Preparation method of acid and alkali resistant nano-antirust paint

An anti-rust coating, acid and alkali resistance technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of normal production, non-environmental protection, toxic solvents, etc., to prevent corrosion and rust, excellent anti-rust performance, The effect of increasing the degree of fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

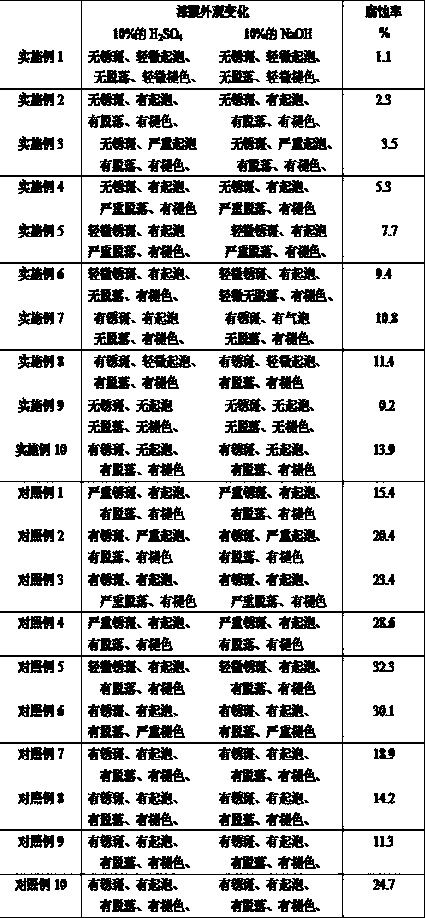

Examples

Embodiment 1

[0015] A preparation method of acid and alkali resistant nano antirust coating, the method comprises the following steps:

[0016] Step 1. Disperse 0.5mol polyaniline monomer in 100ml sulfosalicylic acid solution with a concentration of 0.5M and sonicate for 30min, then add oxidized vermiculite powder (the molar ratio of oxidized vermiculite powder to polyaniline monomer is 3:1) , stirred, ultrasonic 30min;

[0017] Step 2. Slowly add ammonium persulfate to the above solution (the molar ratio of polyaniline monomer to ammonium persulfate is 1:1), stir and then filter with suction, wash the filtered product with water and alcohol for several times until the cleaning solution is neutral , and then vacuum-dry the filtered product at 65°C to obtain the precursor powder;

[0018] Step 3, add 5g nano-TiO to the above-mentioned precursor powder 2 Pigment, and continue to add 3g of epoxy resin, 1.5g of polyamide curing agent and 4ml of deionized water, stir well, and obtain the acid...

Embodiment 2

[0025] Step 1. Disperse 0.5mol of polyaniline monomer in 100ml of sulfosalicylic acid solution with a concentration of 0.5M and sonicate for 30 minutes, then add oxidized vermiculite powder (the molar ratio of oxidized vermiculite powder to polyaniline monomer is 2:1) , stirred, and ultrasonicated for 30 min; the rest of the preparation was the same as in Example 1.

Embodiment 3

[0027] Step 1. Disperse 0.5mol of polyaniline monomer in 100ml of sulfosalicylic acid solution with a concentration of 0.5M and sonicate for 30 minutes, then add oxidized vermiculite powder (the molar ratio of oxidized vermiculite powder to polyaniline monomer is 1:1) , stirred, and ultrasonicated for 30 min; the rest of the preparation was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com