Manganous-manganic oxide-graphene sheet nano-compound, as well as preparation method and application thereof

A nano-composite, manganese tetroxide technology, applied in the directions of carbon compounds, chemical instruments and methods, manganese oxide/manganese hydroxide, etc., can solve the problem of complex modification methods and preparation methods, time-consuming and energy-consuming, cycle Poor stability and other problems, to achieve the effect of accelerating reaction kinetics, small size, and strong structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

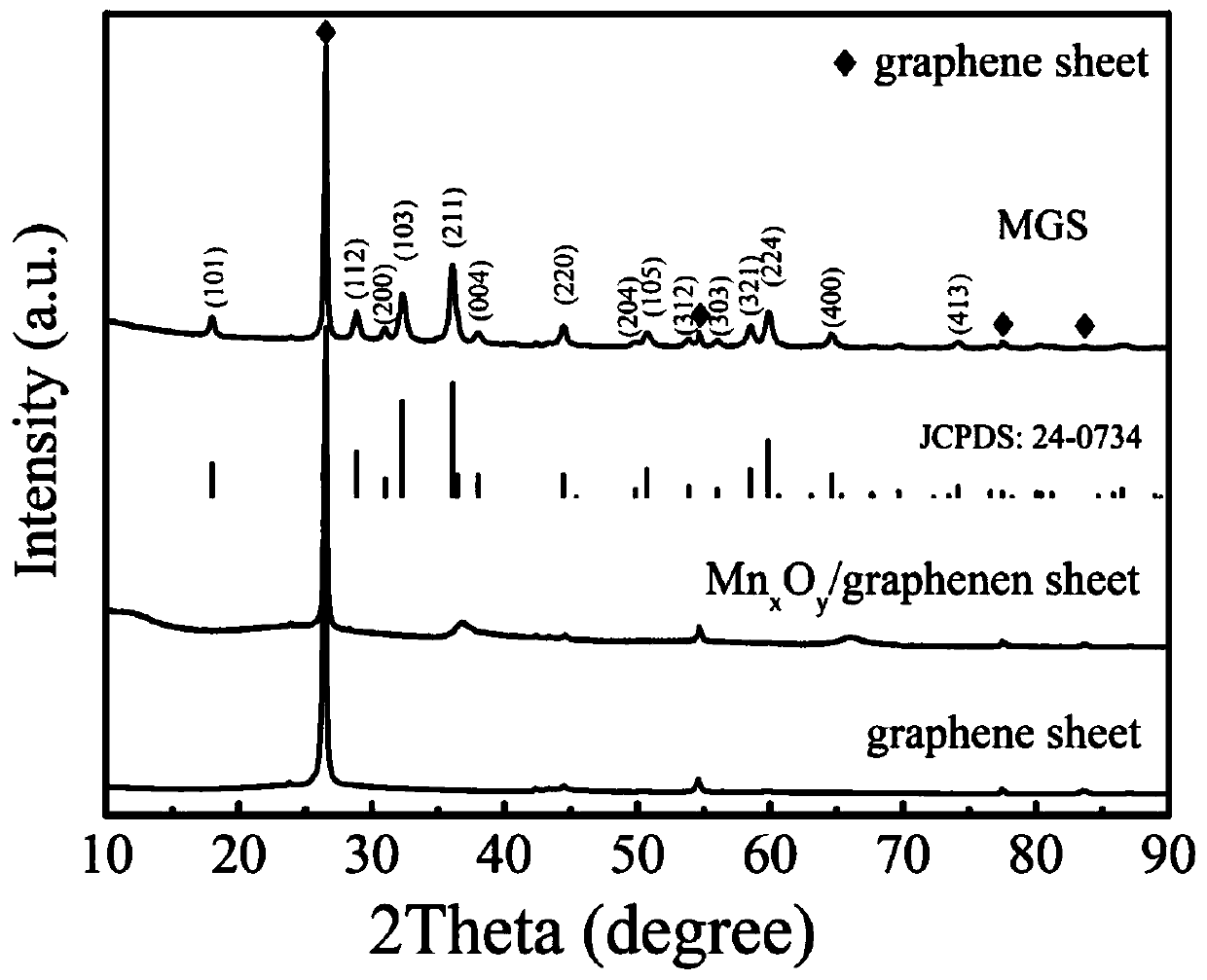

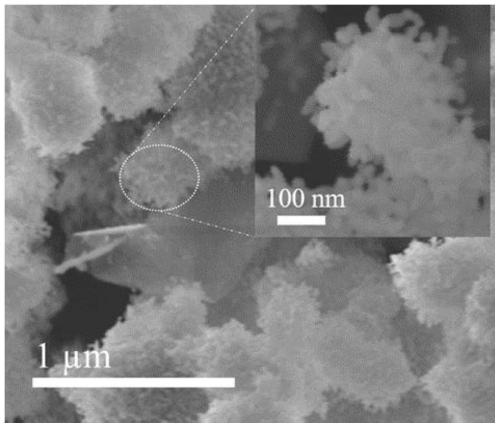

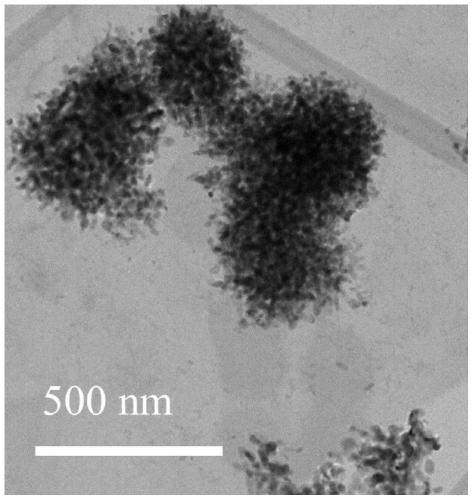

[0041] The preparation method of trimanganese tetraoxide-graphene sheet nanocomposite described in the present embodiment is specifically as follows:

[0042] (1) Put 0.2 g of graphene sheets in a 100 mL beaker, add 50 mL of deionized water, and ultrasonically dissolve to obtain a graphene sheet solution.

[0043] (2) Add 0.2 g of manganese chloride tetrahydrate into the graphene sheet solution, ultrasonically dissolve, and stir at room temperature for 30 minutes to obtain a manganese salt graphene sheet reaction solution.

[0044] (3) 0.2 g of potassium permanganate was dissolved in 10 ml of deionized water, and ultrasonically dissolved to obtain a potassium permanganate solution.

[0045] (4) Mix the products of step (2) and step (3), stir and react at 60° C. for 0.5 hour, precipitate, wash, and dry to obtain a manganese oxide-graphene sheet composite.

[0046] (5) heat-treating the manganese oxide-graphene sheet composite obtained in step (4) at 250° C. for 4 h in a nitrog...

Embodiment 2

[0051] The preparation method of trimanganese tetraoxide-graphene sheet nanocomposite described in the present embodiment is specifically as follows:

