Waterborne antirust paint with rust and preparation method of paint

A technology of anti-rust and coating with rust, applied in the field of coatings, can solve the problems of limited rust transfer ability, insufficient adhesion, environmental pollution, etc., and achieve the effect of stable chemical properties and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

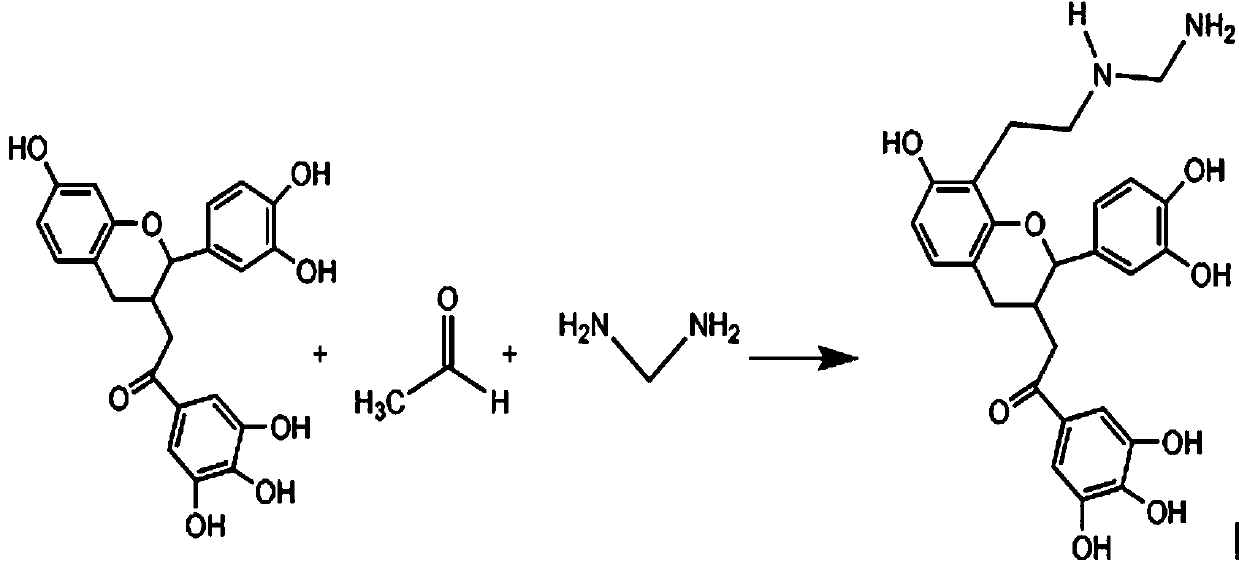

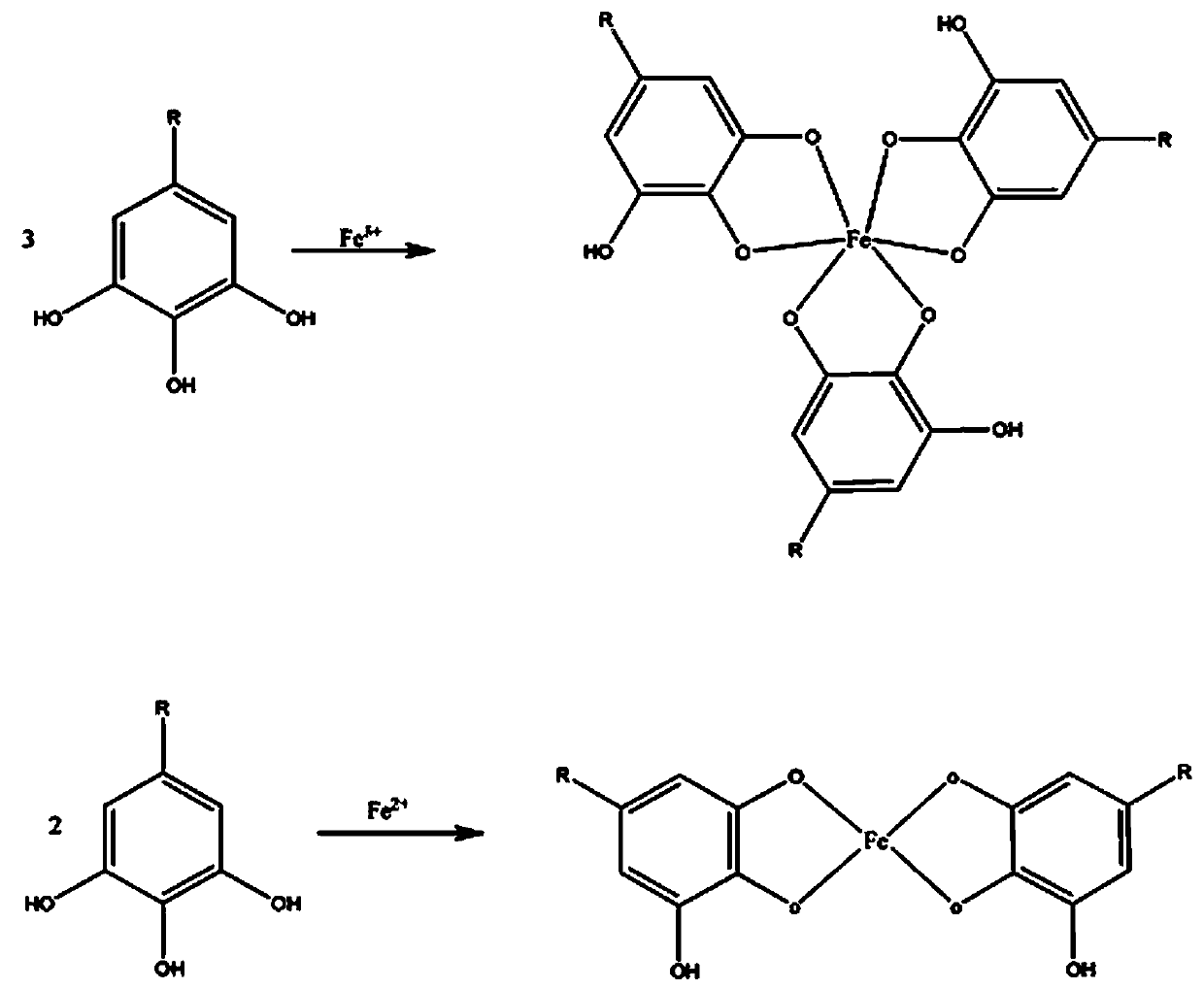

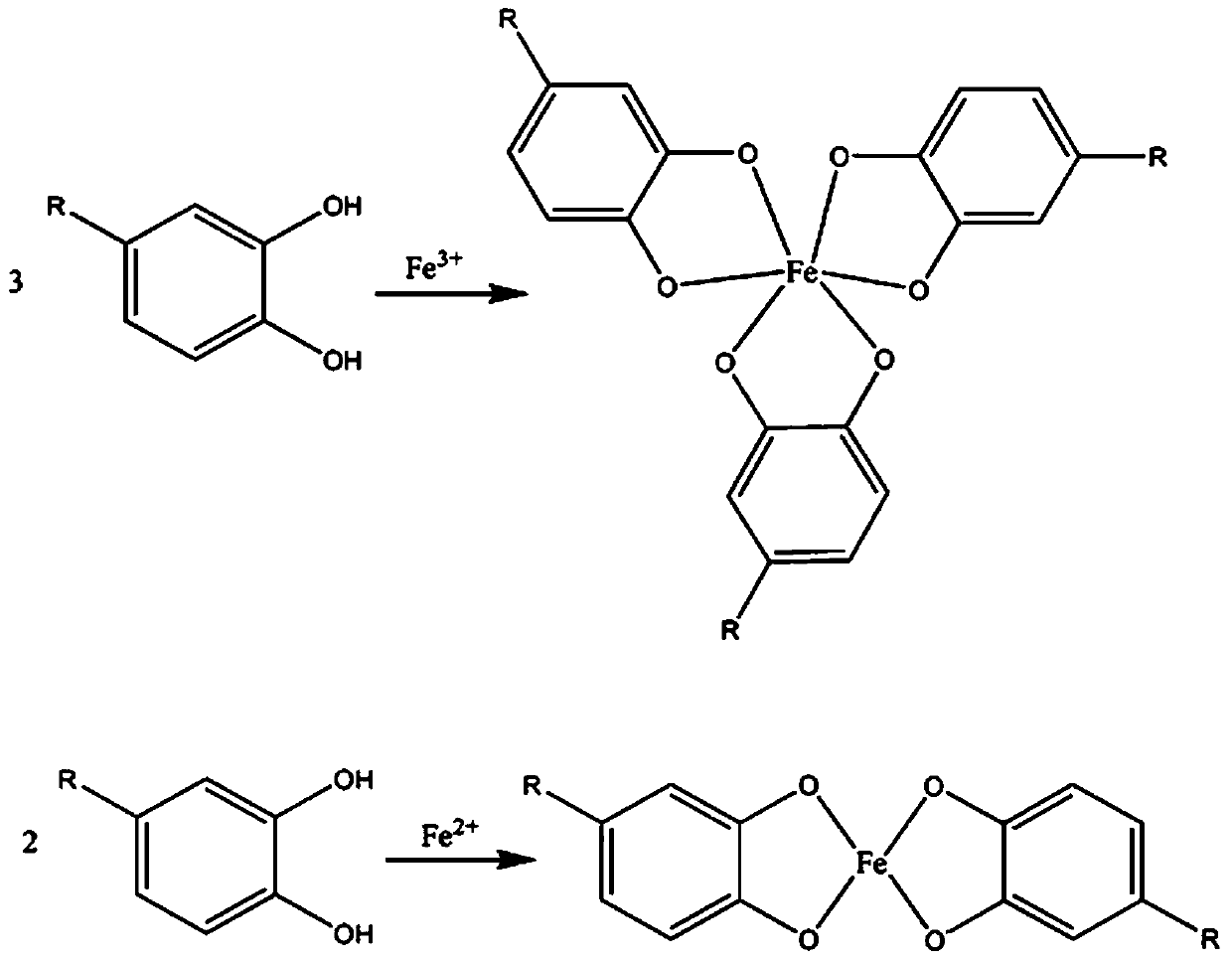

Method used

Image

Examples

Embodiment

[0038] (1) Preparation of component A.

[0039] ①Modified aluminum tripolyphosphate 13%, gallic acid 6%, thickener TCP-936 0.6%, dispersant LX-5040 0.6%, wetting agent ND-4070 0.6%, defoamer RT- 10 Add 0.4% and 21% deionized water into the mixing sand mill dispersing multi-purpose machine, stir it at high speed for 30min, and control the speed at 1800r / min.

[0040] ②Continue grinding for 1h until the fineness reaches 40μm.

[0041] ③Stir at a low speed again, and the speed is controlled at 500r / min. During the stirring process, add 55% of water-based epoxy resin, 2% of curing accelerator K-54, 0.5% of leveling agent ND-517, and 0.1% of defoamer according to weight percentage. %, thickener 0.2%, after adding all the ingredients, stir for 30 minutes.

[0042] ④ After the stirring is completed, the A component of the water-based anti-rust paint with rust is obtained.

[0043] (3) Preparation of component B.

[0044] 1. The present invention adopts the mass percent of raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com