Preparation method of flavonoid magnetic molecularly imprinted polymer

A magnetic molecular imprinting and polymer technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of large consumption of organic solvents, low sensitivity, long analysis process, etc., and achieve fast binding kinetics and high specificity. Ability to identify, prepare simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: The preparation method of this flavonoid magnetic molecularly imprinted polymer is as follows:

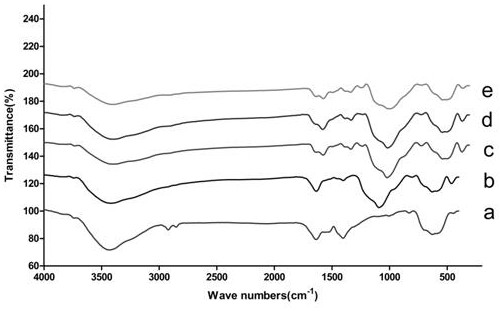

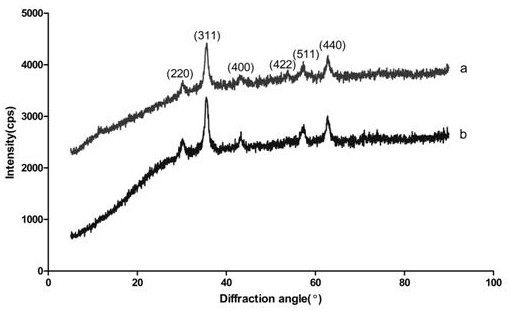

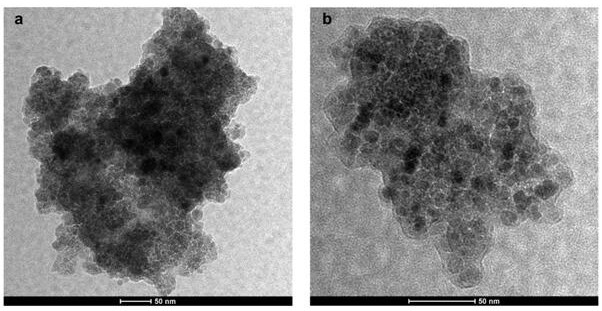

[0029] (1) FeCl 2 4H 2 O and FeCl 3 ·6H 2 O was dissolved in deionized water and stirred at 75°C under nitrogen protection for 60 minutes; then 1 mL of oleic acid was added dropwise to each 100 mL of the mixed solution for 30 minutes, and then 10 mL of ammonium hydroxide was added dropwise to each 100 mL of the mixed solution for 30 minutes. After completion, the product was naturally cooled to room temperature, separated under the action of an external magnetic field, and the solid was washed with ethanol and deionized water for 3 times, and dried in vacuum at 40°C to obtain Fe 3 o 4 Magnetic nanoparticles, where FeCl 2 4H 2 O and FeCl 3 ·6H 2 The mass ratio of O is 1:2.5, Fe 2+ The concentration in deionized water is 4mmol / L;

[0030] (2) Incorporate step (1) Fe 3 o 4 Ultrasonic dispersion of magnetic nanoparticles in 80% ethanol solution, Fe3 o 4 T...

Embodiment 2

[0041] Example 2: The preparation method of this flavonoid magnetic molecularly imprinted polymer is as follows:

[0042] (1) FeCl 2 4H 2 O and FeCl 3 ·6H 2 O was dissolved in deionized water, and stirred at 80°C for 45 minutes under nitrogen protection; then 3 mL of oleic acid was added dropwise to each 100 mL of the mixed solution for 40 minutes, and then 15 mL of ammonium hydroxide was added dropwise to each 100 mL of the mixed solution for 40 minutes. After completion, the product was naturally cooled to room temperature, separated under the action of an external magnetic field, the solid was washed with ethanol and deionized water for 4 times, and dried in vacuum at 60°C to obtain Fe 3 o 4 Magnetic nanoparticles, where FeCl 2 4H 2 O and FeCl 3 ·6H 2 The mass ratio of O is 1:3, Fe 2+ The concentration in deionized water is 5mmol / L;

[0043] (2) Incorporate step (1) Fe 3 o 4 Ultrasonic dispersion of magnetic nanoparticles in 85% ethanol solution, Fe 3 o 4 The ...

Embodiment 3

[0046] Example 3: The preparation method of this flavonoid magnetic molecularly imprinted polymer is as follows:

[0047] (1) FeCl 2 4H 2 O and FeCl 3 ·6H 2 O was dissolved in deionized water and stirred at 85°C under nitrogen protection for 30 minutes; then 5 mL of oleic acid was added dropwise to each 100 mL of the mixed solution for 55 minutes, and then 12 mL of ammonium hydroxide was added dropwise to each 100 mL of the mixed solution for 50 minutes. After completion, the product was naturally cooled to room temperature and separated under the action of an external magnetic field. The solid was washed three times with ethanol and deionized water in turn, and dried in vacuum at 50°C to obtain Fe 3 o 4 Magnetic nanoparticles, where FeCl 2 4H 2 O and FeCl 3 ·6H 2 The mass ratio of O is 1:4, Fe 2+ The concentration in deionized water is 6mmol / L;

[0048] (2) Incorporate step (1) Fe 3 o 4 Ultrasonic dispersion of magnetic nanoparticles in 90% ethanol solution, Fe 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com