Nitrogen-containing graphene coated biomass carbon negative material and preparation method thereof

A graphene-coated, biomass carbon technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of difficult processing, low cycle stability, unstable structure, etc., and achieve low cost and excellent cycle stability. , the effect of the best high current charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

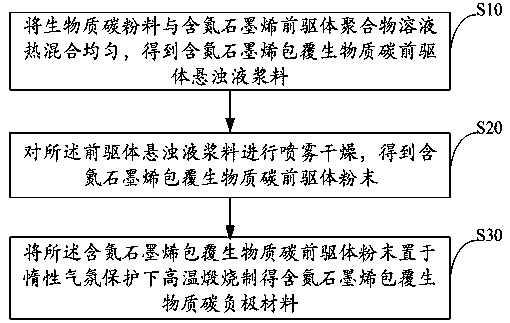

[0035] See figure 1 A method for preparing a nitrogen-containing graphene-coated biomass carbon negative electrode material provided by the invention comprises the steps of:

[0036] S10. Thermally mixing the biomass carbon powder with the nitrogen-containing graphene precursor polymer solution to obtain a nitrogen-containing graphene-coated biomass carbon precursor suspension slurry (micro-cured and cross-linked state);

[0037] S20. Spray drying the precursor suspension slurry to obtain nitrogen-containing graphene-coated biomass carbon precursor powder;

[0038] S30. Calcining the nitrogen-containing graphene-coated biomass carbon precursor powder at a high temperature under the protection of an inert atmosphere to obtain a nitrogen-containing graphene-coated biomass carbon negative electrode material.

[0039] In a preferred embodiment, the biomass carbon powder is prepared by the following method:

[0040] S01. Take a certain amount of plant raw material, dehydrate it, ...

Embodiment 1

[0070] Take 100 g of corn stalks and place them in a blast oven for dehydration at 120°C for 24 hours. Place the dehydrated plant material in an inert atmosphere at a heating rate of 10°C / min to 900°C, carbonize for 6 hours, and then use a traditional Chinese medicine pulverizer to Crushing treatment is carried out to obtain primary biomass carbon powder with a particle size range of 10-18 μm. The primary crushed product was placed in a blast oven for micro-oxidation treatment at 150° C. for 24 hours to obtain a micro-oxidized intermediate biomass carbon powder. Mix the medium-grade biomass carbon powder with 0.5mol / L oxalic acid solution according to the mass ratio of 1:1, and stir for 6 hours under mechanical stirring to obtain an acidic suspension. The acidic suspension is filtered to remove the filtrate, and the obtained solid is washed with deionized water several times until the filtrate is neutral to obtain high-purity biomass carbon powder. The obtained biomass carbon...

Embodiment 2

[0072]Take 100 g of sawdust and place it in a blast oven for dehydration at 120°C for 24 hours, place the dehydrated plant material in an inert atmosphere at a rate of 10°C / min to 900°C, carbonize for 6 hours, and then use a traditional Chinese medicine pulverizer Crushed to obtain primary biomass carbon powder with a particle size range of 10-18 μm. The primary crushed product was placed in a blast oven for micro-oxidation treatment at 150° C. for 24 hours to obtain a micro-oxidized intermediate biomass carbon powder. Mix the medium-grade biomass carbon powder with 0.5mol / L oxalic acid solution according to the mass ratio of 1:1, and stir for 6 hours under mechanical stirring to obtain an acidic suspension. The acidic suspension is filtered to remove the filtrate, and the obtained solid is washed with deionized water several times until the filtrate is neutral to obtain high-purity biomass carbon powder. The obtained biomass carbon powder and the nitrogen-containing graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com