A kind of three-layer nanoporous film and its preparation method and application

A nanoporous film and nanofilm technology, applied in the field of biochemical detection materials, can solve the problems of inaccurate detection results and low spatial resolution of DNA sequencing of three-layer nanoporous film, and achieve good adhesion, stable thin layer quality, Uniform and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

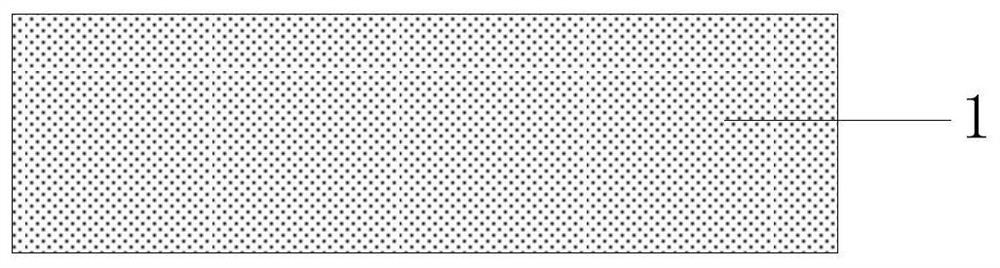

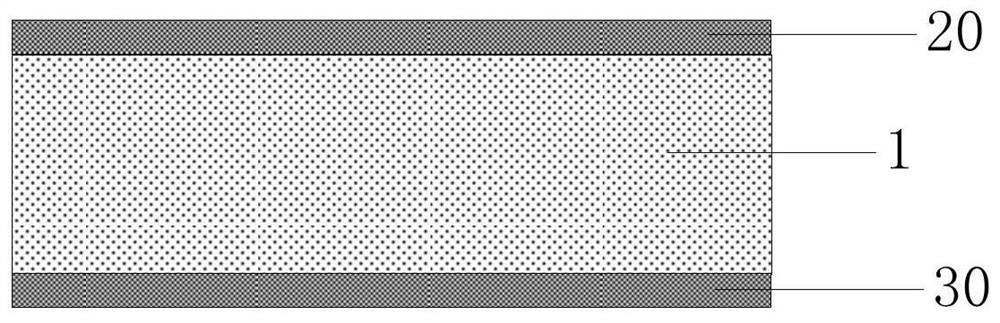

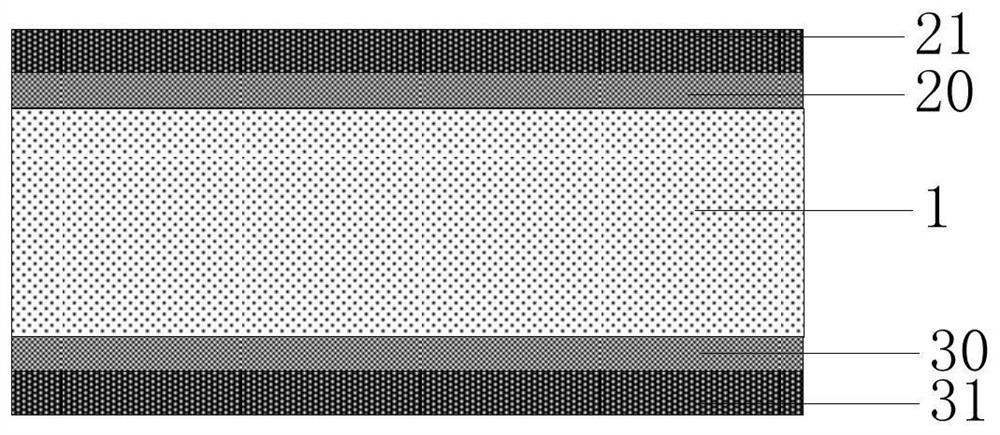

[0046] A preparation method of a three-layer nanoporous film, such as Figure 1~4 , shown in 6-8, 10, including the following steps:

[0047] S1. On the surface of both sides of the doped single crystal silicon substrate 1, adopt low-pressure chemical vapor deposition (LP-CVD) to deposit Si 3 N 4 layers (20 and 30), in Si 3 N 4 Layer surface continues to SiO 2 layers (21 and 31), forming Si 3 N 4 / SiO 2 double-layer nanostructure, where Si 3 N 4 layer thickness of 30nm, SiO 2 The thickness of the layer is 40 nm;

[0048] S2. Using atomic layer deposition of Si on one side of the substrate 3 N 4 / SiO 2 Deposition of Si on bilayer nanofilms 3 N 4 Layer 22, Si 3 N 4 layer thickness 5nm, forming Si 3 N 4 / SiO 2 / Si 3 N 4 Three-layer nanostructure;

[0049] S3. Si on the above substrate 3 N 4 / SiO 2 One side of the bilayer nanostructure etches Si by reactive ion etching 3 N 4 / SiO 2 The layer forms the matrix release window 4, and the size range of the ...

Embodiment 2

[0054] A preparation method of a three-layer nanoporous film, comprising the steps of:

[0055] S1. Deposit Si on both sides of the doped polysilicon substrate by low-pressure chemical vapor deposition (LP-CVD) 3 N 4 layer, in Si 3 N 4 Layer surface continues to SiO 2 layer, forming Si 3 N 4 / SiO 2 double-layer nanostructure, where Si 3 N 4 layer thickness of 100nm, SiO 2 The thickness of the layer is 100nm;

[0056] S2. Using atomic layer deposition of Si on one side of the substrate 3 N 4 / SiO 2 Deposition of Si on bilayer nanofilms 3 N 4 layer, Si 3 N 4 layer thickness 5nm, forming Si 3 N 4 / SiO 2 / Si 3 N 4 Three-layer nanostructure;

[0057] S3. Si on the above substrate 3 N 4 / SiO 2 One side of the bilayer nanostructure etches Si by reactive ion etching 3 N 4 / SiO 2 The layer forms a matrix release window with a size range of 800 μm × 800 μm;

[0058] S4. Use an alkaline solution to etch the substrate from the substrate release window to obtai...

Embodiment 3

[0062] A preparation method of a three-layer nanoporous film, comprising the steps of:

[0063] S1. adopt low-pressure chemical vapor deposition (LP-CVD) to deposit Si on the surface of both sides of the germanium substrate 1 after doping 3 N 4 layer, in Si 3 N 4 Layer surface continues to SiO 2 layer, forming Si 3 N 4 / SiO 2 double-layer nanostructure, where Si 3 N 4 layer thickness of 200nm, SiO 2 The thickness of the layer is 200nm;

[0064] S2. Using atomic layer deposition of Si on one side of the substrate 3 N 4 / SiO 2 Deposition of Si on bilayer nanofilms 3 N 4 layer, Si 3 N 4 layer thickness 5nm, forming Si 3 N 4 / SiO 2 / Si 3 N 4 Three-layer nanostructure;

[0065] S3. Si on the above substrate 3 N 4 / SiO 2 One side of the bilayer nanostructure etches Si by reactive ion etching 3 N 4 / SiO 2 The layer forms a matrix release window with a size range of 800 μm × 800 μm;

[0066] S4. Use an alkaline solution to etch the substrate from the substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com