Resist substrate pretreatment composition and method for producing resist substrate

A resist and pretreatment technology, applied in the direction of detergent composition, surface active detergent composition, chemical instruments and methods, etc., can solve the problems of large wetting expansion, low viscosity, exudation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

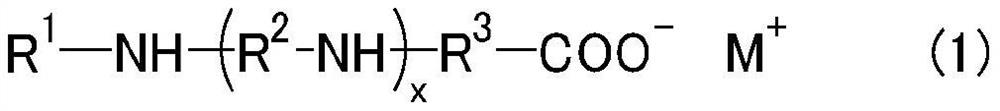

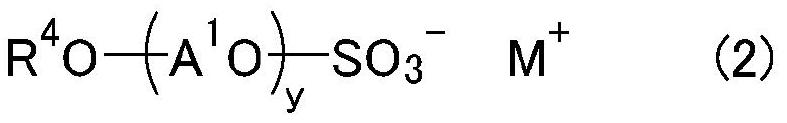

Method used

Image

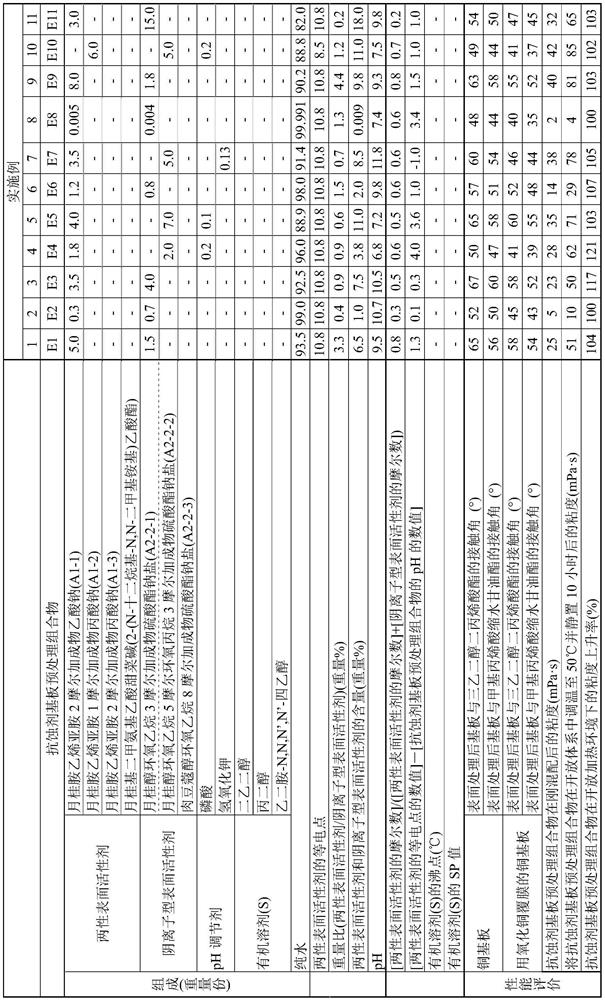

Examples

manufacture example 1

[0102] Put 205 parts of chlorododecane and 103 parts of diethylenetriamine into a stainless steel autoclave with stirring and temperature adjustment functions, replace the mixed system with nitrogen, and carry out approx. 1 hour reaction. Cool after the reaction, add aqueous sodium hydroxide solution, stir and let stand for liquid separation. After removing the lower layer (aqueous layer), the gas layer part was replaced with nitrogen, and vacuum distillation was performed (distillation conditions of the main product: 185° C. to 240° C., 5 mmHg to 20 mmHg). Put water and 271 parts of the main product into a glass reaction container, while blowing nitrogen gas into the gas layer, add an aqueous solution of monochloroacetic acid (95 parts) at 50°C to 100°C, and react at 90°C to 110°C Afterwards, the pH was adjusted with aqueous sodium hydroxide solution to obtain sodium acetate (A1-1), a 2-mol adduct of laurylamine ethyleneimine.

manufacture example 2

[0104] Put 205 parts of chlorododecane and 60 parts of ethylenediamine into a stainless steel autoclave with stirring and temperature adjustment functions, replace the inside of the mixed system with nitrogen, and then react at 80°C to 120°C for about 1 hour . Cool after the reaction, add aqueous sodium hydroxide solution, stir and let stand for liquid separation. After removing the lower layer (aqueous layer), the gas layer part was replaced with nitrogen, and vacuum distillation was performed (distillation conditions of the main product: 185° C. to 240° C., 5 to 20 mmHg). Put water and 271 parts of the main product into a glass reaction container, while blowing nitrogen gas into the gas layer, add an aqueous solution of monochloropropionic acid (109 parts) at 50 ° C to 100 ° C, and then add it at 90 ° C ~ 110 ° C After the reaction, the pH was adjusted with aqueous sodium hydroxide solution to obtain sodium propionate (A1-2), a 1 mole adduct of laurylamine ethyleneimine.

manufacture example 3

[0106] Put 205 parts of chlorododecane and 103 parts of diethylenetriamine into a stainless steel autoclave with stirring and temperature adjustment functions, replace the mixed system with nitrogen, and carry out approx. 1 hour reaction. Cool after the reaction, add aqueous sodium hydroxide solution, stir and let stand for liquid separation. After removing the lower layer (aqueous layer), the gas layer part was replaced with nitrogen, and vacuum distillation was performed (distillation conditions of the main product: 185° C. to 240° C., 5 to 20 mmHg). Put water and 271 parts of the main product into a glass reaction container, while blowing nitrogen gas into the gas layer, add an aqueous solution of monochloropropionic acid (109 parts) at 50 ° C to 100 ° C, and then add it at 90 ° C ~ 110 ° C After the reaction, the pH was adjusted with aqueous sodium hydroxide solution to obtain sodium propionate (A1-3), a 2-mol adduct of laurylamine ethyleneimine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com