Preparation method of magnetic polyurethane elastic fiber

A technology of polyurethane elasticity and polyurethane, which is applied in the field of preparation of magnetic polyurethane elastic fibers, can solve problems such as scarcity, and achieve the effects of preventing magnetic powder agglomeration, good fiber safety and environmental protection, and excellent magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

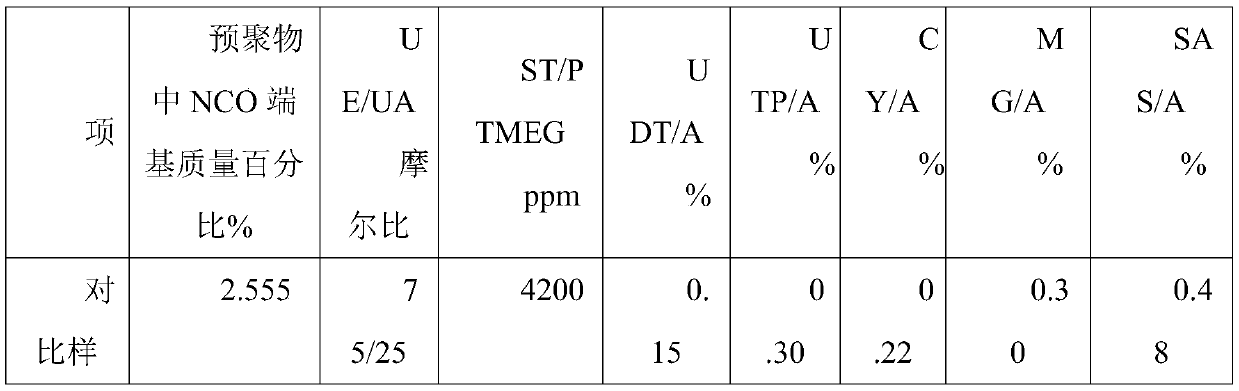

[0019] A kind of preparation method of magnetic polyurethane elastic fiber of the present invention obtains slurry solution (auxiliary material solution) that magnetic powder is uniformly dispersed through grinding and emulsifying, and slurry solution is prepared by adding polyurethane polymer into magnetic polyurethane spinning stock solution and stock solution dry spinning Silk is made through three main processes, and its features include:

[0020] 1. The magnetic powder is iron oxide magnetic powder (γ-Fe2O3), iron oxide magnetic powder modified by methods such as doping, adsorption, infiltration, and coating of certain elements, chromium dioxide magnetic powder (CrO2), metal magnetic powder and barium iron Oxygen and other magnetic powder, iron oxide magnetic powder is preferred, and the particle size of the magnetic powder is controlled at <1um.

[0021] 2. The solvent is N,N-dimethylformamide DMF, N,N-dimethylacetamide DMAC, N,N-diethylformamide DEF and other amide homo...

Embodiment 1-3

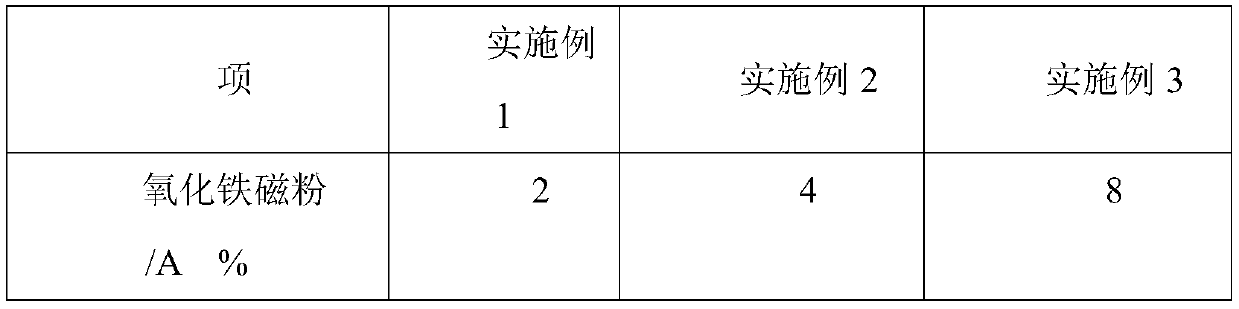

[0042] The preparation of embodiment 1-3 experimental sample

[0043] When preparing the samples of Examples 1-3, the experimental operation method was the same as that of the comparative sample, except that a certain amount of iron oxide magnetic powder (γ-Fe2O3) was added when the emulsified slurry solution was prepared, and the addition ratio of the magnetic powder As shown in the table below:

[0044] Table 2 Experimental sample 1-3 Magnetic agent addition data table

[0045]

[0046] Wherein: A is the solid content of the polymer polymerized by RA2, that is, A is the mass sum of the following substances:

[0047] A=m PTMEG +m MDI +m UE +m UA +m CEPPA +m ST +m SPA

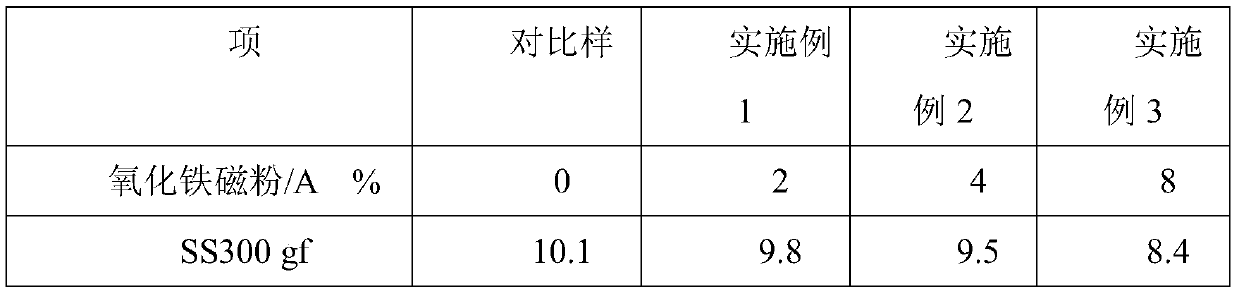

[0048] Each embodiment polyurethane elastic fiber physical index is listed in table 4:

[0049] Table 3 each embodiment polyurethane elastic fiber physical property index

[0050]

[0051]

[0052] As can be seen from the physical properties in Table 3, the formula of Example 2 is selected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com