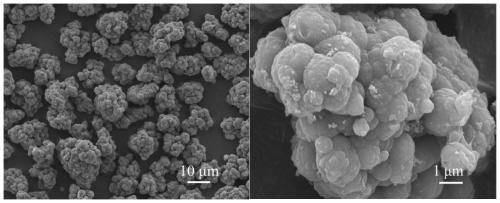

Image

Examples

preparation example Construction

[0059]

[0060] In the step of preparing the pre-dispersion liquid, the water-soluble metal salt is uniformly dispersed in the alcohol solvent, and then a basic catalyst is added thereto, and deionized water is optionally added to obtain the pre-dispersion liquid.

[0061] As the initial dispersion medium, specific examples of the alcohol solvent used in the predispersion liquid include methanol, ethanol, n-propanol, isopropanol, n-butanol, isobutanol, t-butanol, n-pentanol, neopentyl alcohol , n-hexanol, cyclopentanol, cyclohexanol, benzyl alcohol, phenylethyl alcohol, ethylene glycol. These can be used alone or in combination of two or more. From the viewpoint of further improving productivity, the alcohol solvent of the present invention is preferably one or more of methanol, ethanol, and isopropanol, more preferably ethanol.

[0062] The details of the water-soluble metal salt particles have been described above and will not be repeated here. From the standpoint of for...

Embodiment 1

[0146] 40 parts of emulsified asphalt with a solid content of 50% was added to 100 parts of a silicone emulsion with a solid content of 50% and stirred at a speed of 200 rpm for 10 minutes, and 16 parts of the core-shell anti-icing modifier prepared in Production Example 2 were added to Stir at a speed of 200 rpm for 15 minutes, add 3 parts of silane coupling agent, and simultaneously add 1.0 parts of dibutyltin dilaurate and stir for 20 minutes at a speed of 300 rpm, and finally add 10 parts of 40-mesh corundum. A hydrophobic slow-release anti-icing silicone coating is obtained.

Embodiment 2

[0148] A silicone coating was obtained in the same manner as in Example 1, except that the core-shell anti-icing modifier in Example 1 was replaced with the core-shell anti-icing modifier prepared in Production Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com