Application of calcium sulfate and/or calcium phosphate to removing TOC in wet-method metallurgical raffinate

A technology of hydrometallurgy and raffinate, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of many equipments, incomplete oxidation, high cost, etc. The effect of low reliability, high utilization rate and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

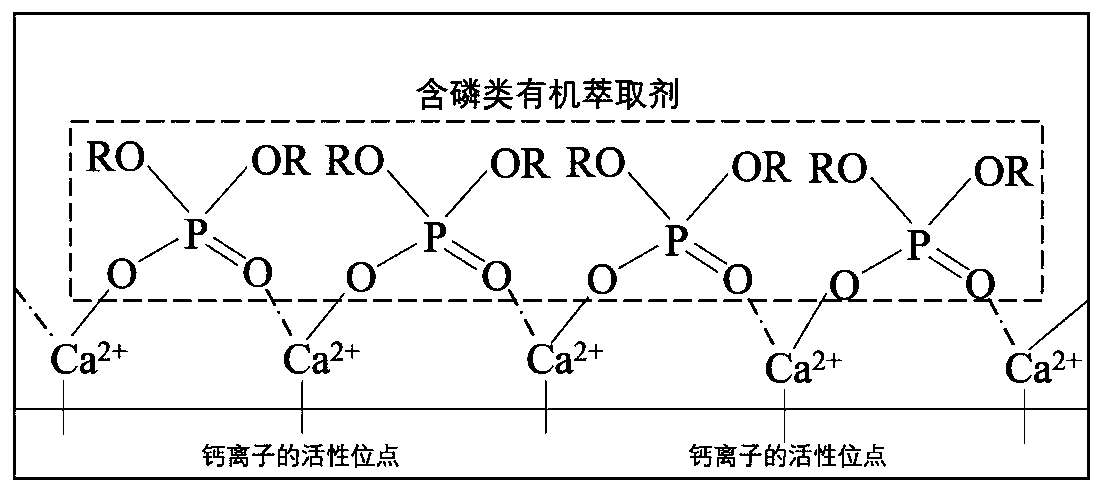

Problems solved by technology

Method used

Image

Examples

Embodiment 1

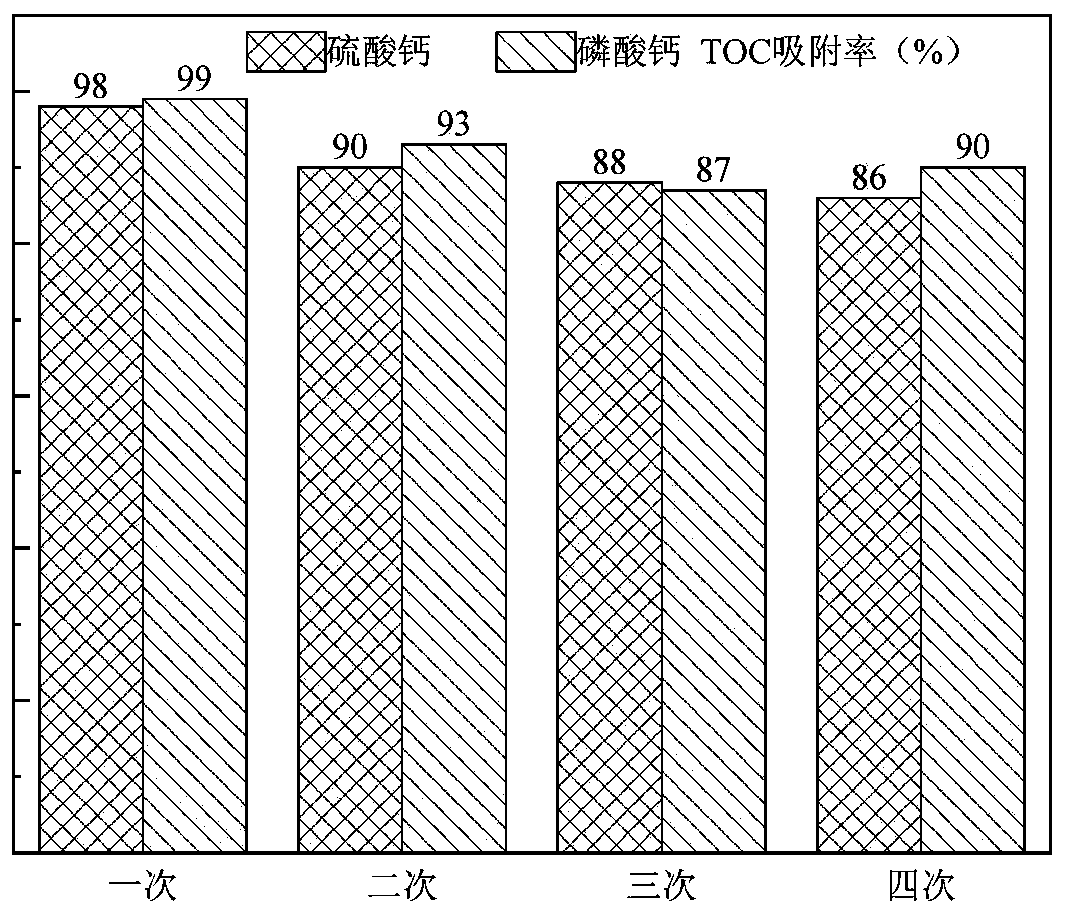

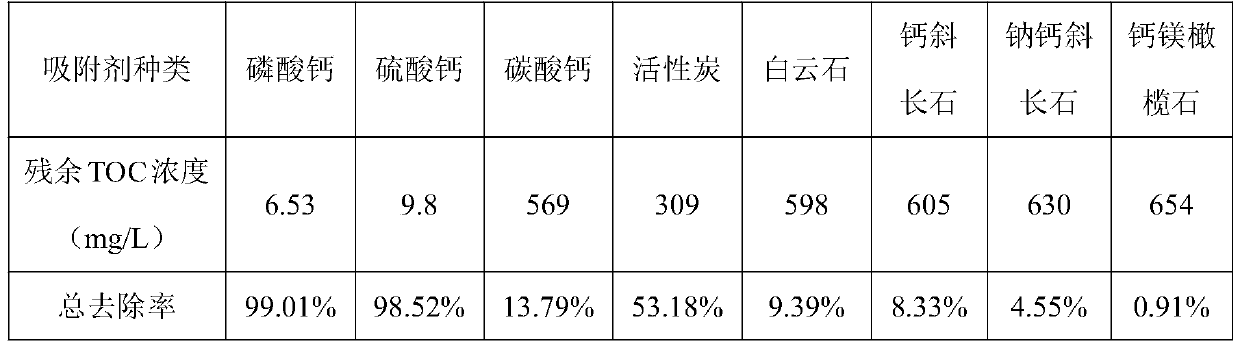

[0034] The solid adsorbent is calcium sulfate and calcium phosphate, and the mass ratio of the two is 1:3.

[0035] The solid adsorbent of the present invention is applied to the raffinate obtained from the nickel-removing process of wet zinc smelting of Mengzi Mining and Metallurgical Environmental Protection Technology Branch. The nickel ion concentration in the iron removal preliquid is 1.03g / L, and the nickel is removed by extraction. The extractant is phosphorus-containing organic P204, and the dispersant is kerosene. The TOC of the raffinate obtained after the iron removal is completed and the liquid separation is 1300 mg / L.

[0036] The action mode of the solid adsorbent is as follows: the slurry prepared by the solid adsorbent is uniformly and continuously added to the leachate, and after the magnetic stirring and the adsorption reaction are completed, the adsorbent reaction product enters the underflow solid phase. The initial pH of the extract is 2.5 and the final pH is ...

Embodiment 2

[0038] The solid adsorbent is calcium sulfate.

