A kind of preparation method of plant molluscicide luocarb

The technology of molluscicide and molluscicide, which is applied in the field of synthesis of known compounds, can solve problems such as not going deep into the process, and achieve the effects of process operation, low energy consumption and reduction of separation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

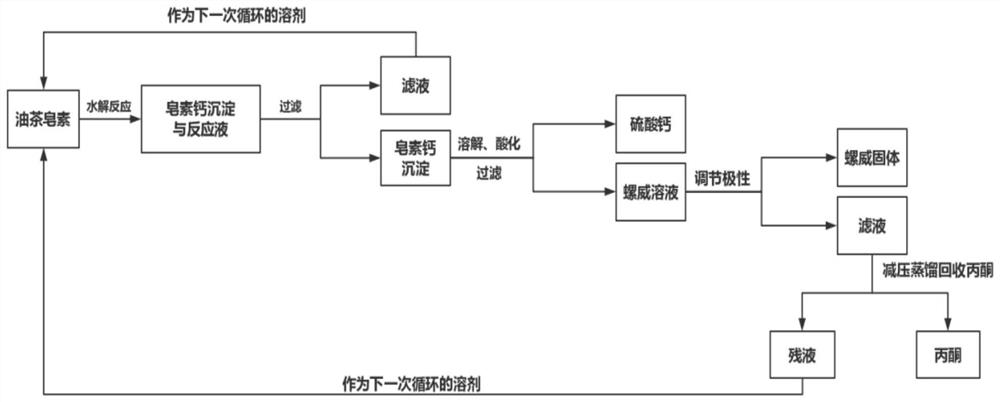

Method used

Image

Examples

Embodiment 1

[0054] 1, hydrolysis, calcification of oil saponin

[0055] 1.1 g of calcium hydroxide in three flasks, add 75 mL of deion, mix well, and weigh 8.3 g of oil tea saponin (mass fraction of 60%, oil-containing tea sapin 5g), stir mix and mix, It is heated to 40 ° C, stirring using a stirrer, stably reacting 12h, obtaining soil saponin calcium, wash 1 to 2 times with a small amount of deionized water. After filtration with vacuum pump, the saponin is placed in a vacuum drying tank for 12 h drying for 12 h, i.e., 6.4 g of dry saponin calcium, yield of 77.1%.

