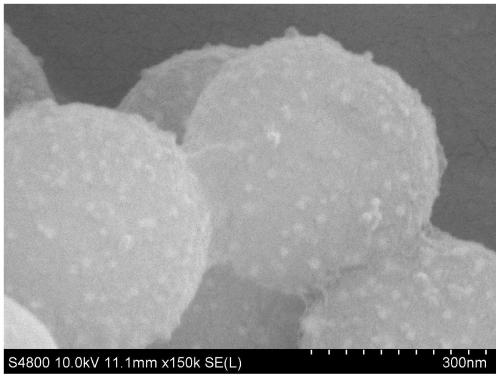

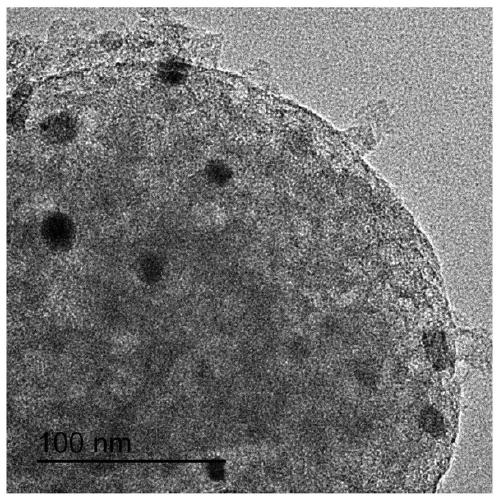

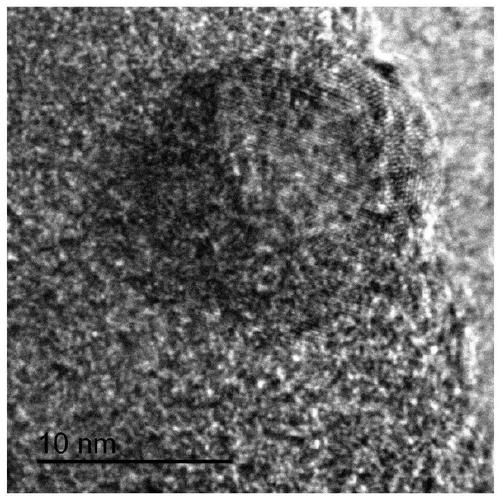

In situ embedding of binary transition metal nanoparticles into porous nitrogen-doped carbon spheres and its preparation method

A technology of transition metals and nanoparticles, applied in the direction of carbon preparation/purification, nanotechnology, nanotechnology, etc., can solve the problems of limiting the application of negative electrode materials, not being effectively used, and limitations, etc., to achieve universality and benefit Adsorption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Add transition metal nitrate cobalt nitrate and nickel nitrate in a molar ratio of 1:1 to the hydroalcoholic solution mixed with deionized water and absolute ethanol in a volume ratio of 1:0.4, and stir ultrasonically for 0.5h to obtain a concentration of 3mmol / L solution A;

[0040] Step 2: Take melamine and resorcinol with a mass ratio of 1:0.8, mix them evenly, add them to solution A, and stir magnetically at a stirring rate of 500r / min for 40min to obtain suspension B, wherein the mass-volume ratio of melamine to solution A is For 1g: 170mL;

[0041]Step 3: According to the volume ratio of formaldehyde solution and solution A is 1:80, take the formaldehyde solution and add it to the suspension B drop by drop at a rate of 2 s / drop, and stir while adding, at a rate of 100r / min Stir magnetically for 10 minutes to obtain suspension C. According to the volume ratio of ammonia water and formaldehyde solution of 1:0.9, take ammonia water and add it dropwise to sus...

Embodiment 2

[0050] Step 1: Add transition metal nitrate cobalt nitrate and ferric nitrate in a molar ratio of 1:1.2 to the hydroalcoholic solution mixed with deionized water and absolute ethanol in a volume ratio of 1:0.6, and stir ultrasonically for 1 hour to obtain a concentration of 8 mmol / L solution A;

[0051] Step 2: Take melamine and resorcinol with a mass ratio of 1:1.2, mix them evenly, add them to solution A, and magnetically stir at a stirring rate of 400r / min for 60min to obtain suspension B, wherein the mass-volume ratio of melamine to solution A For 1g: 150mL;

[0052] Step 3: According to the volume ratio of formaldehyde solution to solution A is 1:170, take formaldehyde solution and add it dropwise to suspension B at a rate of 3 s / drop, and stir while adding, at a rate of 200r / min Stir magnetically for 20 minutes to obtain suspension C. According to the volume ratio of ammonia water and formaldehyde solution as 1:2, take ammonia water and add it dropwise to suspension C ...

Embodiment 3

[0056] Step 1: Add transition metal nitrate cobalt nitrate and silver nitrate at a molar ratio of 1:0.9 to the hydroalcoholic solution mixed with deionized water and absolute ethanol at a volume ratio of 1:0.5, and stir ultrasonically for 0.8 hours to obtain a concentration of 5mmol / L solution A;

[0057] Step 2: Take melamine and resorcinol with a mass ratio of 1:1 and mix them evenly, then add them to solution A, stir magnetically at a stirring rate of 550r / min for 35min to obtain suspension B, wherein the mass-volume ratio of melamine to solution A For 1g: 120mL;

[0058] Step 3: According to the volume ratio of formaldehyde solution and solution A is 1:100, take the formaldehyde solution and add it to the suspension B drop by drop at a rate of 2 s / drop, and stir while adding, at a rate of 150r / min Stir magnetically for 15 minutes to obtain suspension C. According to the volume ratio of ammonia water and formaldehyde solution as 1:1, take ammonia water and add it dropwise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com