A kind of preparation method of anti-house dust mite allergen der p1, Der f1 spray

A spray and allergen technology, applied in the field of indoor dust mite allergen modification, can solve the problems of slow effect, difficulty in thoroughly cleaning the source of mites, easy repetition, etc., achieve low cost, good anti-allergic effect, and broad application market Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

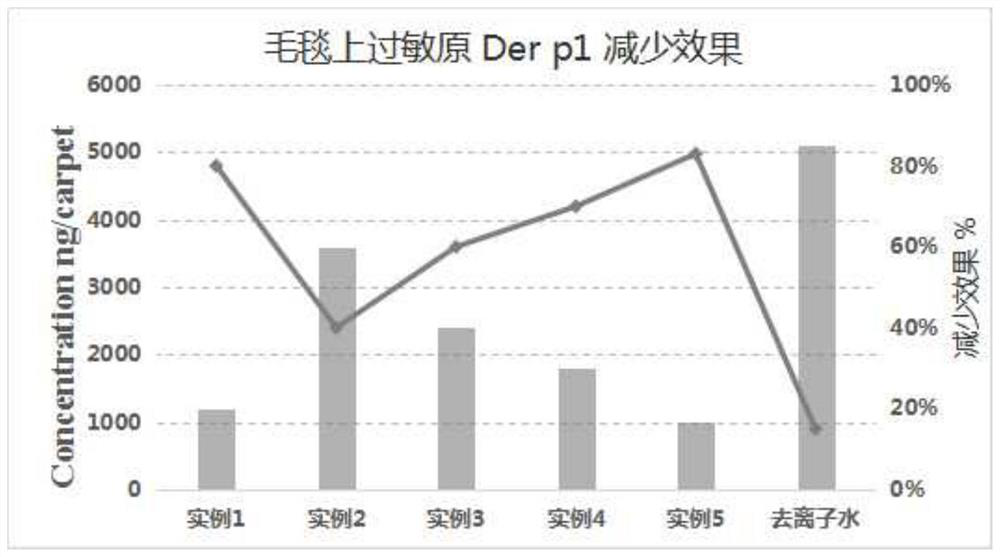

Examples

Embodiment 1

[0038]Bamboo sticks about 6 cm in length and 2 cm in width and 10 g of camphor leaves were washed three times with deionized water, then placed in an oven at 120 ° C for 5 hours, dried, and the above materials were pulverized into powders with a pulverizer for subsequent use. The above-mentioned bamboo chip powder is put into NaOH cooking liquid and boiled, wherein, the NaOH concentration is 5g / L, and the cooking aid is 3g / L NaOH 2 SiO 3 , the bath ratio is 1:25, the reaction temperature is 100°C, and the reaction time is 110 minutes. After the alkali boiling is completed, the bamboo fiber extract is obtained by filtration and separation, which is set aside. Weigh 6g of crushed camphor leaves, put them into a three-necked flask, select anhydrous ethanol as an organic solvent, control the ratio of solid to liquid at 10:1, extract at a temperature of 50°C, and take a reaction time of 75min, select the organic reagent petroleum ether to distillate Extract 3 times to obtain camph...

Embodiment 2

[0041] Bamboo sticks about 6 cm in length and 2 cm in width and 10 g of camphor leaves were washed three times with deionized water, then placed in an oven at 120 ° C for 5 hours, dried, and the above materials were pulverized into powders with a pulverizer for subsequent use. The above-mentioned bamboo chip powder is put into NaOH cooking liquid and boiled, wherein, the NaOH concentration is 5g / L, and the cooking aid is 3g / L NaOH 2 SiO 3 , the bath ratio is 1:25, the reaction temperature is 100°C, and the reaction time is 110 minutes. After the alkali boiling is completed, the bamboo fiber extract is obtained by filtration and separation, which is set aside. Weigh 6g of crushed camphor leaves, put them into a three-necked flask, select anhydrous ethanol as an organic solvent, control the ratio of solid to liquid at 10:1, extract at a temperature of 50°C, and take a reaction time of 75min, select the organic reagent petroleum ether to distillate Extract 3 times to obtain camp...

Embodiment 3

[0044] Bamboo sticks about 6 cm in length and 2 cm in width and 10 g of camphor leaves were washed three times with deionized water, then placed in an oven at 120 ° C for 5 hours, dried, and the above materials were pulverized into powders with a pulverizer for subsequent use. The above-mentioned bamboo chip powder is put into NaOH cooking liquid and boiled, wherein, the NaOH concentration is 5g / L, and the cooking aid is 3g / L NaOH 2 SiO 3 , the bath ratio is 1:25, the reaction temperature is 100°C, and the reaction time is 110 minutes. After the alkali boiling is completed, the bamboo fiber extract is obtained by filtration and separation, which is set aside. Weigh 6g of crushed camphor leaves, put them into a three-necked flask, select anhydrous ethanol as an organic solvent, control the ratio of solid to liquid at 10:1, extract at a temperature of 50°C, and take a reaction time of 75min, select the organic reagent petroleum ether to distillate Extract 3 times to obtain camp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com