Supercritical carbon dioxide circulation flue gas waste heat recovery coal-fired power generation system and operation method

A technology of carbon dioxide and circulating flue gas, which is applied in preheating, steam superheating, steam generation, etc., can solve the problems of high boiler exhaust gas temperature, reduced boiler efficiency, and low heat absorption load, so as to reduce exhaust gas temperature and improve boiler efficiency. The effect of high efficiency and cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

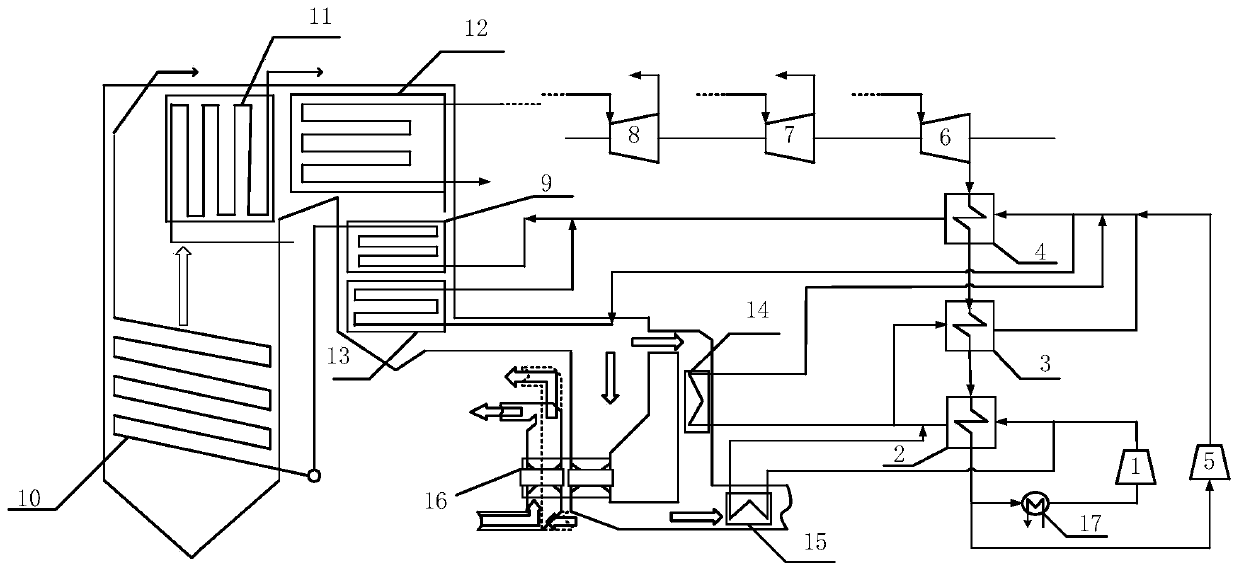

[0023] Such as figure 1 As shown, a supercritical carbon dioxide circulation flue gas waste heat recovery coal-fired power generation system includes a precooler 17, a main compressor 1, a low-temperature regenerator 2, a medium-temperature regenerator 3, and a high-temperature regenerator 4 connected in sequence. , economizer 9, superheated gas wall 10, high pressure turbine 8, medium pressure reheater 11, medium pressure turbine 7, low pressure reheater 12 and low pressure turbine 6; also includes recompressor 5, rotary Air preheater 16, high-temperature flue gas heat exchanger 13, medium-temperature flue gas heat exchanger 14, and low-temperature flue gas heat exchanger 15; low-pressure turbine 6 exhausts in the high-temperature regenerator 4, medium-temperature regenerator 3 and The heat is released in the low-temperature regener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com