[0052] (1) Put 0.1 g of graphene sheets in a 100 mL beaker, add 50 mL of ethanol, and ultrasonically dissolve to obtain a graphene sheet solution.

[0053] (2) Add 0.2 g of manganese chloride tetrahydrate into the graphene sheet solution, ultrasonically dissolve, and stir at room temperature for 30 minutes to obtain a manganese salt graphene sheet reaction solution.

[0054] (3) Dissolve 0.3 g of potassium permanganate in 10 ml of ethanol, and ultrasonically dissolve to obtain potassium permanganate solution.

[0055] (4) Mix the products of step (2) and step (3), stir and react at 60° C. for 0.5 hour, precipitate, wash, and dry to obtain a manganese oxide / graphene sheet composite.

[0056] (5) heat-treating the manganese oxide / graphene sheet composite obtained in step (4) at 250° C. for 4 h in a nitrogen atmosphere to obtain ...

Embodiment 3

[0060] The preparation method of trimanganese tetraoxide-graphene sheet nanocomposite described in the present embodiment is specifically as follows:

[0061] (1) Put 0.5 g of graphene sheets in a 100 mL beaker, add 50 mL of isopropanol, and ultrasonically dissolve to obtain a graphene sheet solution.

[0062] (2) 0.1 g of manganese sulfate was added to the graphene sheet solution, ultrasonically dissolved, and stirred at room temperature for 30 minutes to obtain a manganese salt graphene sheet reaction solution.

[0063] (3) Dissolve 0.2 g of potassium permanganate in 10 ml of isopropanol, and ultrasonically dissolve to obtain a potassium permanganate solution.

[0064] (4) Mix the products of step (2) and step (3), stir and react at 60° C. for 0.5 hour, precipitate, wash, and dry to obtain a manganese oxide / graphene sheet composite.

[0065] (5) heat-treating the manganese oxide / graphene sheet composite obtained in step (4) at 250° C. for 4 h in a nitrogen atmosphere to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com