Building material prepared from ferro-nickel slag

A technology for building materials and nickel-iron slag, applied in the field of building materials, can solve the problems of high process cost, excessive addition, poor economy, etc., and achieve the effects of reducing accumulated pores, reducing production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

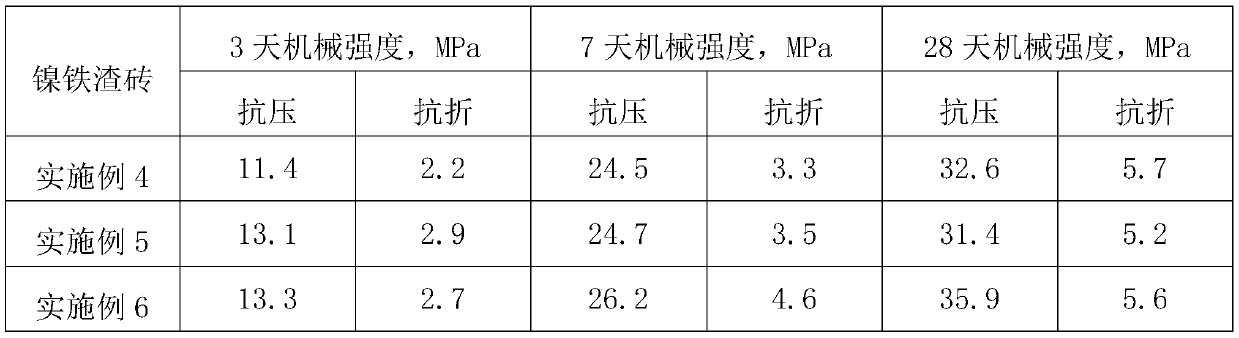

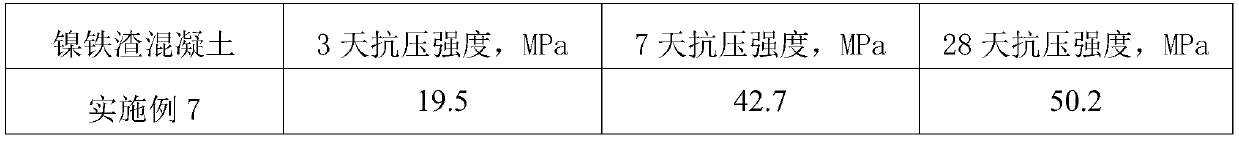

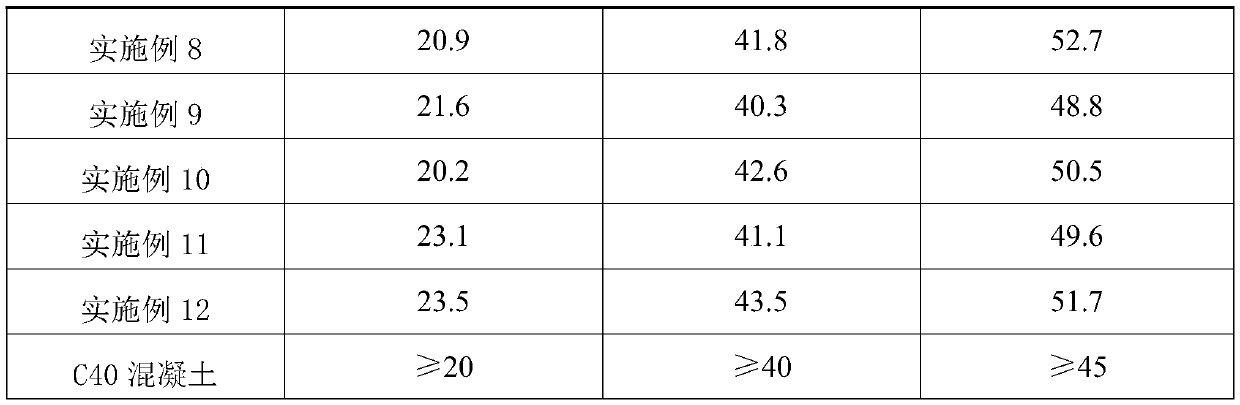

Examples

Embodiment 1

[0036] Nickel-iron slag ceramsite, nickel-iron slag concrete, nickel-iron slag brick

[0037] A ferronickel slag ceramsite prepared from ferronickel slag, comprising the following raw materials in parts by mass: 70 parts of ferronickel slag, 10 parts of slag, 10 parts of fly ash, 5 parts of gypsum, 5 parts of steel slag, sodium lignosulfonate 0.25 parts of water agent, 0.25 parts of polycarboxylate superplasticizer, 0.5 parts of defoamer, and 14 parts of water.

[0038] The preparation method of ferronickel slag ceramsite comprises the following steps:

[0039] (1) Add ferronickel slag to the ball mill, add appropriate amount of water for wet milling, collect ferronickel slag with particle size less than 100 mesh and dry for later use;

[0040] (2) Take by weighing each solid raw material according to the proportioning requirements, mix in a ball mill until evenly used;

[0041] (3) The mixture obtained is added to the granulator, and the corresponding moisture is weighed ac...

Embodiment 2

[0044] A ferronickel slag ceramsite prepared from ferronickel slag, comprising the following raw materials in parts by mass: 50 parts of ferronickel slag, 10 parts of slag, 15 parts of fly ash, 10 parts of gypsum, 5 parts of steel slag, sodium lignosulfonate 0.25 parts of water agent, 0.25 parts of polycarboxylate superplasticizer, 0.7 parts of defoamer, and 19 parts of water.

[0045] The preparation method of ferronickel slag ceramsite comprises the following steps:

[0046] (1) Add ferronickel slag to the ball mill, add appropriate amount of water for wet milling, collect ferronickel slag with particle size less than 100 mesh and dry for later use;

[0047] (2) Take by weighing each solid raw material according to the proportioning requirements, mix in a ball mill until evenly used;

[0048] (3) The mixture obtained is added to the granulator, and the corresponding moisture is weighed according to the proportioning requirements and poured into the granulator, and granulate...

Embodiment 3

[0051] A ferronickel slag ceramsite prepared from ferronickel slag, comprising the following raw materials in parts by mass: 55 parts of ferronickel slag, 20 parts of slag, 12 parts of fly ash, 5 parts of gypsum, 8 parts of steel slag, sodium lignosulfonate 0.25 parts of water agent, 0.25 parts of polycarboxylate superplasticizer, 1 part of defoamer, and 12 parts of water.

[0052] The preparation method of ferronickel slag ceramsite comprises the following steps:

[0053] (1) Add ferronickel slag to the ball mill, add appropriate amount of water for wet milling, collect ferronickel slag with particle size less than 100 mesh and dry for later use;

[0054] (2) Take by weighing each solid raw material according to the proportioning requirements, mix in a ball mill until evenly used;

[0055] (3) The mixture obtained is added to the granulator, and the corresponding moisture is weighed according to the proportioning requirements and poured into the granulator, and granulated at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com