Self-supporting SiOx-based composite negative electrode material and preparation method thereof

A negative electrode material, self-supporting technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as poor conductivity and difficult preparation of composite negative electrodes, improve surface characteristics, improve electron transport performance, and enrich pores effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) 20g of graphene foam (G-F) is placed in a nitrogen-protected tube furnace, and the temperature in the furnace is kept at 300°C;

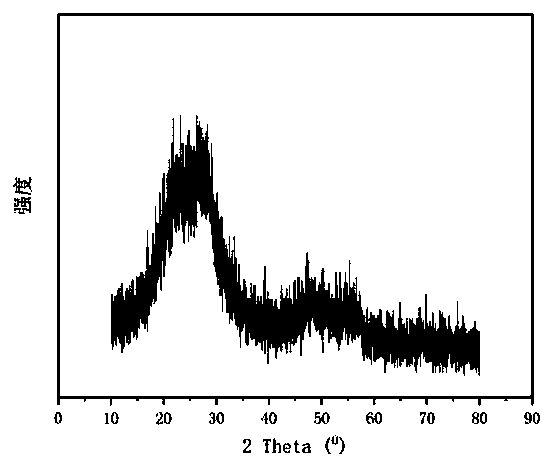

[0042] (2) After mixing 28g of silicon powder and 55g of silicon dioxide powder evenly and compacting them, place them in a vacuum tube furnace, keep the vacuum in the furnace at 10Pa, raise the temperature of the tube furnace to 1400°C, and keep it warm for 5 hours; and generate SiO x The gas is passed into the tube furnace in the previous step for surface deposition, the gas flow rate is 20ml / min, and the three-dimensional G-F@SiO x composite materials;

[0043] (3) Take 20g G-F@SiO x Put it in a tube furnace, pass it into a mixed atmosphere of methane and hydrogen, and raise the temperature to 700°C for 5 hours to obtain G-F@SiO x @C Composite anode material.

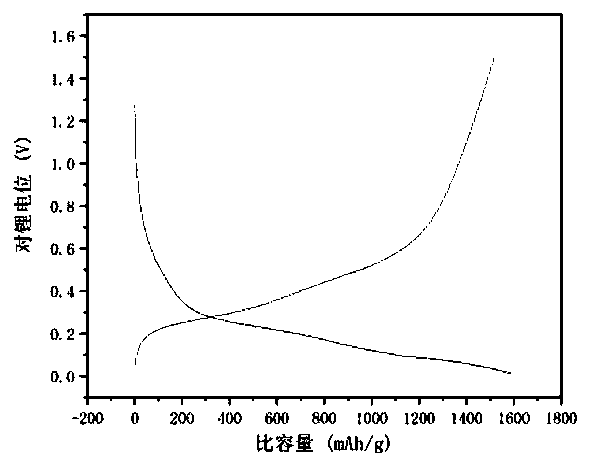

[0044] The obtained self-supporting material was directly used as a negative electrode sheet to assemble a button battery. Electrochemical tests show that its first coulomb...

Embodiment 2

[0046] (1) 10g of graphene foam (G-F) is placed in a nitrogen-protected tube furnace, and the temperature in the furnace is maintained at 300°C;

[0047] (2) After mixing 14g of silicon powder and 33g of silicon dioxide powder and compacting them evenly, place them in a vacuum tube furnace, keep the vacuum in the furnace at 50Pa, raise the temperature of the tube furnace to 1400°C, and keep it warm for 5h; and generate SiO x The gas is passed into the tube furnace in the previous step for surface deposition, the gas flow rate is 50ml / min, and the three-dimensional G-F@SiO x composite materials;

[0048] (3) Take 10g G-F@SiO x , and soak it in 50% glucose solution, after completely infiltrating, take it out and dry it, then put it in a tube furnace, keep it at 800°C for 4h, and get G-F@SiO x @C Composite anode material.

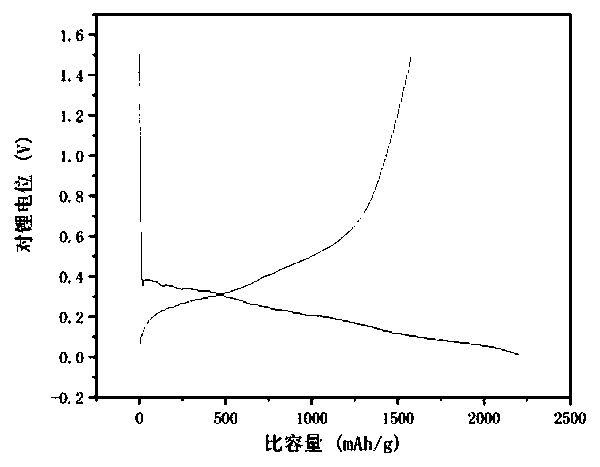

[0049] The obtained self-supporting material was directly used as a negative electrode sheet to assemble a button battery. Electrochemical tests show tha...

Embodiment 3

[0051] (1) Place 10g of copper foam (Cu-F) in a nitrogen-protected tube furnace, and keep the temperature in the furnace at 200°C;

[0052] (2) After mixing 14g of silicon powder and 32g of silicon dioxide powder and compacting them evenly, place them in a vacuum tube furnace, keep the vacuum in the furnace at 20Pa, raise the temperature of the tube furnace to 1450°C, and keep it warm for 5 hours; and generate SiO x The gas is passed into the tube furnace in the previous step for surface deposition, and the gas flow rate is 100ml / min to obtain a three-dimensional Cu-F@SiO x composite materials;

[0053] (3) Take 10g Cu-F@SiO x , placed in a tube furnace, fed with a mixed atmosphere of methane and hydrogen, and heated to 700 ° C, the holding time is 4h, to obtain Cu-F@SiO x @C Composite anode material.

[0054] The obtained self-supporting material was directly used as a negative electrode sheet to assemble a button battery. Electrochemical tests show that its first coulom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com