Method for dealkalizing aluminum-reinforced red mud and separating and recovering aluminum and iron

A separation and recovery, red mud technology, applied in industrial flue gas pollutant control, metallurgical field and environmental protection field, can solve the problems of complex technology, difficult industrial production cost, high energy consumption, to strengthen the effect of dealkalization, reduce industrial The effect of running cost and low metal impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

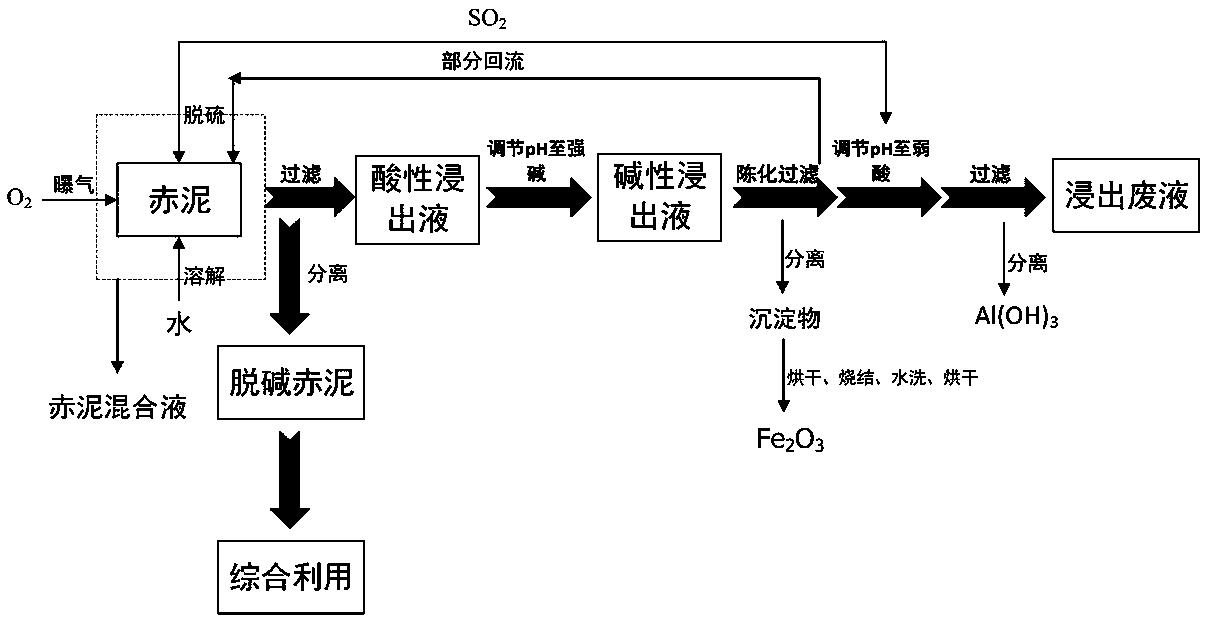

[0042] A method for strengthening red mud dealkalization with aluminum and separating and recovering aluminum and iron, comprising the following steps:

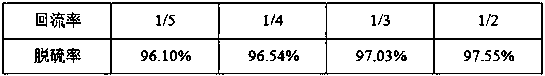

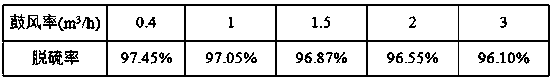

[0043] S1. Grinding the red mud to 100 mesh and then dissolving it in a slurry liquid. The slurry liquid is water and filtered alkaline leaching liquid, and stirred evenly to obtain a red mud slurry with a liquid-solid ratio of 7:1. Using the tail gas produced by burning pyrite in the rotary roasting kiln, use an air compressor to prepare the tail gas into a certain concentration of SO in the buffer bottle 2 Flue gas, followed by a blast volume of 0.4m 3 Sulfur-containing flue gas is introduced into the red mud slurry at a speed of 1 / h for reverse contact and mixing, aeration and oxidation to obtain red mud mixed liquid, and the SO 2 The gas flow rate is 12L / m 3 red mud slurry, the O 2 with SO 2 The gas feed volume ratio is 1:1, and the pH of the red mud mixture reaches below 3; after filtering, washing is performed for 3...

Embodiment 2

[0046] A method for strengthening red mud dealkalization with aluminum and separating and recovering aluminum and iron, comprising the following steps:

[0047] S1. Grinding the red mud to 200 mesh and then dissolving it in a slurry liquid, the slurry liquid is water and filtered alkaline leaching liquid, stirring evenly to obtain a red mud slurry with a liquid-solid ratio of 7:1. Using the tail gas produced by burning pyrite in the rotary roasting kiln, use an air compressor to prepare the tail gas into a certain concentration of SO in the buffer bottle 2 flue gas, followed by a blast volume of 1 m 3 Sulfur-containing flue gas is introduced into the red mud slurry at a speed of 1 / h for reverse contact and mixing, aeration and oxidation to obtain red mud mixed liquid, and the SO 2 The gas flow rate is 1L / m 3 red mud slurry, the O 2 with SO 2 The gas volume ratio is 1:5, and the pH of the red mud mixture reaches below 3; after filtering, washing is carried out for 8 times t...

Embodiment 3

[0050] A method for strengthening red mud dealkalization with aluminum and separating and recovering aluminum and iron, comprising the following steps:

[0051] S1. Grinding the red mud to 120 mesh and then dissolving it in a slurry liquid, the slurry liquid is water and filtered alkaline leaching liquid, stirring evenly to obtain a red mud slurry with a liquid-solid ratio of 7:1. Using the tail gas produced by burning pyrite in the rotary roasting kiln, use an air compressor to prepare the tail gas into a certain concentration of SO in the buffer bottle 2 Flue gas, followed by a blast volume of 1.5m 3 Sulfur-containing flue gas is introduced into the red mud slurry at a speed of 1 / h for reverse contact and mixing, aeration and oxidation to obtain red mud mixed liquid, and the SO 2 The gas flow rate is 4L / m 3 red mud slurry, the O 2 with SO 2 The gas feed volume ratio is 1:2, and the pH of the red mud mixture reaches below 3; after filtering, washing is performed for 4 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com