[0039] The solid adsorbent of the present invention is applied to the raffinate obtained from the cobalt removal process of the hydrometallurgical zinc smelting of Chihong Zinc and Germanium Huize Smelting Branch. The cobalt ion concentration in the iron removal preliquid is 4.54g / L, and the cobalt is removed by extraction. , The extractant is phosphorus-containing organic P507, and the dispersant is kerosene. The TOC of the raffinate obtained after the iron removal is completed and the liquid separation is 660 mg / L.

[0040] The action mode of the solid adsorbent is as follows: the slurry prepared by the solid adsorbent is uniformly and continuously added to the leachate, and after the magnetic stirring and the adsorption reaction are completed, the adsorbent reaction product enters the underflow solid phase. The initial pH of the extract is 3.2 and the final pH is 3.4, which basically does not change the acid-base balance of the s...

Embodiment 3

[0042] The solid adsorbent is calcium sulfate and calcium phosphate with crystal water, the mass ratio of the two is 1:5.

[0043] The solid adsorbent of the present invention is applied to the raffinate obtained from the copper-removing process of wet zinc smelting in the third workshop of the electric nickel smelter of Jinchuan Nickel Smelter. The copper ion concentration in the pressurized oxygen leaching solution is 1.83g / L, and the copper is removed by extraction. , The extractant is phosphorus-containing organic P204, and the dispersant is kerosene. The TOC of the raffinate obtained after the iron removal is completed and the liquid separation is 980 mg / L.

[0044] The action mode of the solid adsorbent is as follows: the slurry prepared by the solid adsorbent is uniformly and continuously added to the leachate, and after the magnetic stirring and the adsorption reaction are completed, the adsorbent reaction product enters the underflow solid phase. The initial pH of the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com