Method for preparing papermaking sizing emulsion based on cationic Janus particles

A cationic, sizing emulsion technology, which is applied in papermaking, textiles, papermaking, paper coatings, etc., can solve the problems of high cost, difficult synthesis, and inability to realize industrial scale production, so as to improve utilization rate, avoid negative impact, and simple The effect of efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

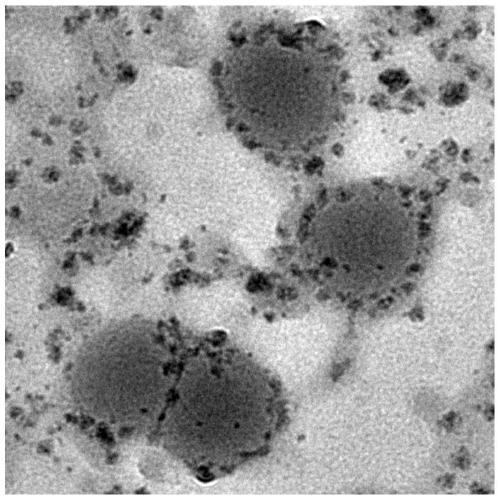

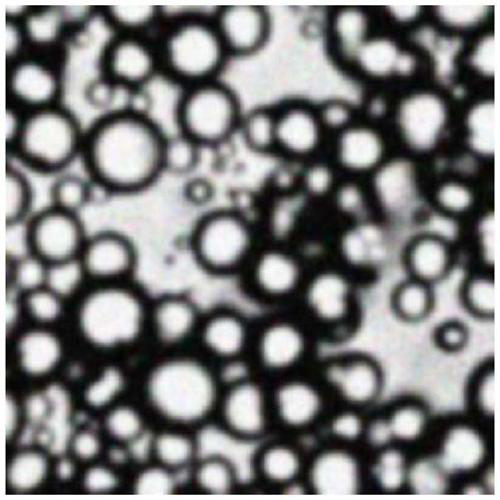

Image

Examples

Embodiment 1

[0033] Mix 5g of cationic starch with 200g of deionized water and stir evenly. Raise the reaction temperature to 85°C and keep stirring for 30 minutes. Continue stirring for 10 minutes after butyl acrylate, adjust the reaction temperature to 75° C., add 0.5 g of ammonium persulfate, and keep the reaction for 2 hours to obtain a seed emulsion stabilized by cationic starch.

[0034] Add 20g of methacryloyloxyethyltrimethylammonium chloride to the cationic starch-stabilized seed emulsion and stir thoroughly, add 0.25g of 2,2'-azobisisobutylamidine hydrochloride, and keep warm for 4 Hours, the cationic Janus particle emulsion was obtained. Take 4g of cationic Janus particle emulsion, add 100g of deionized water, adjust the pH of the dispersion to 7.5, add 110g of alkenyl succinic anhydride, and mix thoroughly to obtain a papermaking sizing emulsion with stable cationic Janus particles.

Embodiment 2

[0036]Mix 10g of starch dextrin and 300g of deionized water and stir evenly. Raise the reaction temperature to 80°C and keep stirring for 60 minutes. ester, 15g ethyl acrylate, and 5g acrylic acid, and then continue to stir for 20 minutes. After adjusting the reaction temperature to 40°C, add 0.25g potassium persulfate and 0.1g sodium bisulfite, and keep warm for 4 hours to obtain starch dextrin-stabilized Seed lotion.

[0037] Add 10g of diallyldimethylammonium chloride to the starch dextrin-stabilized seed emulsion and stir thoroughly, add 0.17g of 2,2'-azobisisobutylamidine hydrochloride, and keep warm for 6 hours to obtain Cationic Janus particle emulsion. Take 10g of cationic Janus particle emulsion, add 120g of deionized water, adjust the pH of the dispersion to 7, add 300g of alkyl ketene dimer, and mix thoroughly to obtain a papermaking sizing emulsion with stable cationic Janus particles.

Embodiment 3

[0039] Mix 15g of enzymatic starch with 400g of deionized water and stir evenly. Raise the reaction temperature to 70°C and keep stirring for 40 minutes. After the enzymatic starch is gelatinized, nitrogen gas is introduced, and 50g of methyl acrylate, 25g of butyl After 25g of isooctyl acrylate, continue to stir for 30 minutes, adjust the reaction temperature to 50°C, add 0.5g of dicumyl peroxide and 0.5g of sodium thiosulfate, and keep the temperature for 4 hours to obtain seeds stabilized by enzymatic starch lotion.

[0040] Add 50g of diallyldimethylammonium chloride to the seed emulsion stabilized by enzymatic starch and stir thoroughly, add 0.7g of 2,2'-azobisisobutylamidine hydrochloride, and keep it warm for 12 hours to obtain Cationic Janus particle emulsion. Take 50g of cationic Janus particle emulsion, add 900g of deionized water, adjust the pH value of the dispersion to 8, add 1000g of alkyl ketene dimer, 50g of rosin, and mix thoroughly to obtain paper sizing wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com