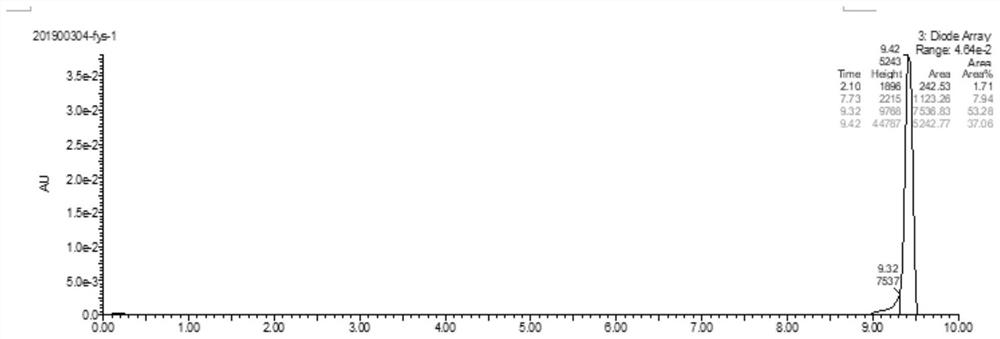

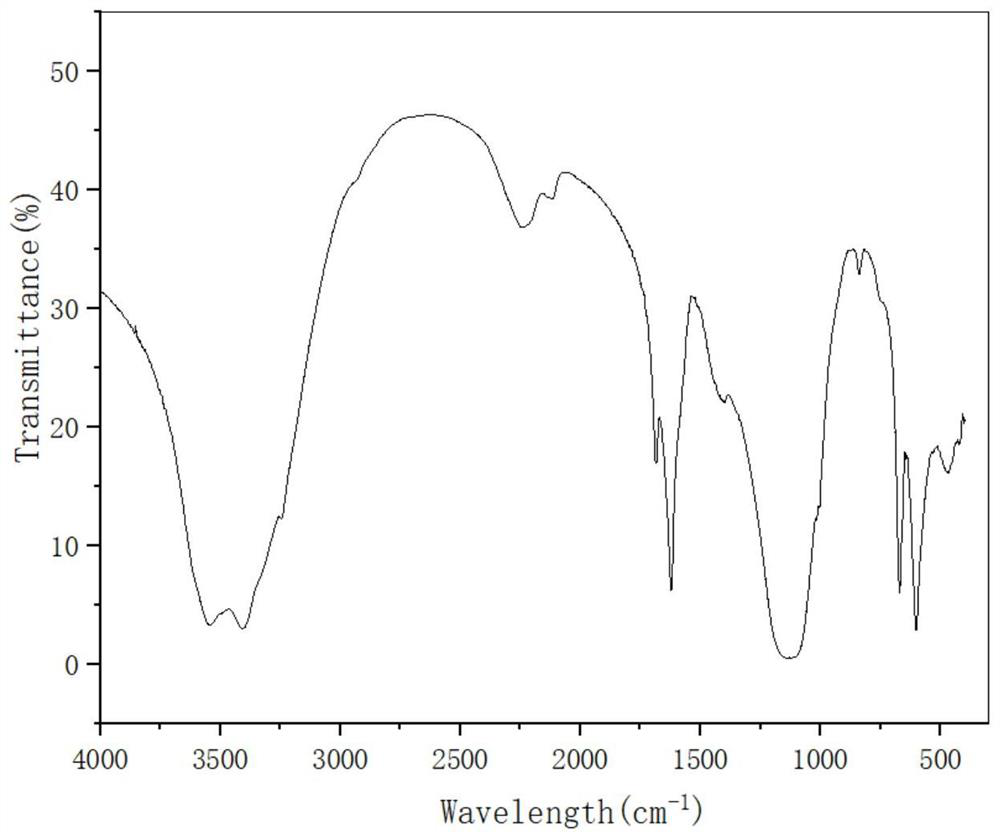

[0056] 2, saponin calcium acidification macrower

[0057] The saponin solid obtained by the previous step was dispersed with 100 ml of deionized water, and stirring was carried out with a magnetic stirring child, and the mass fraction was dripped at room temperature, and the soil-yellow solid was gradually dissolved, and the bottom of the solution was White calcium sulfate precipitate. When the pH is stabilized between 4 to 5, th...

Embodiment 2

[0061] 1, hydrolysis, calcification of oil saponin

[0062] Weigh 1.1 g of calcium hydroxide in three flasks, add 75 ml of deion, mix well, and weigh 8.3 g of oil tea saponin (mass fraction of 60%, oil-containing tea 5G) mixed, heating it To 50 ° C, the reaction was stably reacted for 12 h, and the soil-yellow saponin calcium was obtained, 1 to 2 times with a small amount of deionized water. After filtration with vacuum pump, the saponin was placed in a vacuum drying tank 50-75 ° C for 12 h, ie 7.1 g of dry saponin calcium, yield was 85.5%.

[0063] 2, saponin calcium acidification macrower

[0064] The saponin calcium obtained by the previous step is obtained in accordance with the operation steps in Example 1 to obtain a screw solution.

[0065] 3, snail refining

[0066] According to the operation step in Example 1, a sciile solution can be obtained from a sciile solid body 3.8 g, and the yield is 46%. The filtrate was distilled with Embodiment 1.

Embodiment 3

[0068] 1.1 g of calcium hydroxide in three flasks, add 75 mL of deion, mix well, and weigh 8.3 g of oil tea saponin (mass fraction of 60%, oil-containing tea sapin 5g), stir mix and mix, It is heated to 90 ° C. The stirrer was stirred, and the reaction was stirred at 12h, the saponin calcium precipitate was not obtained, and the reaction liquid became black and accompanied by a malodant, and the reaction solution was carried with the reaction solution. The lower reaction 12h can cause oil tea saponin deterioration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com