Butanediol low-temperature water removal device and use method thereof

A butanediol and low-temperature technology, which is applied in the field of butanediol low-temperature water removal equipment, can solve the problems of difficult distillation control in large tanks, and achieve the goals of avoiding damage to the vacuum environment, improving sealing, and improving mixed flow efficiency and effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

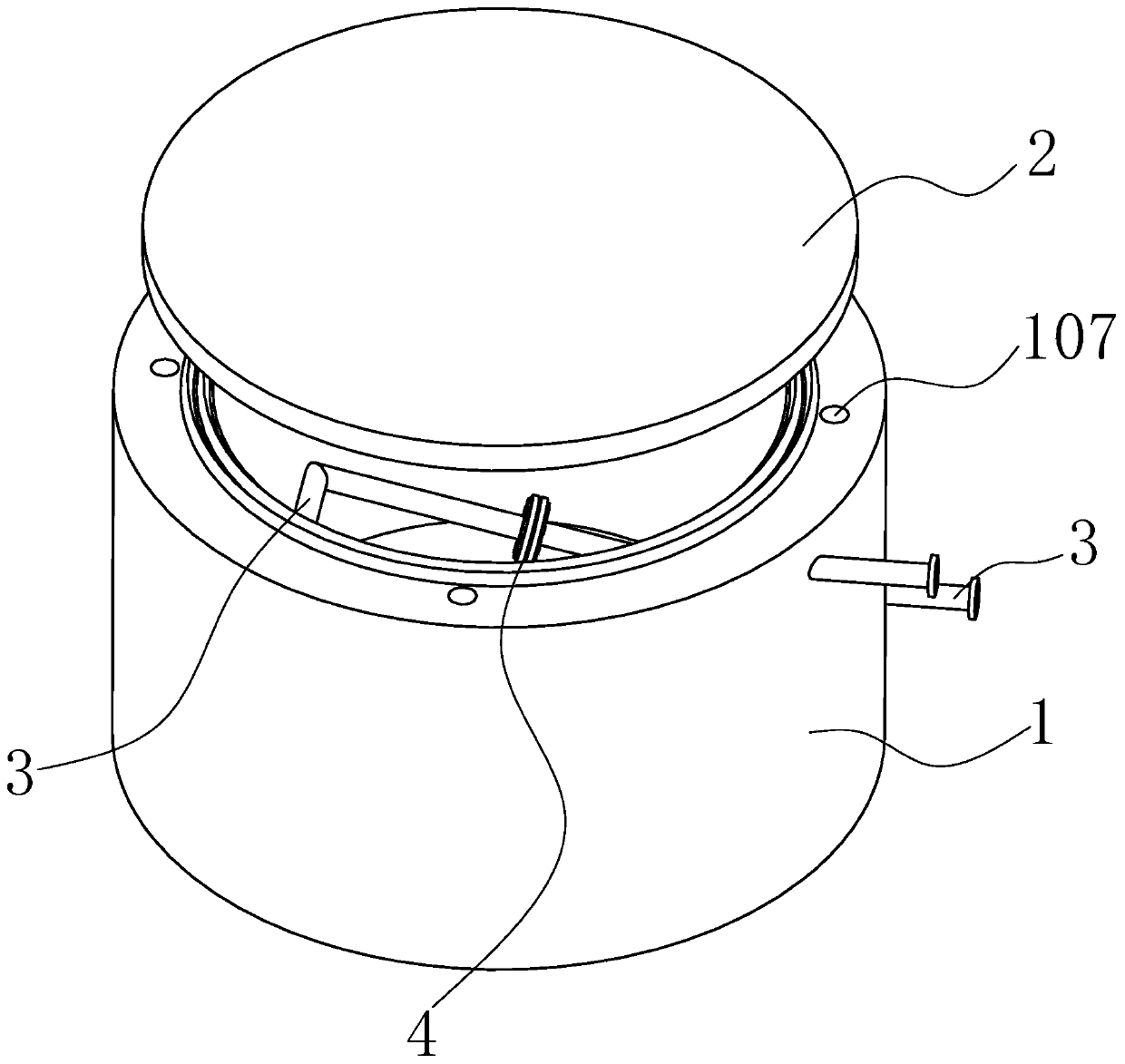

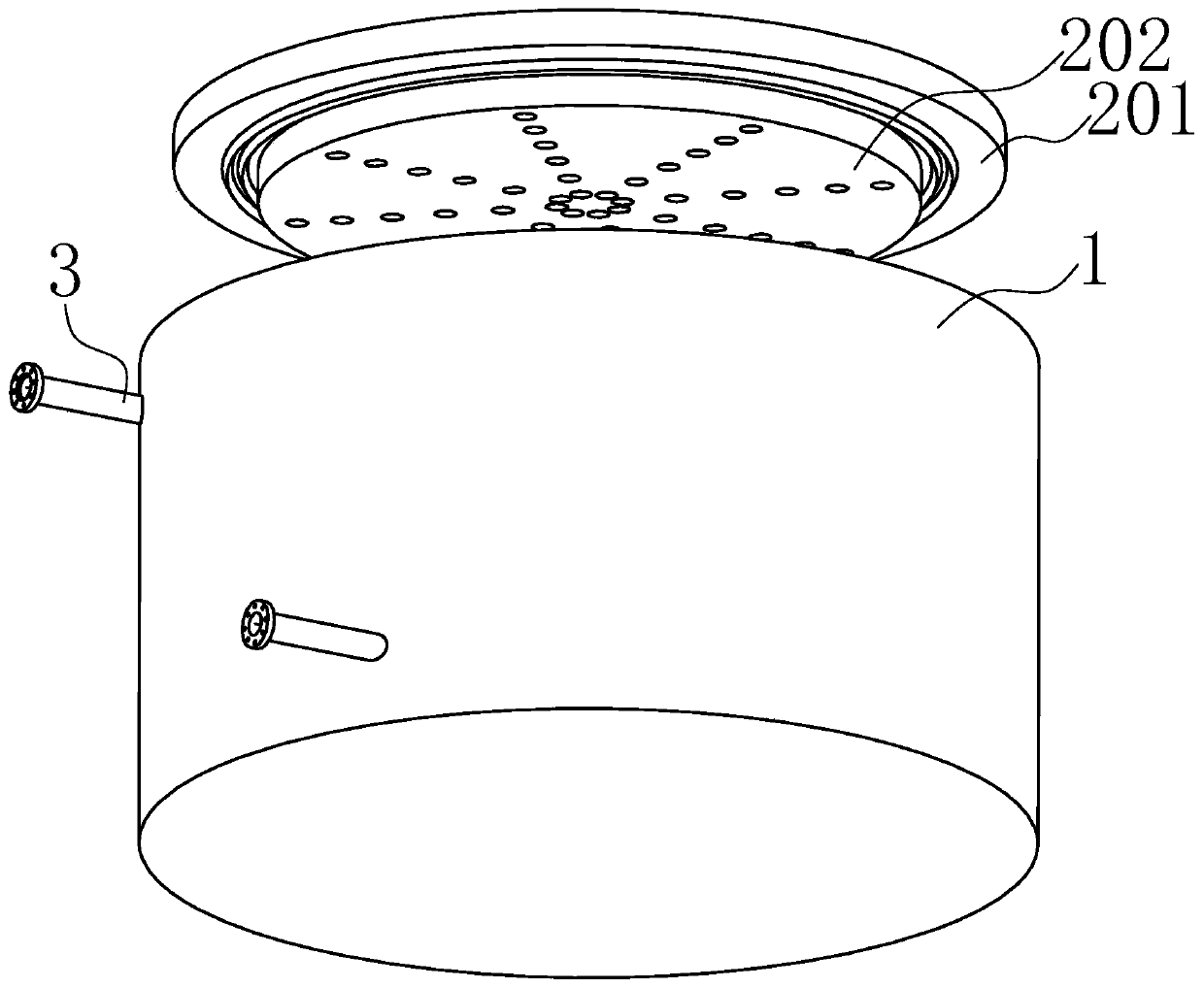

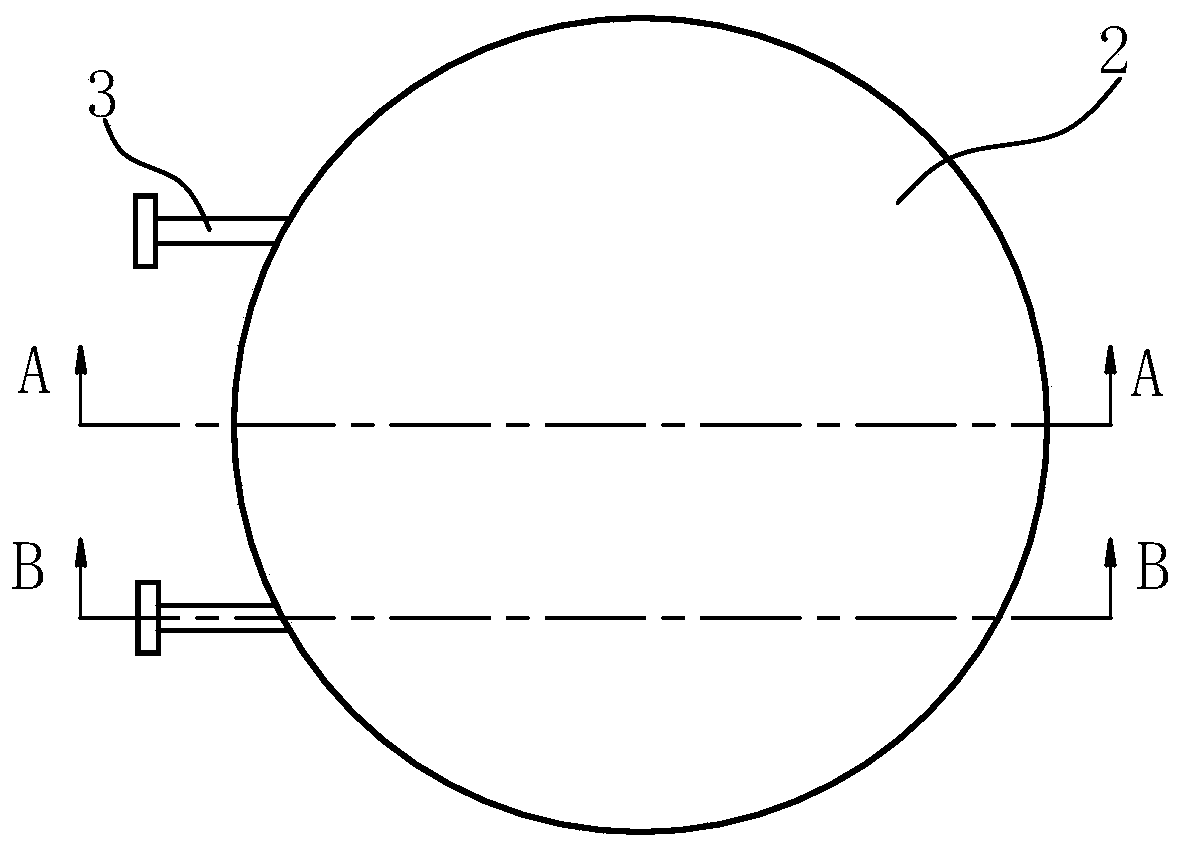

[0049] Such as Figure 1 to Figure 8 As shown, a low-temperature water removal equipment for butanediol includes a distillation kettle 1 and a cover 2 for sealing the distillation kettle 1. A heating pipe 3 for heating butanediol is passed through the distillation kettle 1. The side wall of the still 1 is a double-layer structure composed of an inner wall and an outer wall. The double-layer structure is divided into a lower space 101 and an upper space 102 that are independent of each other. The lower space 101 and the upper space 102 are both vacuumed to accommodate The purpose of heat preservation of the cavity; the outer wall of the upper space 102 is provided with a vacuum pump insertion port 103, and the inner wall of the upper space 102 is provided with a first one-way valve 104 that leads to the accommodating cavity of the distillation kettle 1, and an external vacuum pump connects the upper space The air in 102 is drawn out, and the air pressure in the accommodating cha...

Embodiment 2

[0064] On the basis that the above-mentioned other technical solutions remain unchanged, the clamping cover 301 is movably sleeved on the corresponding heating tube 3 in a threaded connection, so that the clamping cover 301 can be further adjusted.

Embodiment 3

[0066] On the basis that the above-mentioned other technical solutions remain unchanged, the deflectors 4 are used in pairs, and two oppositely arranged deflectors 4 constitute a convection device, and then the butanediol in each area is impacted and merged with each other. Flow to the surrounding area vigorously and evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com