Raw material composition and method for preparing edible vinegar through straw enzymolysis fermentation and application thereof

A technology of raw material composition and straw, which is applied to fertilizers made from biological wastes, applications, vinegar preparation, etc. The effect of reducing the phenomenon of fermentation inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0041] This embodiment provides the specific implementation of Yizhong vinegar koji, which is basically the same as in Example 1, except that the mass ratio of the acetic acid bacteria suspension to the paste medium is 3:50, and it is placed for 30 days after inoculation.

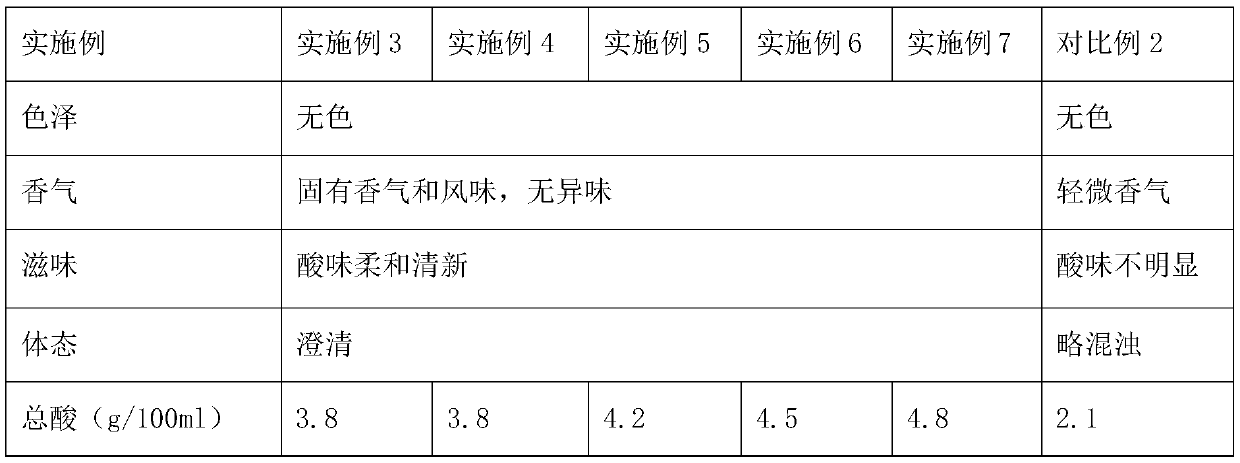

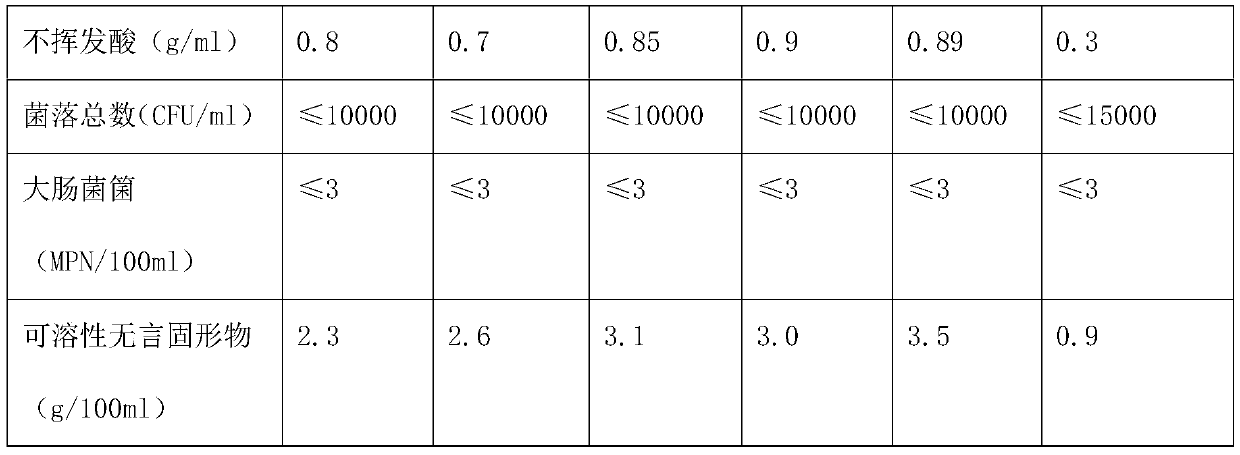

Embodiment 3

[0042] This example of Example 3 provides a specific implementation method for preparing vinegar by enzymolysis and fermentation of straw, including the following steps:

[0043] Raw material pretreatment: 40kg of fresh corn stalks, 10kg of sweet sorghum stalks, 10kg of barley stalks, 10kg of wheat stalks and 10kg of corn stalks were washed, dried, chopped and homogenized to obtain straw homogenate; 0.8kg of enzymolysis agent was added, It includes phosphate buffer with a pH value of 5 and a concentration of 0.5M and compound enzymes. The compound enzymes include endoglucanase, exoglucanase, β-glucosidase, pectinase, protease, α-amylase and glucoamylase each 640,000 FPU, mix well, stand for 4h;

[0044] Alcoholic fermentation: the pretreated straw homogenate is sealed and fermented at 28-33°C for 60 days to obtain fermented mash;

[0045] Vinegar fermentation: add vinegar koji described in Example 1 to the alcohol fermentation mash, mix well, and ferment under aeration at 30-...

Embodiment 4

[0047] This example of Example 4 provides a specific implementation method for preparing vinegar by enzymolysis and fermentation of straw, including the following steps:

[0048] Raw material pretreatment: 50kg of fresh corn stalks, 10kg of sweet sorghum stalks, 10kg of barley stalks, 10kg of wheat stalks and 10kg of corn stalks were washed, dried, chopped, and homogenized to obtain a straw homogenate; 10kg of dry straw powder was added, and 0.1 kg Aspergillus niger powder, the concentration of live bacteria is 8×10 10 CFU / g; Add 1.8kg of enzymatic hydrolysis agent, which includes phosphate buffer with a pH value of 5 and a concentration of 0.5M and compound enzymes. The compound enzymes include endoglucanase, exoglucanase, β -Glucosidase, pectinase, protease, α-amylase and glucoamylase each 630,000 FPU, mix well, let stand for 6h;

[0049] Alcoholic fermentation: ferment the pretreated straw homogenate at 28-33°C for 15 days to obtain fermented mash;

[0050] Vinegar fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com