Preparation method of platinum doped ZnO-SnO2 composite photocatalytic material

A composite photocatalysis, zno-sno2 technology, applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problem of insufficient photocatalytic degradation and photocatalytic activity. Limitation and other issues, to achieve the effect of increasing the number of active sites, good preparation effect, and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

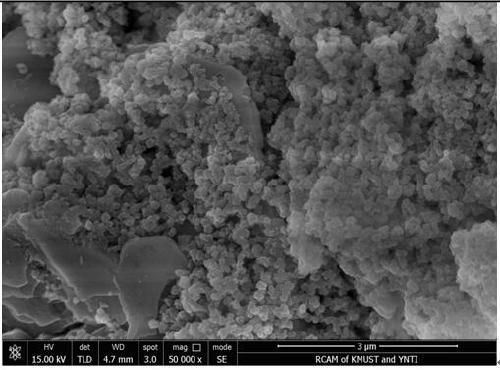

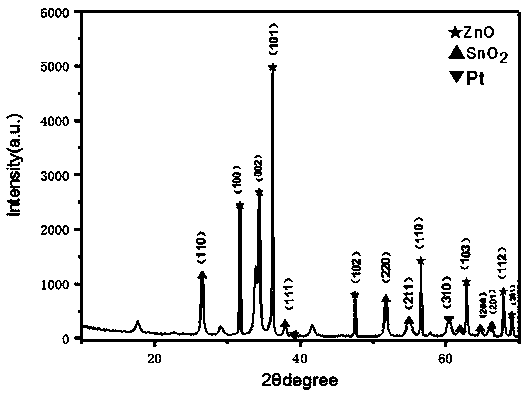

Image

Examples

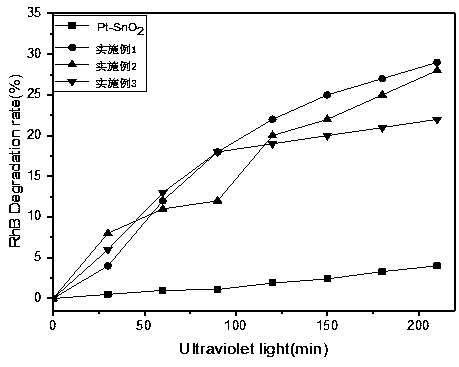

Embodiment 1

[0027] A ZnO-SnO doped with metallic platinum 2 The preparation method of the composite photocatalytic material, the specific steps are as follows:

[0028] (1) Add 2g of tin tetrachloride pentahydrate, 1.0g of sodium hydroxide, 0.2mL of 2mmol / L chloroplatinic acid solution, and 1.0g of polyvinylpyrrolidone (PVP) into 30mL of deionized water and stir for 15min to obtain a solution A, the stirring speed is 500 rpm;

[0029] (2) Add 30 mL of ethanol to solution A in step (1), stir for 20 min to obtain solution B, and the stirring speed is 500 rpm;

[0030] (3) Add 6 g of zinc sulfate to 30 mL of deionized water, stir for 15 minutes to obtain solution C, and the stirring speed is 500 rpm;

[0031] (4) Add 4g of ammonium bicarbonate to 20mL of deionized water, stir for 15min to obtain solution D, add solution D to solution C of step (3), stir for 35min under 60℃ water bath conditions to form solution E, stirring speed 500 revolutions per minute;

[0032] (5) Add the solution E of step (4)...

Embodiment 2

[0036] A ZnO-SnO doped with metallic platinum 2 The preparation method of the composite photocatalytic material, the specific steps are as follows:

[0037] (1) Add 1.5g of tin tetrachloride pentahydrate, 2.0g of sodium hydroxide, 0.1mL of 2mmol / L chloroplatinic acid solution, 1.5g of polyvinylpyrrolidone (PVP) into 40mL of deionized water and stir for 20min to obtain Solution A, the stirring speed is 750 rpm;

[0038] (2) Add 40 mL of ethanol to solution A in step (1), stir for 30 min to obtain solution B, and the stirring speed is 750 rpm;

[0039] (3) Add 4 g of zinc sulfate to 40 mL of deionized water, stir for 20 minutes to obtain solution C, and the stirring speed is 750 rpm;

[0040] (4) Add 6g of ammonium bicarbonate to 40mL of deionized water, stir for 20min to obtain solution D, add solution D to solution C of step (3), stir for 20min under 40℃ water bath conditions to form solution E, stirring speed 750 revolutions per minute;

[0041] (5) Add the solution E of step (4) to ...

Embodiment 3

[0044] A ZnO-SnO doped with metallic platinum 2 The preparation method of the composite photocatalytic material, the specific steps are as follows:

[0045] (1) Add 2.5g tin tetrachloride pentahydrate, 1.5g sodium hydroxide, 0.4mL 2mmol / L chloroplatinic acid solution, 0.5g polyvinylpyrrolidone (PVP) into 20mL deionized water and stir for 10min to obtain Solution A, the stirring speed is 1000 rpm;

[0046] (2) Add 20 mL of ethanol to solution A in step (1), stir for 40 minutes to obtain solution B, and the stirring speed is 1000 rpm;

[0047] (3) Add 8g of zinc sulfate to 20mL of deionized water, stir for 10min to obtain solution C, the stirring speed is 1000 rpm;

[0048] (4) Add 5g of ammonium bicarbonate to 30mL of deionized water, stir for 10min to obtain solution D, add solution D to solution C of step (3), stir for 50min under 50℃ water bath conditions to form solution E, the stirring speed is 1000 revolutions per minute;

[0049] (5) Add the solution E of step (4) to the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com